CNC machining is widely used in the application of stainless steel material due to its corrosion resistance, high strength, and aesthetic properties, making it suitable for various industrial and commercial applications. Here are some common application areas of CNC machining with stainless steel material:

– Aerospace Industry: Stainless steel is used to manufacture various parts and components of aircraft and spacecraft, such as fuselage parts, bolts, nuts, brackets, and connectors. CNC machining ensures the high precision and reliability of these components.

– Medical Equipment Manufacturing: Stainless steel is widely used in the manufacturing of medical equipment, including surgical instruments, syringes, surgical instrument casings, and medical device housings. CNC machining is used to produce precise parts for these instruments.

– Automotive Industry: Stainless steel is used in the automotive manufacturing industry for producing exhaust pipes, body parts, braking systems, and other critical components. CNC machining ensures the quality and performance of these parts.

– Food Processing Equipment: Food processing equipment is typically made from stainless steel to ensure hygiene and corrosion resistance. These equipment include food processing machinery, containers, conveyors, and pipelines.

– Chemical Industry: Stainless steel is used in the chemical industry to manufacture tanks, pipelines, reactors, and valves for handling corrosive chemicals. CNC machining is used to produce precise parts for these chemical equipment.

– Construction and Architectural Decoration: Stainless steel is commonly used in architectural applications such as exterior walls, roofs, stair railings, balustrades, door and window frames, and decorative elements. CNC machining can produce stainless steel architectural elements with complex designs.

– Energy Industry: Stainless steel is used in the energy industry to manufacture power generation equipment, pipelines, valves, pumps, and boilers. CNC machining ensures high precision and reliability for these critical equipment.

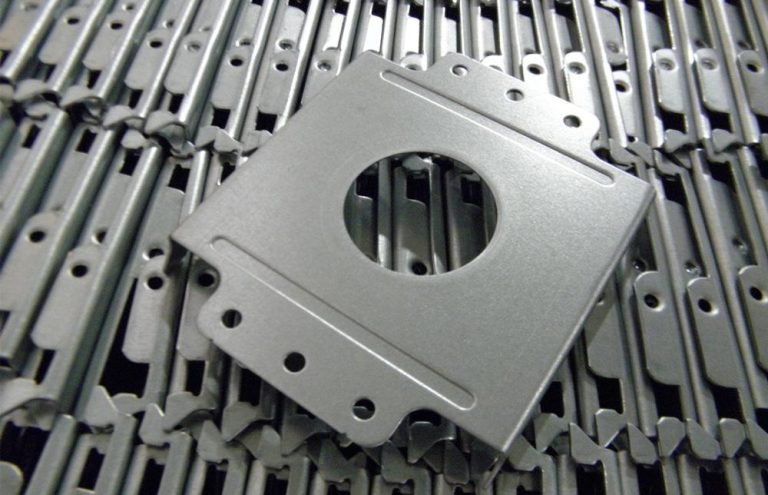

– Electronics Equipment Manufacturing: Stainless steel is used for manufacturing the casings, heat sinks, and brackets of electronic equipment. CNC machining ensures the precise dimensions and shapes of these components.

While CNC machining stainless steel offers many advantages, it also presents several challenges, including the following aspects:

– Hardness and Wear Resistance: Stainless steel is a relatively hard material with high wear resistance, which can lead to rapid tool wear during cutting. Therefore, high-quality cutting tools and regular maintenance and replacement are needed to ensure machining quality and efficiency.

– Heat Generation: Stainless steel has a relatively low thermal conductivity, making it prone to heat generation during machining. This can cause tool overheating, reducing cutting efficiency and damaging tools. Measures such as using cutting lubricants and coolants are necessary to reduce heat generation.

– Selection of Cutting Speeds and Feeds: Machining stainless steel requires selecting the appropriate cutting speeds and feeds. High speeds may lead to tool wear and decreased machining quality, while low speeds can result in low production efficiency. Therefore, experimentation and optimization are necessary to determine the best machining parameters.

– Choice of Cutting Tools: Stainless steel machining demands high-quality cutting tools, often made from hard alloys or ceramics. Proper tool selection and maintenance are crucial for successful stainless steel machining.

– Management of Machining Dust and Waste: Stainless steel machining generates a significant amount of dust and waste materials, which may pose environmental concerns. Proper disposal and cleanup measures are essential.

– Programming Complexity: Writing CNC machining programs for stainless steel can be more complex due to the material’s characteristics and the need for appropriate cutting parameters. The complexity of programming may increase manufacturing costs and time.

– Surface Quality Requirements: Stainless steel is often used in applications that require high surface quality. Therefore, extra attention is needed to ensure the smoothness and precision of the part’s surface.

In summary, CNC machining with stainless steel material finds widespread applications across various industries due to the material’s numerous advantages. However, when facing the challenges mentioned above, careful planning, proper tools and techniques, and thorough experimentation and optimization are necessary to ensure the final machining quality and efficiency.