Waterjet, which is to use water as a knife, first originated in the United States. Favored for it will not change the physical and chemical properties of the material. After continuous improvement in technology, the cutting speed and cutting thickness of the waterjet have been greatly improved by mixing garnet grit and other abrasives in high-pressure water to assist in cutting.

Waterjets have been widely used in many industries such as ceramics, stone, glass and metal.

In China, the maximum pressure of the waterjet has been achieved to 420MPa. Some technologically advanced companies have already completed the 3-axis and 4-axis waterjet, and 5-axis waterjet also tends to be mature.

What is waterjet cutting?

Waterjet cutting is a cold cutting method that uses highly pressurized water to cut all kinds of materials, allowing for one-time cutting of any material with any curve, from foam to metal.

The heat generated during cutting is immediately carried away by the high speed water jet and produces no hazardous substances. There is no heat effect when cutting materials, and it is not necessary or easy to be machined twice after cutting, which is safe, environmentally friendly, faster and more efficient.

The water used for cutting can be pure water or can be mixed with abrasives for greater cutting power.

Waterjet cutting is one of the most advanced machining processes available today, and in addition to cutting, manufacturers use this process to shape and ream materials.

Types of waterjet cutting techniques

Divided by whether sand is added or not: sandless cutting and sandy cutting.

Divided by pressure: high pressure and low pressure, generally 100MPa is the limit. more than 100MPa for high pressure, below 100MPa for low pressure, and more than 200MPa for ultra-high pressure.

…

It is important to be well informed before making a choice.

The technology of pure water cutting

This type of waterjet cutting uses pressure and utilizes the speed of pure water to cut things. Pure water cutting is usually limited to thin materials such as foam, rubber, wood, aluminum foil, cardboard, clothing and food.

The width of the nozzle used for pure water cutting is usually 0.1 mm, but can be as low as 0.08 mm for more complex materials.

Unlike CNC and laser cutting, it is a cold cutting method and does not generate heat.

The technology of abrasive waterjet cutting

Abrasive waterjets use ultra-high pressure water and abrasive particles, such as garnet, to cut materials.

Adding abrasive to pure water creates a more powerful stream, offering more possibilities for cutting harder materials, making abrasive waterjet cutting suitable for ceramics, rocks, metals and plastics.

In addition, the nozzles used for abrasive waterjet cutting have a higher diameter than pure waterjets, with a maximum of 0.375mm.

Some abrasive waterjet machining tools can generate up to 6,000 atmospheres of pressure.

In addition, the cutting technique used here is also non-thermal, which means that no heat is generated.

How to choose the right technology for waterjet machining

The waterjet cutting technique should be determined by the material to be cut. Both techniques are non-thermal, so they can both be used on heat-sensitive materials.

For harder and thicker materials, abrasive waterjets will work best. However, if higher cutting accuracy is required, especially for materials with complex geometries, pure waterjet cutting will be better.

Pure waterjet cutting is favored in the food and pharmaceutical industries because of their strict requirements for foreign material content in their products.

In industry, many waterjet cutters have an abrasive mixing chamber that can be installed on the nozzle of the waterjet cutter.

Process of waterjet cutting

Utilizing the velocity of the super-pressurized water to produce high cutting forces, here’s how it actually works.

First, after pressurizing the water to about 4,000 atmospheres, the water is passed through a high-pressure tube to a nozzle which ejects the water from the waterjet cutter. The nozzles used here must be of a small diameter, usually between 0.1 and 0.4 mm. Due to the small diameter of the orifice, the cutter concentrates the pressure and ejects a narrow jet of water.

As the water leaves the nozzle, the pressure is converted into an extremely high velocity of about 1,000 m/s. This narrow column of overpressurized water is known as a waterjet.

The high force of the waterjet is the reason why industrial waterjet cutting is so precise. The success of the process depends on getting the water under high pressure before it is ejected.

How ultra-high pressure is generated in a waterjet cutter

Before the water can be pressurized, it must be finely filtered and desalinated, usually by reverse osmosis, which is the process of allowing water to lose its impurities as it passes through a semi-permeable membrane.

The operator delivers the filtered water to an ultra-high-pressure pump, which is one of the key components of waterjet cutting. The pressure pump then pressurizes the water to between 3,000 and 4,000 atmospheres. The pressure generated by the pump must be controlled to prevent pressure spikes during the waterjet cutting process.

Once the water is pressurized, a high-pressure tube delivers it to the nozzle and performs the cutting operation.

Because it involves high-pressure waterjet machining, only professionals are allowed to operate.

Components for waterjet cutting

Different waterjet cutters have different components, however, there are five main water cutting components that must be present in any cutter.

They are:

Ultra high pressure pumps

An ultra-high pressure generator, which powers a pressure pump, is responsible for generating the pressurized water needed for cutting. The pump must be able to control the pressure it generates in order to cut the material smoothly.

