CNC machines are one of the most important machines in manufacturing today. There are many different types of CNC machines on the market today with different modes of operation, tools, materials, and the number of axes that can cut simultaneously.

What Is A CNC Machine?

The meaning of CNC derives from Computer Numerical Control. As the name implies, a CNC machine is a computer-controlled device that helps in the manufacturing of parts and products.CNC machines make it easier to create or modify parts from metal, wood, plastic and other materials. There are three main components of an automation system: the drive/motion system, the feedback system, and the command functions. Automated machining system usually makes part manufacturing faster and more accurate than manual machines.

Common Components of CNC Machines

Information input and output devices: disk drives, special information devices, keyboards and computers.

Internet connections: Ethernet, HSSB (high-speed data transmission port), processing LAN, RS 232C port and other networks

Control units for external mechanical axes: change tables, unloading and loading robots, tool magazine drive axes

Feed servo drives and motor units

Spindle motor and drive units

CNC control units

PMC controllers

Machine feedback and position measurement units

Input and output units for machine power cabinet control signals

Basic Definitions of CNC Machines

CNC: Computer Numerical Control – computers and CAM software are used to automate, control and observe machine movements using digital data.

CAM: Computer Aided Machining or Manufacturing – the process of generating toolpaths and NC codes for CNC-operated machines based on data from a 3D computer model (CAD) with the use of different software programs. The combination of the two is often referred to as CAD/CAM.

NC Code: A unique and relatively basic computer language that can be understood and used by CNC machines. It was initially created to enable direct part programming at the keyboard of the machine tool without the need of CAM applications. The most widely used language is G-code, often referred to as ISO code.

Postprocessor: A bridging software component used to convert routes determined by CAM software into precise NC code that can be interpreted by CNC machines. This is because while G-code is considered the industry standard, individual manufacturers are free to change certain components, such as auxiliary functions, making G-code designed for one machine malfunction on another.

Different Types Of CNC Machines Based on the Function

CNC Drilling Machine

Automatic drilling machines that are capable of making precise and complex holes in workpieces. They are equipped with mechanical rotary drills that penetrate the workpiece radially to form cylindrical holes. The design of the drill bit allows chips to fall off the workpiece. Various types of drills are available for different applications, including screw machine drills, peck drills, spotting drills and chucking reamers.

CNC drilling machines control parameters such as spindle speed, feed rate, plunge rate and depth of cut automatically based on instructions provided by the CNC programmer. These machines can process material at higher speeds than traditional manual drilling techniques. In addition, these machines are equipped with intelligent tool changing and positioning technology that helps to increase productivity.

However, CNC drilling machines do have certain limitations to be considered and it may not be suitable for creating deep or large holes. Furthermore, different hole sizes require different drill sizes.

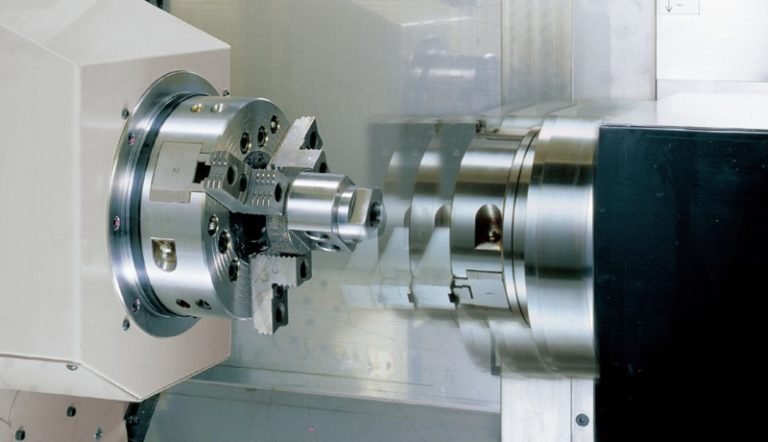

CNC Lathe

A cutting tool is used to remove material from a rotating workpiece to cut to the desired specification. Compared to manual lathes, CNC lathes increase the speed and accuracy of finished product manufacturing. These machines are perfect for a wide variety of processes, including cutting, drilling, turning, sanding, finishing, knurling and more.

However, because of the way this machine makes products, it is usually suitable for creating symmetrical components and may not be suitable for producing customized asymmetrical shapes.

