3-axis, 4-axis, and 5-axis machining refer to the number of axes or directions of movement that a CNC (Computer Numerical Control) machine can move its cutting tool or workpiece. These axes determine the machine’s capabilities and the complexity of the parts it can produce. Here’s a brief overview of each type:

1. 3-axis machining:

In 3-axis machining, the CNC machine moves the cutting tool along three linear axes: X, Y, and Z. This allows the machine to cut and shape the workpiece in two-dimensional (2D) and simple three-dimensional (3D) geometries. 3-axis machining is the most basic and common type of CNC machining, suitable for simple parts and prototypes.

2. 4-axis machining:

4-axis machining adds an additional rotational axis (usually the A-axis) to the existing 3-axis setup. This allows the cutting tool or workpiece to rotate around one of the linear axes, typically the X or Y axis. This added rotation enables the machine to create more complex shapes and work on multiple sides of the part without repositioning it. 4-axis machining is suitable for parts with features on multiple sides or more complex geometries than 3-axis machining can handle.

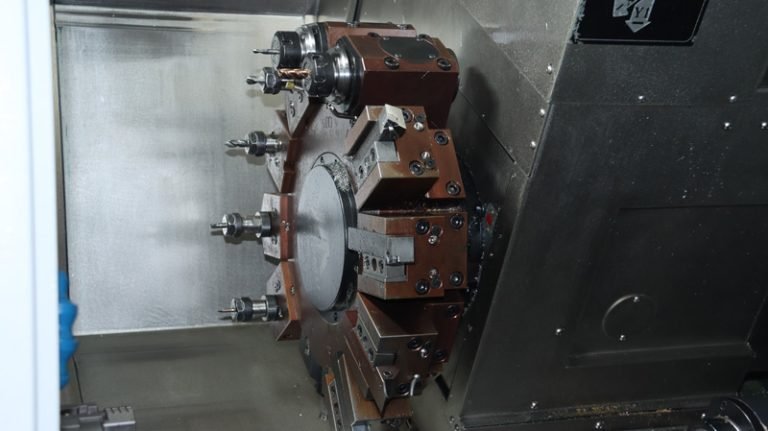

3. 5-axis machining:

In 5-axis machining, the CNC machine can move the cutting tool or workpiece along five axes: three linear axes (X, Y, and Z) and two rotational axes (usually A and B or C). This provides the greatest flexibility and precision, allowing the machine to create highly complex shapes and work on all sides of the part without repositioning. 5-axis machining is ideal for producing intricate parts, such as aerospace components, automotive parts, and advanced mold making.

In summary, the main differences between 3-axis, 4-axis, and 5-axis machining are the number of axes of movement and the complexity of the parts they can produce. As the number of axes increases, so does the machine’s ability to create more intricate and complex parts.