CNC controller

The software that manages the waterjet cutting machine and ensures that all the sub-programs in the cutting machine function properly.

Conveyor system

Usually the X-Y axis that allows the nozzle to be repositioned according to the desired cutting path of the operator.

Nozzle

A narrow beam of super-pressurized water that is ejected and is referred to as a waterjet. May have an abrasive mixing chamber to allow proper mixing of the abrasive before spraying.

Trap tank

This tank allows the energy of the waterjet to be dissipated after cutting with abrasive-mixed water, which is important for abrasive cutting.

Benefits of waterjet cutting

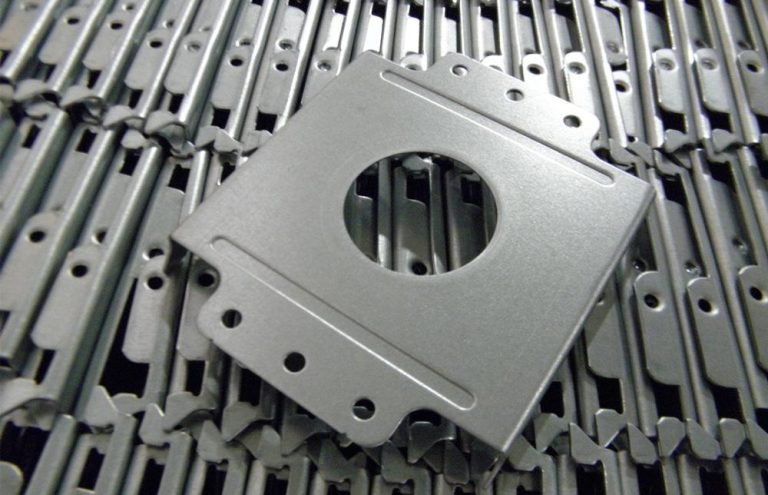

Better edge quality

Smooth, even cut edges can be obtained without burrs, which means no secondary machining is required and simplifies the entire process for manufacturers.

Additionally, you can accurately cut different shapes and even 3D materials, which is often a challenge for many other cutting processes, as the quality of the resulting edges is often substandard in complex materials.

Improve efficiency of operation

In terms of efficiency, few processes in the industry come close to waterjet cutting.

First, the cutting process can be completed quickly because no additional machining is required, which can save valuable time.

Additionally, waterjet technology can cut materials relatively quickly without worrying about the condition of the material.

Suitable for diverse materials

Versatility is one of the biggest selling points of waterjet technology, as there are fewer cutting processes suited to different materials of varying hardness.

With waterjet cutting, you can cut materials as thick as 200 mm or as thin as paper.

What’s more, you won’t have to worry about warping during the cutting process as long as you use the right waterjet cutting technique and handle the process professionally.

No need to change the cutter

When working with a pure waterjet cutter, if something very thick needs to be cut, it is only necessary to install a mixing chamber on the nozzle to get an abrasive cutting without the need to spend money on an additional cutter.

Furthermore, another cutting technique is not required for more minor thickness variations as the feed speed of the cutter can be modified to meet the various speed requirements needed to cut the material.

No heat effects

Before the advent of waterjet cutting processes, thermal distortion was one of the most significant problems in the cutting industry. The reason for this is that many industrial cutting processes generate heat during operation, which can lead to warping or distortion of the material after a long period of time.

Waterjet cutting is a non-thermal process that does not generate heat, making it suitable for heat-sensitive materials.

In addition to potentially damaging the material, the heat can also be a health hazard to the operator.

Protect the environment

Waterjet technology is safe for operators by eliminating the risk of hazards during and after the cutting process by not adding chemicals and not generating dust during the cutting process.

Applications of waterjet cutting

For cutting

The waterjet cutter can cut all kinds of materials with different hardness including foam, plastic, aluminum foil, plastic, rubber, stone, ceramic, glass, leather products, metal and more.

Before waterjet cutting begins, it is important to ensure that the technique is appropriate for the material to be cut. For example, the higher pressure in an abrasive cutter can deform soft materials such as foam.

Product Manufacturing

Waterjet cutting is often required by the aerospace, transportation, defense, construction, and automotive industries because of the high quality they demand, and these industries often require precision cutting of material components.

For cleaning

It can be used for descaling steel plates, deburring parts, grinding and removing crystallization from pipes.

…

Waterjet machining is one of the faster growing machining processes.

Many industries have adopted this process because of its ability to cut all kinds of materials with high quality. Its environmental friendliness and ability to not deform the material with heat during the cutting process have made it the dominant cutting technology.

CYCO – satisfy all your CNC machining requirements

Due to the high pressures generated during machining, industrial waterjet cutting must be handled carefully by experts.

CYCO, with over twenty years of CNC machining experience, we have experienced professionals to handle all of your waterjet machining needs for CNC machined parts.

Contact us for a free and instant quote!

Work with us for a worry-free experience!