Casting machining refers to the process of refining and finishing a cast metal or alloy component to achieve the desired shape, size, surface finish, and dimensional accuracy.

CYCO’s state-of-the-art CNC turning and CNC milling facilities, along with knowledgeable engineering and quality personnel, allow us to precisely handle all of your part machining needs, even in the most difficult materials.

- High Precision: Standard dimensional tolerance of ±0.005mm(0.0002in)

- Various CNC machines: 3-axis, 4-axis, and 5-axis CNC machines

- Various Work Techniques: CNC milling, CNC turning, wire EDM, etc.

- Get your products and parts ready in as fast as 24 hours

- Certifications: ISO9001:2015, IATF 16949:2016

What Is Casting?

Casting is a manufacturing process in which a liquid material is poured into a mold, allowed to solidify, and then removed to reveal a fabricated part or product. This process is particularly useful for creating complex shapes and is widely used in various industries.

Casting is a versatile and widely used manufacturing method, applicable to a broad range of industries, including automotive, aerospace, art, and more. It’s an integral part of creating various components and products that we encounter in our everyday lives.

Types of Casting:

- Sand Casting - one of the most common casting processes. A pattern of the final part is pressed into a sand mold, and molten metal is poured into the mold cavity.

- Investment Casting - Also known as precision casting or lost-wax casting, this process involves creating a wax model of the part, coating it with a ceramic shell, melting the wax to leave a hollow mold, and pouring metal into the mold.

- Die Casting - This process involves forcing molten metal into a mold cavity under high pressure. It is often used for high-volume production of small to medium-sized parts with intricate details.

- Permanent Mold Casting - This process uses reusable molds made from metal to produce parts with good surface finish and dimensional accuracy.

Materials:

Various materials can be used for casting, including metals (such as aluminum, iron, steel, and copper alloys), as well as non-metals like ceramics and certain types of plastics.

Advantages:

Complex Shapes: Casting is capable of producing intricate and complex shapes that may be difficult or expensive to achieve through other manufacturing processes.

Cost-Effective for Large Quantities: Once the mold is created, producing large quantities of identical parts can be more cost-effective compared to other methods.

Why do you need casting machining

Casting itself is a manufacturing process in which molten metal or other materials are poured into a mold to create a part of a specific shape. However, the resulting castings might not always have the exact dimensions or surface quality required for their intended use. This is where casting machining comes into play.

After the casting process is completed, the cast part is often not in its final form and may have excess material, irregularities, or rough surfaces. Machining is the process of removing this excess material through various cutting, grinding, and shaping techniques to achieve the desired specifications. The goal of casting machining is to refine the part’s dimensions, improve its surface finish, ensure proper tolerances, and enhance its overall quality.

Common machining techniques used in casting machining include:

- Cutting: This involves using tools like lathes, milling machines, and drills to remove excess material and achieve precise shapes and dimensions.

- Grinding: Grinding operations use abrasive materials to smooth surfaces, remove burrs, and improve the part's surface finish.

- Milling: Milling machines use rotary cutters to remove material from a workpiece, producing various shapes and features.

- Drilling: Drilling creates holes in the workpiece using a rotating cutting tool.

CYCO Machining is one of the leading custom metal parts suppliers in China

Our advanced precision castings machining technologies create unique products, parts and shapes for all industries and applications. With more than twenty years of experience, we have enough knowledge and professional skills to customize forged parts.

We serve various applications in different industries such as automotive, industrial, electronics and medical. As a supplier of Tesla parts, CYCO has high standards and high-quality requirements in the machining of auto parts.

What are we good at?

- Forging parts (hot forging and cold forging)

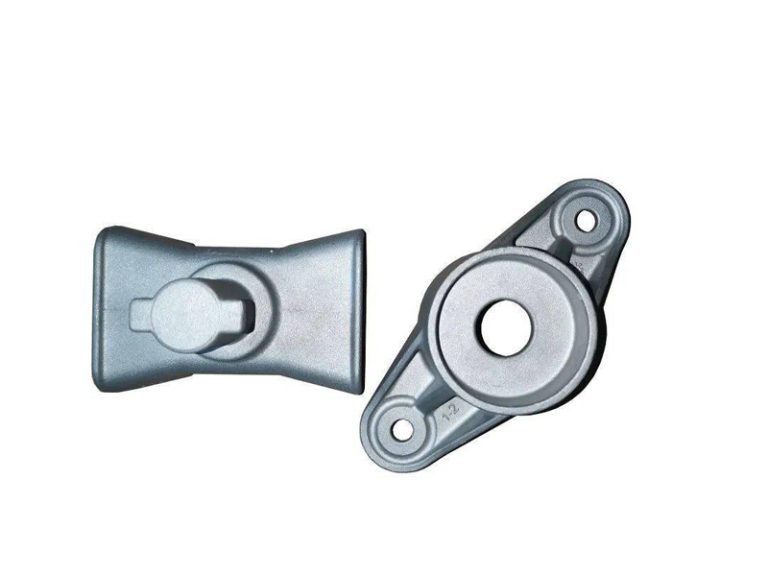

- Casting parts (precision casting and die casting)

- CNC precision machining parts

- CNC Turning

- CNC Milling

- Precision Mold Machining

- Injection Molded Plastic Parts

- Etc..

Casting Machining Surface Treatment

Surface treatment is an important aspect of casting machining to enhance the appearance, durability, and functionality of cast components. After the machining process, various surface treatment methods can be applied to improve the part’s properties. Some common surface treatment processes for castings include:

- Polishing: Polishing involves using abrasive materials to smooth the surface of the casting, creating a high-gloss finish. It's commonly used for decorative components and parts that require a reflective surface.

- Grinding: Grinding is used to remove surface imperfections, burrs, and irregularities left after machining. It improves surface finish and dimensional accuracy.

- Shot Blasting: Shot blasting involves propelling abrasive particles at high velocity onto the casting's surface. This process can remove scale, rust, and other contaminants, providing a uniform texture.

- Sandblasting: Similar to shot blasting, sandblasting uses a stream of sand or other abrasive materials to clean, smooth, or etch the surface of the casting. It's used for cleaning and preparing surfaces for further treatments like painting or coating.

- Painting and Coating: Applying paint, powder coating, or other protective coatings can improve the casting's appearance and protect it from corrosion, wear, and environmental factors.

- Anodizing: Anodizing is an electrochemical process used primarily on aluminum castings. It creates a protective oxide layer on the surface, improving corrosion resistance and allowing for color customization.

- Plating: Plating involves depositing a layer of metal onto the casting's surface through electroplating or other methods. This can enhance aesthetics, improve wear resistance, and provide protection against corrosion.

- Chemical Treatment: Chemical treatments like passivation or chromating are used to improve the corrosion resistance of metals. They involve applying chemical solutions to the surface to create a protective layer.

- Heat Treatment: Heat treatment processes can alter the mechanical properties of the casting, such as hardness and toughness. This can improve the casting's performance under specific conditions.

- Conversion Coating: Conversion coatings like phosphating or chromate conversion are used to enhance adhesion of paints or other coatings while providing some corrosion resistance.

- Electropolishing: Electropolishing is an electrochemical process that smooths and polishes the surface of the casting, removing a thin layer of material. It can improve surface finish and clean the part.

- Laser Surface Treatment: Laser technology can be used to modify the surface properties of the casting, such as hardness, texture, and heat resistance.