Characteristics of aluminum machining

Second only to steel in terms of importance to industry, aluminum and aluminum alloys are the most widely used non-ferrous metals. Aluminum alloy is an important light metal material, known as the “king of light metal” because of its superior performance and a wide range of applications. It has excellent mechanical properties and good corrosion resistance, and is widely used in aerospace, automotive, electronics, construction and other fields.

Characteristics of aluminum

Aluminum has good ductility and plasticity, which makes it widely used. Its plasticity allows it to be made into aluminum foil, while its malleability allows it to be drawn into bars and wires. Aluminum also has high corrosion resistance, and when aluminum is exposed to air, it naturally forms an oxide film that prevents metal corrosion. This oxidation can also be induced by synthesis to provide stronger element protection. Aluminum’s natural protective layer makes it more resistant to corrosion than carbon steel, but it cannot compete with the chromium content of stainless steel. In addition, aluminum is a good conductor of heat and electricity, superior to carbon and stainless steel in both respects.

Compared with steel, it is faster and easier to machine. Its strength-to-weight ratio makes it ideal for many applications that require strong, rigid materials. Aluminum can also be well recycled, resulting in energy savings of up to 95% compared to the energy required to produce primary aluminum.

Compared with steel, aluminum also has some disadvantages. It is not as hard as steel and is not suitable for parts with high impact or extremely high bearing capacity. Aluminum has a much lower melting point (660℃) than steel (1400℃), so it cannot be used in high temperature environments. It also has a high coefficient of thermal expansion, so if it becomes too hot during machining, it will be difficult to maintain tight tolerances due to deformation.

Aluminium alloy

The aluminum used for CNC machining is not pure aluminum, it always contains a small amount of alloying elements. Standard aluminum still contains 99 to 99.6 percent aluminum (the element) by weight, with the remaining percentage made up of common materials such as silicon, manganese, magnesium, copper and zinc.

By slightly adjusting the content of alloying elements, countless aluminum alloys can be made. These common aluminum alloys are classified into 9 series according to the main alloying elements, and each series has some common properties. For example, 3000, 4000, 5000 series of aluminum alloy can not be heat treated, but the use of cold processing, known as work hardening.

Main aluminum grades

1000 series

A series with the largest amount of aluminum, the purity can reach more than 99.00%. Because it does not contain other metal elements, the production process is relatively single and the price is relatively cheap, it is the most commonly used series in conventional industry. At present, 1050 and 1060 are the most circulated on the market.

2000 series

2000 series aluminum is characterized by high hardness, of which the highest content of copper (about 3-5%), will also add manganese, magnesium, lead and bismuth for machinability. Its representative models are 2024, 2A16 (LY16) and 2A02 (LY6). The 2000 series belongs to aviation aluminum, which is not often used in conventional industry.

3000 series

The representative models of 3000 series aluminum alloy are 3003 and 3A21. 3000 series aluminum plate manufacturing technique is more excellent. 3000 series aluminum rod is composed of manganese element as the main component (the content is between 1.0-1.5), it is a series with good anti-rust function. 3004 aluminum also contains magnesium, which is the aluminum alloy commonly used in aluminum beverage cans.

4000 series

4A01 is the representative model of the 4000 series aluminum alloy. 4000 series aluminum plate belongs to the series with high silicon content, usually between 4.5-6.0%. 4000 series can be used for building materials, mechanical parts forging materials, welding materials, with low melting point, good corrosion resistance and other characteristics. 4043 aluminum is used as a filler rod material for welding 6000 series aluminum alloys, while 4047 aluminum is used as sheet and cladding in construction.

5000 series

The representative models of 5000 series aluminum alloy include 5052, 5005, 5083, 5A05. The main element of 5000 series is magnesium (between 3-5%), which can also be called aluminum magnesium alloy. 5000 series aluminum plate is one of the mature aluminum plate series, its main characteristics are low density, high tensile strength, high elongation, good fatigue strength, but cannot be strengthened by heat treatment. The weight of the same area of aluminum magnesium alloy is lower than that of other series, so it is widely used in conventional industry.

6000 series

6061 is the representative model of the 6000 series aluminum alloy. The series mainly contains two elements, magnesium and silicon, which are usually easy to machine and can be precipitated and hardened. For example, 6061 is a cold-treated aluminum forging product, suitable for applications with high corrosion resistance and oxidation requirements.

7000 series

7075 is the representative model of the series. 7000 series belongs to the aviation series, mainly containing zinc elements, while containing copper, chromium and magnesium. It can be hardened by precipitation to become the strongest of all aluminum alloys, belongs to the super-hard aluminum alloy. 7000 series has good wear resistance and good weldability but poor corrosion resistance.

