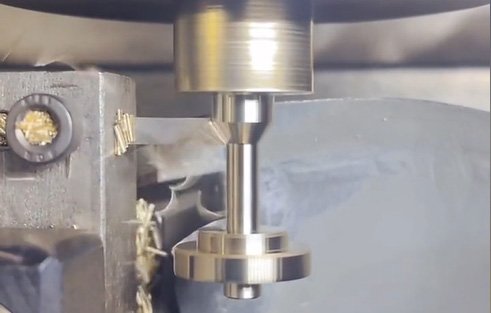

Boring is a machining process used to enlarge and improve the accuracy of an existing hole in a workpiece. It is commonly employed in metalworking, but it can also be used for other materials like wood or plastics. Boring is typically performed using a single-point cutting tool, such as a boring bar or a boring head, which removes material to achieve the desired dimensions and surface finish. Here are some technical points and aspects of the boring process:

1. Purpose: Boring is primarily done to achieve greater dimensional accuracy and a better surface finish in existing holes. It is often used in conjunction with other machining processes like drilling and reaming to create precise and concentric holes.

2. Types of Boring:

a. Line Boring: Used for elongated holes or bores that need to be accurately aligned.

b. Single-Point Boring: Involves using a single cutting tool to enlarge the hole gradually.

c. Trepanning: Creates large-diameter holes by removing a ring-shaped piece of material.

d. Jig Boring: Highly precise boring using a specialized jig and usually performed on a vertical machining center.

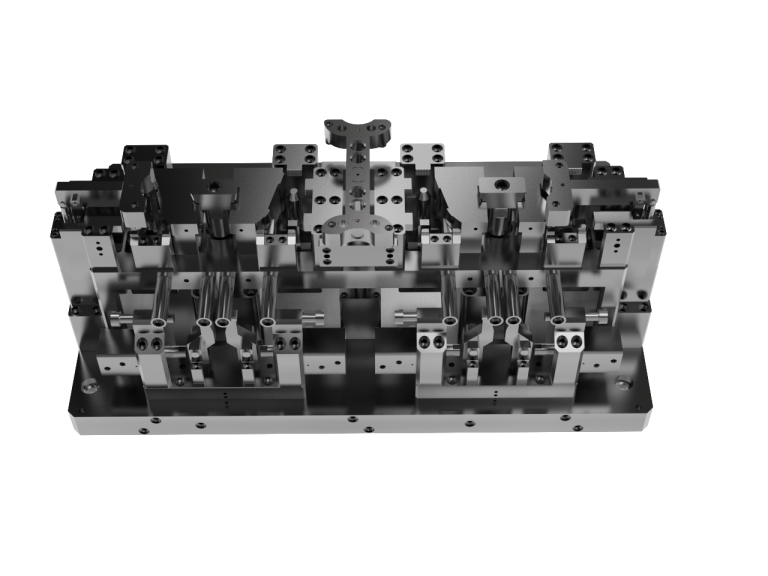

3. Boring Machines: There are various types of machines used for boring, such as:

a. Horizontal Boring Machine: The workpiece is clamped on a horizontal table, and the boring bar is inserted horizontally.

b. Vertical Boring Machine (Vertical Borer): The workpiece is mounted on a rotary table, and the boring bar is inserted vertically.

c. Jig Boring Machine: Uses a high-speed spindle and is designed for ultra-precise hole positioning and size.

4. Cutting Tools: Boring tools are usually made from high-speed steel (HSS) or carbide materials to withstand the cutting forces and temperatures. Inserts with specific geometries can be used for different materials and cutting conditions.

5. Cutting Parameters:

a. Cutting Speed: The speed at which the boring tool rotates during machining, usually measured in surface feet per minute (SFM) or meters per minute (m/min).

b. Feed Rate: The rate at which the cutting tool advances into the workpiece, typically measured in inches per revolution (IPR) or millimeters per revolution (mm/rev).

c. Depth of Cut: The amount of material removed in a single pass.

6. Workpiece Holding: Proper workpiece clamping is crucial to prevent vibrations and ensure accuracy during boring. Fixtures or jigs may be used, especially in jig boring operations.

7. Coolant and Lubrication: Boring generates heat, so using a suitable coolant or lubricant is essential to reduce tool wear and maintain dimensional accuracy.

8. Surface Finish: Boring can provide excellent surface finishes, but achieving this requires proper tool selection, cutting parameters, and tool positioning.

9. Inspection: Post-boring, the finished holes should be inspected using various measurement tools such as micrometers, dial bore gauges, or coordinate measuring machines (CMM) to ensure they meet the desired specifications.

Boring may be considered a more straightforward machining process compared to some others, but it plays a critical role in manufacturing precision parts that require accurately sized and positioned holes.