CNC (Computer Numerical Control) machining is a process that uses computer-controlled machines to remove material from a workpiece to create a desired shape or design. When it comes to machining ceramic parts, some specific considerations are essential due to the unique properties of ceramics.

1. **Ceramic Material Selection**: Ceramics are a broad class of materials with varying properties, such as alumina, zirconia, silicon carbide, silicon nitride, etc. The choice of ceramic material depends on the specific application and the desired properties of the final part.

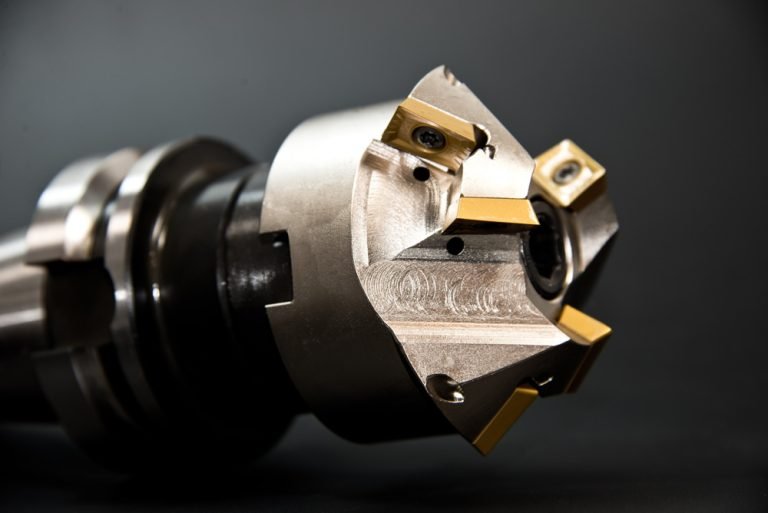

2. **Machining Challenges**: Ceramics are hard, brittle, and have low thermal conductivity, making them more challenging to machine compared to metals. The machining process must be carefully controlled to prevent cracking, chipping, or premature tool wear.

3. **Tooling Selection**: Specialized tooling is required for machining ceramics. Diamond-coated or diamond-tipped tools are commonly used because of their hardness and wear resistance when cutting ceramics.

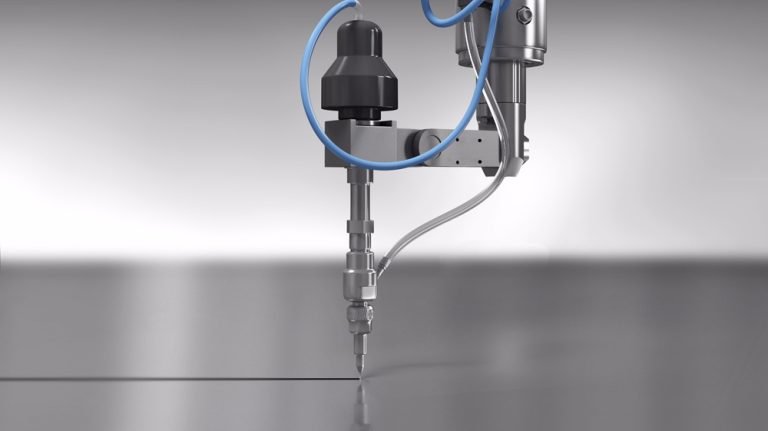

4. **Coolant and Lubrication**: Proper coolant and lubrication during the machining process are crucial to manage heat buildup and reduce the risk of thermal shock, which could lead to cracks in the ceramic part.

5. **CNC Machine Considerations**: CNC machines used for machining ceramics should have high rigidity and stability to minimize vibrations that could cause fractures in the material.

6. **Surface Finish**: Achieving a high-quality surface finish on ceramic parts can be challenging due to their hardness. Post-machining processes, such as polishing or lapping, may be required to achieve the desired surface finish.

7. **Tolerances**: Ceramics can have tight tolerances, but achieving them may be more difficult compared to metals. The material’s brittleness and the potential for small cracks or fractures during machining can impact tolerances.

8. **Quality Control**: Due to the brittle nature of ceramics, quality control is essential during and after the machining process. Non-destructive testing methods, such as X-ray or ultrasonic inspection, may be employed to detect defects.

9. **Specialized Expertise**: Machining ceramics requires specialized knowledge and experience. Manufacturers with expertise in machining ceramics should be chosen for producing high-quality parts.