8000 series

The 8000 series is a general term for aluminum alloys that do not belong to any other category, these alloys can contain many other elements, such as iron and lithium. For instance, 8176 aluminum contains 0.6 percent of iron and 0.1 percent of silicon by weight and is used to make wire.

9000 series

Spare alloy

Typical uses of different grades of aluminum alloy:

1050: Extruded coils for the food, chemical and brewing industries, various hoses and fireworks powder.

1060: For occasions requiring high corrosion resistance and formability, but not high strength. It is commonly used to manufacture chemical equipment.

1100: For machining parts that require good formability and high corrosion resistance but do not require high strength, such as chemical products, food industry equipment and storage containers, sheet workpieces, deep drawing or spinning concave utensils, welding parts, heat exchangers, printing plates, nameplates and reflective devices.

1145: Package, hot aluminum foil and heat exchanger.

1199: Electrolytic capacitor foil and optical reflective deposition film.

1350: Wire, conductive adhesive wire, busbar, and transformer strip.

2011: Screws and machined products requiring good machinability.

2014: For applications requiring high strength and hardness (including high temperature). Aircraft heavy duty, forgings, slabs and extrusions, wheels and structural components, multistage rocket first stage fuel tanks and spacecraft parts, truck architecture and suspension parts.

2017: The first 2000 series alloy to obtain industrial applications, and the current application range is narrow, mainly for rivets, general mechanical parts, structural and transport vehicle structural parts, propellers and accessories.

2024: Aircraft structures, rivets, missile construction, truck wheel hubs, propeller elements and various other structural parts.

2036: Auto body metal sheet parts.

2048: Aerospace and weapons structural parts.

2124: Aerospace spacecraft structural components.

2218: Aircraft and diesel engine pistons, aircraft engine cylinder heads, jet engine impellers and compressor rings.

2219: Aerospace rocket welding oxidizer tank, supersonic aircraft skin and structural parts. Working temperature is 270~300℃. Good weldability, high fracture toughness, T8 state has a high resistance to stress corrosion cracking.

2319: Weld 2219 alloy electrode and filler solder.

2618: Die forging and free forging. Piston and aeroengine parts.

2A01: Structural rivets with operating temperature less than or equal to 100℃.

2A02: Axial compressor blades of turbojet engines operating at 200 to 300℃.

2A06: Aircraft structure and aircraft structure rivets with working temperature 125~250℃.

2A10: Stronger than 2A01, used to manufacture aircraft structure rivets with operating temperatures of less than or equal to 100℃.

2A11: Aircraft of medium strength structural parts, propeller blades, transport vehicles and building structural parts. Medium strength bolts and rivets for aircraft.

2A12: Aircraft skin, spacer frame, wing ribs, wing SPAR, rivets and more. Structural parts for construction and transportation.

2A16: Aircraft parts with operating temperature of 250~300℃, welded containers and airtight cabins operating at room temperature and high temperature.

2A17: Aircraft parts with an operating temperature of 225 to 250℃.

2A50: Medium strength parts with complex shapes.

2A60: Aircraft engine air wheel, wind turbine, fan, impeller and more.

2A70: Aircraft skin, engine piston, wind turbine, wheel, etc.

2A80: Aircraft engine compressor blade, impeller, piston, ring and other parts with high operating temperature.

2A90: Aircraft engine piston.

3003: Used for machining parts that need to have good forming properties, high corrosion resistance and good weldability, or require these properties and need to have higher strength than 1000 series alloy, such as kitchenware, food and chemical products processing and storage devices, tanks for transporting liquid products, various pressure vessels and pipelines processed with sheet metal.

3004: All-aluminum can body, requiring parts with higher strength than 3003, chemical product production and storage devices, sheet and building workpiece, building tools, various lighting parts.

3105: Room partition, baffle, mobile room board gutter and downspout, sheet forming workpiece, bottle cap, bottle stopper and more.

3A21: Aircraft fuel tank, oil pipe, rivet wire, etc. Building materials, food and other industrial equipment.

5005: Similar to 3003 with moderate strength and good corrosion resistance. Used as conductor, cooker, instrument panel, shell and architectural decoration. The anodized film is brighter than the oxide film on the 3003 and harmonizes with the tone of the 6063.

5050: Sheet can be used as the lining of refrigerators and refrigerators, automobile tubes, oil pipes and agricultural irrigation pipes, and can also be machined as the back half, pipes, rods, shaped materials and wires.