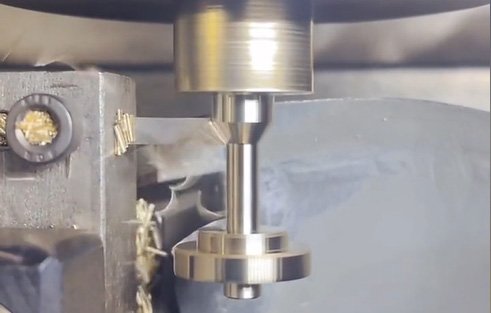

CNC Milling Machine

Utilizing a high-speed rotating multi-point cutting tool to accurately remove material from a workpiece to form a required shape. CNC milling machines are equipped with various types of cutting tools, each of which has a specific purpose. Commonly used cutting tools include drills, face mills, end mills, reamers and taps. These machines are available in both vertical and horizontal configurations, as the milling cutters can work in either a vertical or horizontal orientation.

While CNC milling is a highly efficient technology that enables high-speed precision machining, there are some limitations to be aware of. The first limitation is the size, every CNC milling machine has a maximum capacity for machining the size of the part, which depends on the tool travel distance and the size of the machine enclosure. Secondly, only a skilled operator can operate a CNC milling machine accurately, as errors by the operator can lead to accuracy deviations. Finally, some users consider the initial cost of a CNC milling machine to be a limitation. However advantages such as precision machining compared to other methods make it a worthy investment.

CNC Grinding Machine

Using a grinding wheel to remove material from a workpiece, mainly used for grinding, polishing or finishing. The material used to make grinding wheels can be a ceramic mixture or diamond. However, a CNC grinding machine removes material from the workpiece at a very slow speed, which is why it is primarily used as a finishing machine.

CNC Plasma Cutting Machine

It provides precise and accurate cutting by utilizing a discharge arc similar to a plasma torch. However, the plasma cutting process is only applicable to conductive materials, which limits its use to non-metallic materials such as wood and plastics. In addition, plasma cutting is a process that generates heat to melt the material, and this heat typically affects the surface finish of the cut material, resulting in a heat-affected zone.

CNC Laser Cutting Machine

Cutting hard materials with a highly focused laser beam. CNC laser cutters are typically more expensive than CNC plasma cutters due to the smaller contact point of the laser and less heat diffusion, CNC laser cutters typically offer higher precision and superior surface finish without additional finishing.

CNC laser cutting machines offer material flexibility and the laser intensity can be adjusted to the density and strength of the material for highly efficient cutting. Depending on the type of laser medium used, they can be categorized as gas lasers, liquid lasers and solid state lasers.

One of the limitations of a laser cutting CNC machine is that the maximum thickness of material you can cut with is 2.75 inches. Additionally, due to the potential hazards associated with the laser beam, the operator must have the necessary expertise to control the machine as the laser beam moves across the workpiece.

CNC Water Jet Cutting Machine

As the name implies, high-pressure water jets are utilized to cut various materials, especially excelling at cutting high thickness materials. In some cases, additional abrasives can be utilized to improve cutting efficiency, such as adding garnet to the water.CNC water jet cutting is often used for materials that may melt at high temperatures.

Compared to CNC plasma and CNC laser cutting machines, CNC waterjet cutting machines tend to cut slower, especially when dealing with corners and curved cuts.

CNC Electric Discharge Machining (EDM)

A non-contact machining process that utilizes electric sparks to manipulate and shape materials for machining workpieces of complex design and high precision. The workpiece is located between the top and bottom electrodes and may deflect when subjected to cutting forces.

EDM machines can only work with conductive materials and are not suitable for machining plastics, ceramics, wood or other non-conductive materials. Moreover, EDM machines have relatively slow cutting speeds when machining corners and curves, this is because repeated discharges lead to heavy electrode wear, which results in slower production speeds and higher costs.

3D Printer

Create three-dimensional workpieces by layering materials based on a digital design or model. Unlike the other processes discussed in this article, 3D printing is an additive manufacturing process because it adds material instead of removing it. The material is usually heated and extruded through a nozzle, which is moved precisely to deposit the material onto the work area to form a desired part.

CNC Automatic Tool Changer

Automatic tool changers (ATC) are variants of different types of CNC machines. This feature allows for quick and efficient changing of cutting tools within a CNC machine, it allows for seamless replacement of different types of cutting tools that are damaged or worn out. The ability to automate the tool change process increases production speeds and minimizes machine downtime. CNC machines with automatic tool changers are an important step towards full automation, as changing tools is often a bottleneck in CNC machining, and ATC increases the ability of the machine to use a wider variety of tools.

Types of CNC Machines Based on the Number of Axis

2-Axis CNC Machine

Consisting of two movement axes: X axis (vertical) and Y axis (horizontal), it is considered to be the simplest form of CNC. It is mainly used to perform simple tasks such as creating straight cuts or drilling holes in circuit boards.

3-Axis CNC Machine

The most widely used type of CNC machine, can move in the traditional X and Y axes with an additional Z-axis for depth.

4-Axis CNC Machine

Besides the X, Y and Z axis, a 4-axis machine has a rotary axis, known as the A axis, which enables the cutting tool to make rotational motion along the X axis.

