Why did the tap break again? Is it a quality problem or a technical problem?

We all encountered tap breakage when machining, why is your tap broken again? We have summarized some of the reasons for you.

1. Bad quality of taps

Material, CNC tool design, heat treatment, machining accuracy, and coating quality all affect the quality of the tap.

For example, the size difference of the tap cross-section is too large or there is no design of the transition fillet resulting in stress concentration, which is prone to fracture at the stress concentration during use.

In addition, tap quenching and heating without preheating, quenching overheating or overcooking, not timely tempering and cleaning too early may lead to tap cracks.

2. Wrong choice of taps

For workpieces with high hardness, high-quality taps should be used, such as cobalt-containing high-speed steel taps, cemented carbide taps, and coated taps.

In addition, different tap designs are used in different work situations. For instance, the size and angle of a tap’s chip removal groove have an impact on chip removal performance.

3. Mismatch between the tap and the material being processed

With the increasing number of new materials and the difficulty of machining, the range of tooling materials is constantly increasing to meet this need. We need to choose the right tap product before tapping.

4. Bottom hole diameter is small

For example, when machining ferrous material M5 x 0.5 threads, you should choose a 4.5mm diameter drill to make the bottom hole. If a 4.2mm drill bit is misused for the bottom hole, it will increase the section that needs to be cut, which will cause the tap to break.

It is recommended to choose the correct diameter of the bottom hole according to the different types and materials, if there is no perfectly matching drill bit available, choose a larger one.

5. Problems with tapping piece materials

Impure material of the tapping piece, partial over-hard spot or porosity will cause the tap to lose balance instantly to break.

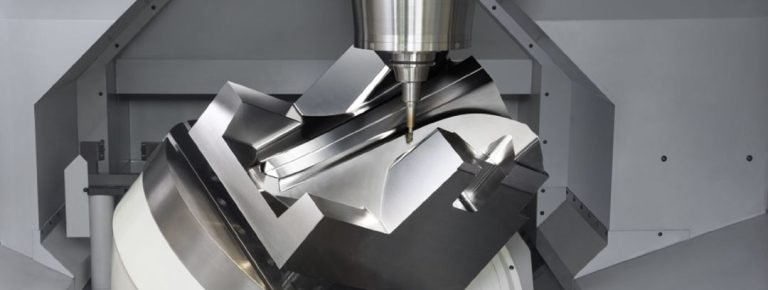

6. The machine tool does not meet the accuracy requirements of the tap

Machine tools and fixtures are also very important, especially for high-quality taps, only high precision machine tools and fixtures can bring out the performance of the taps.

A common problem is insufficient coaxiality, which means that the spindle axis is not concentric with the centerline of the bottom hole, and this can lead to excessive torque, a major cause of tap breakage.

7. Poor quality of cutting fluids and lubricants

If there is a problem with the quality of the cutting fluid and lubricant, the quality of the machined product will be easily burred and affected by other undesirable conditions, and the life of the product will also be greatly reduced.

8. Unreasonable cutting speed and feed rate

When machining problems occur, most operators will reduce cutting speeds and feed rates, so the tap will push less hard and the accuracy will be drastically reduced, which will increase the roughness of the surface of the threads. However, feeding too fast can lead to excessive torque, which also can lead to tap breakage.

Recommended cutting speed: 6-15m/min for general steel; 5-10m/min for quenched and tempered steel or harder steel; 2-7m/min for stainless steel; 8-10m/min for cast iron.

9. Technical problems of operators

All of the above require operator to make a judgment or feedback to the technician. We, CYCO, have professional training for all our employees. Of more than 3,000 staff in our company, more than 10% are technical developers. CYCO, a trustworthy partner you can believe completely!

Summary

The causes of tap breakage are diverse and can be caused by machine tools, fixtures, workpieces, techniques and cutters.

CYCO, a qualified and responsible CNC machining manufacturer, is able to solve all kinds of problems that arise in CNC machining. What is more, we always do our best to avoid problems during CNC machining.

In order to avoid wasting your valuable time, you can choose CYCO as your partner without any hesitation!

Contact us for a worry-free experience now!