5052: Good formability, corrosion resistance, candleability, fatigue strength and moderate static strength, used in the manufacture of aircraft fuel tanks, oil pipes, as well as traffic vehicles, ships sheet metal parts, instruments, street lamp brackets and rivets, hardware products, etc.

5056: Magnesium alloy and cable sheathing rivets, zippers, nails, etc. Aluminum coated wire is widely used in the machining of agricultural worm cover, and need to have high corrosion resistance of other occasions.

5083: For the need to have high corrosion resistance, good weldability and medium strength occasions, such as ships, automobiles and aircraft plate welding parts. Pressure vessels, refrigeration units, TV towers, drilling equipment, transportation equipment, missile components, armor with strict fire protection.

5086: Used for occasions requiring high corrosion resistance, good weldability and medium strength, such as ships, automobiles, aircraft, cryogenic equipment, TV towers, drilling equipment, transportation equipment, missile parts and decks, etc.

5154: Welded structures, storage tanks, pressure vessels, ship structures and offshore facilities, transport tank tank.

5182: Sheet for processing cans. Automotive body panels, control panels, reinforcing parts, brackets and other parts.

5252: Used to manufacture decorative parts with higher strength, such as decorative parts of automobiles. Bright and transparent oxide film.

5254: Hydrogen peroxide and other chemical product containers after anodizing.

5154: Welded structures, storage tanks, pressure vessels, ship structures and offshore installations, transport tanks.

5182: Sheet is used for machining can covers, car body plates, control plates, reinforcing parts, brackets and other parts.

5252: Used to manufacture decorative parts with higher strength, such as decorative parts of automobiles. It has a bright and transparent oxide film after anodizing.

5254: Containers for hydrogen peroxide and other chemical products.

5356: Welding of aluminum-magnesium alloy rods and wires with a magnesium content greater than 3%.

5454: Welded structures, pressure vessels, pipelines for marine facilities.

5456: Armor plate, high strength welded structure, storage tank, pressure vessel, ship material.

5457: Polished and anodized decorative parts for automobiles and other equipment.

5652: Storage containers for hydrogen peroxide and other chemical products.

5657: Polished and anodized decorative parts of automobiles and other equipment, but must ensure that the material has a fine grain structure in all cases.

5A02: Aircraft fuel tank and conduit, welding wire, rivets, marine structural parts.

5A03: Medium strength welded structures, cold stamping parts, welded containers, welding wires, can replace of 5A02.

5A05: Welded structural parts, aircraft skin skeleton.

5A06: Welding structure, cold die forging parts, welding and drawing container force parts, aircraft skin and bone parts.

5A12: Welded structural parts, bulletproof deck.

6005: Extruded profiles and pipes are used for structural parts that require strength greater than 6063, such as ladders, TV antennas and more.

6009: Car body plate.

6010: Sheet, car body.

6061: Various industrial structures with certain strength, weldability and high corrosion resistance are required, such as the manufacture of trucks, tower buildings, ships, trams, furniture, mechanical parts, precision machining of the pipe, rod, shaped material, plate.

6063: Industrial profiles, building profiles, irrigation pipes and extrusion materials for vehicles, benches, furniture, fences and more.

6066: Forging and welding extrusion materials.

6070: Heavy duty welded structures and extrusion materials for the automotive industry.

6101: High strength bar, electric conductor and heat dissipation equipment for buses.

6151: Used for forging crankshaft parts, machine parts and production rolling rings, which requires good forgability, high strength and good corrosion resistance.

6201: High strength conductive bar and wire.

6205: Thick plates, pedals and high impact extrusions.

6262: High stress threaded parts with better corrosion resistance than 2011 and 2017 are required.

6351: Extrusion structural parts of vehicles, water, oil and other pipelines.

6463: Building and various appliance profiles, as well as automotive trim with bright surfaces after anodizing.

6A02: Aircraft engine parts, complex forgings and die forgings.

7005: Extruded materials for the manufacture of welded structures with both high strength and high fracture toughness, such as trusses, rods, and containers for transportation vehicles; Large heat exchangers, and parts that cannot be soldered after welding; It is also used in the manufacture of sports equipment such as tennis rackets and softball bats.

7039: Freezing containers, cryogenic instruments and storage boxes, fire pressure equipment, military equipment, armor plates, missile devices.

7049: For forging parts of the same static strength as 7079-T6 alloy that require high stress corrosion cracking stress, such as aircraft and missile parts – landing gear hydraulic cylinders and extrusions. The fatigue performance of the parts is roughly equal to that of 7075-T6, and the toughness is slightly higher.