5-Axis CNC Machine

In 5-axis machining, an additional pivoting motion is incorporated, allowing the cutting tool or work table to move along the Y axis. This pivotal and rotational axis is referred to as the C axis. These machines can machine five surfaces of material simultaneously while the work surface remains stationary, which allows them to efficiently manufacture complex and precise parts.

7-Axis CNC Machine

A 7-axis machine has three axis for workpiece rotation, three axis for cutting tool movement, and one axis for arm rotation, called the E axis. The extra motion axis allows for advanced machining operations and complex part designs.

9-Axis CNC Machine

A unique combination of a 5 axis milling machine and a 4 axis lathe. The ability to perform both milling and lathe operations in a single setup enhances the versatility and efficiency of the manufacturing process, allowing 9 axis machines to manufacture parts with internal and external features.

12-Axis CNC Machine

The most complicated one. 12 axis CNC machines are equipped with two cutting heads and can move in all six axis – X, Y, Z, A, B and C. These machines not only increase the speed of production, but also improve accuracy by several degrees.

Types of CNC Machines Based on Moving Trail

Point Control System

In this system, moving parts can only be precisely controlled from one point to another, after the cutting tool has been guided to a predetermined point, the machining process starts around that particular cutting point.

Linear Control System

Apart from precisely arranging the moving parts of a CNC machine tool from one position to another, a linear control system regulates the speed and path of movement between two connected stations.

Contouring Control System

The workpiece moves following the programmed trajectory and speed relative to the cutter under the control of the contouring control system, which also coordinates the motion of multiple feed shafts simultaneously.

Types of CNC Machines Based on Servo System

Open Loop Control System

In an open-loop control system, there is no detection or feedback device. The driving circuit amplifies the power, and the CNC device’s instruction signal is transmitted in a single direction to drive the stepping motor that moves the machine table. One benefit of the open-loop control system is its low pricing, which makes it affordable. On the downside, it has poor accuracy and stability, reducing the work quality.

Semi-Closed Loop Control System

The worktable’s actual displacement is calculated using a semi-closed loop control system’s angular displacement detection device installed directly at the end of the servo motor shaft or ball screw. This control system falls within a moderate price range but offers high precision and stability.

Closed-Loop Control System

In a closed-loop control system, a linear displacement-detecting device is employed, typically mounted on the moving parts or tabletop of the machine tool. The CNC device’s comparator receives the detected actual displacement and compares it to the programmed instruction value. Controlling the stability of a closed-loop control CNC machine is quite difficult. However, this machine guarantees high precision.

How to Choose a Suitable CNC Machine?

Materials To Be Machined

The type of material being machined is an important consideration when selecting a CNC machine. The machine must be strong enough to mill precision parts from carbide. Consider using a precision machine that can maintain the necessary tolerances to machine softer materials such as mild steel.

Availability of Spare Parts

Like any other machine, CNC machines can experience wear and tear or malfunctions over time. To mitigate potential downtime, it’s crucial to select a brand or model that can be efficiently repaired by your specialists and has easily accessible spare parts for replacement. This is important because the availability of spare parts directly affects the amount of time you may have to wait before resuming production.

Power Requirements

These machines require a lot of power and frequently use three-phase power to function optimally. Thus, ensuring the building receives enough power to run the new equipment is crucial. While the existing machines may currently operate within the available power supply, the addition of a new CNC machine might exceed the capacity and lead to power shortages.

Business Types

The nature of your business will determine the available options for you. For instance, if you operate a small CNC machine shop, your needs may be fulfilled by a few CNC routing machines. On the other hand, if you manage a sizable manufacturing company, you will probably require larger and multi-function machines.

Products Requirements

The CNC machine you will need will mostly depend on the work done. A CNC lathe or 3-axis milling machine may be sufficient for simple items. However, as complexity increases, it becomes more cost-effective to have machinery that can fabricate multiple components in a single setup. The most suitable machines for such tasks are five-axis CNC machines.

Conclusion

In this article, different types of CNC machines based on different classifications were discussed, providing explanations of their functions, applications, limitations, how they are used in manufacturing, and how to select the most suitable CNC machine for your needs. Additionally, CNC machines tend to be quite costly, making the initial investment a significant consideration.

Why CYCO

Choosing the ideal CNC machine for your specific requirements can be a daunting task. Fortunately, an alternative solution is to outsource your CNC machining needs to a reliable manufacturer like CYCO.

At CYCO, we have a range of CNC machines, from 3-axis machines to multi-axis machines, to meet all your needs. Our skilled crew is ready to fulfill your product needs, no matter how complex they may be.

Contact us today or request an instant quote online and we’ll provide the best solution for your manufacturing needs.