7050: Aircraft structural parts used for medium and thick plates, extruded parts, free forging and die forging parts. The requirements of alloys for the manufacture of such parts are: high resistance to spalling corrosion, stress corrosion cracking, fracture toughness and fatigue resistance.

7072: Air conditioner aluminum foil and ultra-thin strip, the coating layer of 2219, 3003, 3004, 5050, 5052, 5154, 6061, 7075, 7475, 7178 alloy sheet and pipe.

7075: For the manufacture of aircraft structures and futures, high stress structural parts and mold manufacturing with high strength and strong corrosion resistance are required.

7175: High strength structures for forging aircraft. T736 material has good comprehensive properties, including high strength, resistance to spalling corrosion and stress corrosion cracking, fracture toughness and fatigue strength.

7178: Parts requiring high compressive yield strength for the manufacture of aerospace spacecraft.

7475: Aluminum clad and unclad plates for fuselage, wing frames, stringer, etc. Other parts that must have both high strength and high fracture toughness.

7A04: Aircraft skins, screws, and stress components such as girder stringer, spacer frame, wing rib, landing gear, etc.

How to choose aluminum grade?

Hardness: Hardness is directly related to the chemical composition of the alloy. Secondly, different states also have a greater impact. From the highest hardness that can be achieved, 7 series, 2 series, 4 series, 6 series, 5 series, 3 series, 1 series, decrease in turn.

Strength: Strength is an important factor that product designers need to consider, especially when aluminum alloy components are used as structural parts, the appropriate alloy should be selected according to the pressure under. Pure aluminum has the lowest strength, while 2 series and 7 series heat-treated alloys have the highest strength. There is a positive relationship between hardness and strength.

Corrosion resistance: In general, the corrosion resistance of series 1 pure aluminum is the best, series 5 performs well, followed by series 3 and 6, series 2 and 7 are poor.

Welding performance: Most aluminum alloys are welded without problems, especially some 5 series aluminum alloys, which are designed for welding considerations. Relatively speaking, some 2 series and 7 series aluminum alloys are more difficult to weld.

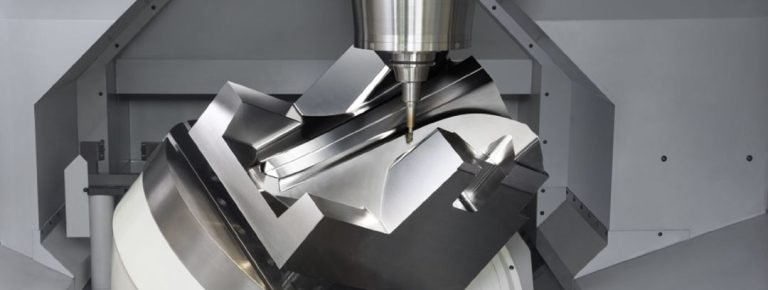

Aluminum alloy machining technology

The mechanical processing technology of aluminum alloy is a series of processes in which aluminum alloy materials are cut, drilled and milling to meet the requirements of part design.

Machining steps of aluminum alloy parts

Select the appropriate aluminum alloy material to ensure that its chemical composition and physical properties meet the design requirements. Commonly used aluminum alloy materials are 6061, 6063, 7075, etc.

Cutting

The aluminum alloy material is cut using appropriate cutting tools (such as cutters, blades) to obtain the desired shape and size. Cutting operations include turning, planing, boring and more.

Drilling

Through drilling, milling machines and other equipment for drilling machining, in order to form the required holes in the aluminum alloy parts. Drilling operation should pay attention to control the machining speed and the use of cutting lubricants to avoid overheating damage to the material.

Milling

Milling machines and other equipment are used for machining to cut the surface of the aluminum alloy material into the desired shape and profile. Milling operations include planar milling, three-dimensional milling and more.

Grinding and polishing

Improve the surface accuracy and finish of aluminum alloy parts through grinding and polishing operations. Grinding and polishing can be done manually and mechanically.

Cleaning and anti-corrosion treatment

The machined aluminum alloy parts are cleaned to remove impurities such as cutting and oil pollution generated during the machining. Subsequently, anti-corrosion treatment is performed to extend the service life of the parts.

Notice

When machining aluminum alloy parts, the following matters need to be paid attention to:

Select the right mechanical equipment and cutting tools to ensure machining quality and efficiency.

Control the machining speed and the use of cutting lubricants to avoid overheating damage to materials.

Pay attention to safe operation and wear personal protective equipment to prevent injury.

Cleaning and anti-corrosion treatment of the finished parts in time to avoid corrosion and quality problems.