Machining accuracy is the actual size, shape and position of the machined part surface in accordance with the drawing requirements. The value of deviation between actual and ideal geometric parameters of the part is called machining error.

Concept of machining accuracy

Machining accuracy and machining error are both terms for evaluating the geometric parameters of a machined surface.

Machining accuracy is measured in terms of tolerance grades. The smaller the grade value, the higher the accuracy. Machining error is expressed as a numerical value. The larger the value, the greater the error. High machining accuracy means low machining error and vice versa.

Tolerance grades range from IT01, IT0, IT1… to IT18, 20 in total. IT01 means that the part is machined with the highest precision while IT18 means the lowest precision. In general, IT7 and IT8 are the mid-level.

The actual parameters obtained by any processing method will not be absolutely accurate. From the function of the part, as long as the machining error is within the tolerance range required by the part drawing, the machining accuracy is considered to be guaranteed.

The quality of the machine depends on the machining quality of the parts and the assembly quality of the machine. The machining quality of the parts includes the accuracy of the parts machining and the surface quality.

Related contents of machining accuracy

1. Dimensional accuracy

The extent to which the actual dimension of a machined part conforms to the center of the tolerance zone of the size.

2. Shape accuracy

The level of match between the actual surface geometries of a machined part and the desired one.

3. Positional accuracy

The actual difference in positional accuracy between the relevant surfaces of a machined part.

4. Mutual relations

When designing machine parts and setting the machining accuracy of the parts, it should be noted that the shape error should be controlled within the positional tolerance, and the positional error should be smaller than the dimensional tolerance. That is to say, precision parts or important surfaces of parts, their shape accuracy requirements should be higher than the positional accuracy requirements, and the positional accuracy requirements should be higher than the dimensional accuracy requirements.

Measurement methods for machining accuracy

Machining accuracy is measured in different ways depending on the contents and the requirements. There are generally several types of methods:

1. Direct and indirect measurements

Direct measurement: use calipers and comparators to measure directly.

Indirect measurement: measure the relevant parameters and then calculates them to obtain the measured dimensions.

Obviously, direct measurement is more intuitive and indirect measurement is more cumbersome. Usually when the measured size with direct measurement can not meet the accuracy requirements, it is necessary to use indirect measurement.

2. Absolute and relative measurements

Absolutemeasurement: the reading value directly indicates the size of the measured dimension, such as measured with vernier calipers.

Relative measurement: the reading value indicates only the deviation of the measured dimension from the standardized quantity. For example, to measure the diameter of a axis with a comparator, it is necessary to adjust the zero position of the instrument with a gauge block, and then measure it. The measured value is the difference between the diameter of the measured axis and the size of the gauge block, which is a relative measurement.

Generally, relative measurement is more accurate, but more troublesome.

3. Contact and non-contact measurements

Contact measurement: the measuring head is contacted with the surface to be measured and there is a mechanically acting measuring force existing. For example, measuring parts with a micrometer.

Non-contact measurement: The measuring head does not contact the surface of the measured part, which avoids the influence of the measuring force on the results. For example, using projection methods, light wave interference measurements and more.

4. Analytical and composite measurements

Analytical measurement: each parameter of the measured part is measured individually.

Composite measurement: a composite indicator that measures the relevant parameters of a part. For example, when measuring threads with a tool microscope, you can separately measure the actual pitch diameter of the threads, errors in half of thread angle, cumulative error in pitch and more.

Composite measurement is more efficient and more reliable in ensuring the interchangeability of parts, and is commonly used in the inspection of completed parts. Analytical measurement can determine the error of each parameter separately and is generally used for process analysis, process inspection and measurement of the specified parameters.

5. Active and passive measurements

Active measurement: workpieces are measured during machining, and the results are used directly to control the machining process of the part and prevent the production of waste products in time.

Passive measurement: measurement taken after the workpiece has been machined. This measurement can only determine whether the machined part is qualified or not, and is only used to find and reject waste products.

6. Static and dynamic measurements

Static measurement: relatively static, such as measuring a diameter with a micrometer.

Dynamic measurement: The measured surface and the measuring head simulate relative motion in the working state, which reflects the condition of the part close to the state of use, and is the direction of development of measurement technology.

Adjustment methods for machining accuracy

1. Reduce errors in the transmission chain

The fewer the number of transmission parts and the shorter the transmission chain, the higher the transmission accuracy.

Reducing speed transmission is an important principle to ensure transmission accuracy. The closer to the end, the smaller the transmission ratio should be.

The accuracy of the end piece should be higher than the other transmission pieces.

2. Decrease tool wear

The cutter must be resharpened before it reaches a stage of acute wear in terms of cutter size.

3. Minimize force deformation of the process system

Improve the stiffness of the system, especially the weak points in the process system.

Reduce the load and its changes.

Prevent localized low stiffness.

Reasonable selection of the structure and cross-sectional shape of both the basic parts and the support parts.

4. Adjust the process system

Pre-adjust the relative positions of the machine, fixture, workpiece and cutter to obtain the required dimensions. This method is highly productive and can be used for mass production in large quantities.

5. Less machine tool error

Choose high precision bearings.

Eliminate the bearing clearance.

Increase bearing stiffness.

6. Reduce thermal deformation of process systems

Use a smaller cutting condition.

Separate the heat source from the machine as much as possible to minimize thermal deformation of the machine.

For heat sources that cannot be separated, improve their friction characteristics to reduce heat generation or use heat-insulating materials.

Adopt forced air cooling, water cooling and other heat dissipation measures.

Adopt reasonable machine component structure and assembly reference.

Reasons affecting machining accuracy

1. Errors in machine tools

Refers to manufacturing errors, mounting errors and wear of the machine tool. It mainly includes the guiding error of the machine tool guideway, the rotary error of the machine tool spindle, and the transmission error of the machine tool transmission chain.

2. Errors in processing principles

Refers to the error resulting from machining using an approximate cutter edge profile or an approximate transmission relationship. It is mostly used in the machining of threads, gears and complex surfaces.

3. Errors in adjustments

Refers to errors due to inaccurate adjustments.

4. Residual stresses inside the workpiece

Generation of residual stresses:

From the embryo manufacturing process and the heat treatment process.

From the cutting process.

5. Impact of the processing environment

There are often many small metal chips at the machining site, which will affect the machining accuracy of the parts if they are present on the positioning surface of the parts or in the location of the positioning holes. For high-precision machining, metal chips that are too small to be seen by the eye can affect accuracy, which requires excellent handling by the operator.

6. Manufacturing errors and wear of fixtures

Manufacturing errors in positioning elements, guiding elements of cutters, fixtures, etc.

The relative dimensional error of the working surfaces of various components after fixture assembly.

Wear on the working surface of the fixture during use.

7. Manufacturing errors and wear of cutters

The effect on machining accuracy depends on the type of cutter. For example, normal cutters (such as turning tools, boring tools, and milling tools), the manufacturing accuracy of which has no direct effect on the machining accuracy, but the tools are prone to wear.

8. Force deformation of the process system

The process system will be deformed under the action of cutting force, clamping force, gravity and inertia force, which will destroy the mutual positional relationship of the components of the process system that has been adjusted, leading to the generation of machining errors and affecting the stability of the machining process.

9. Thermal deformation of the process system

During the machining process, the process system is deformed by heat due to internal heat sources (cutting heat, friction heat) or external heat sources ( environmental temperature, thermal radiation), which affects the machining accuracy.

Summary

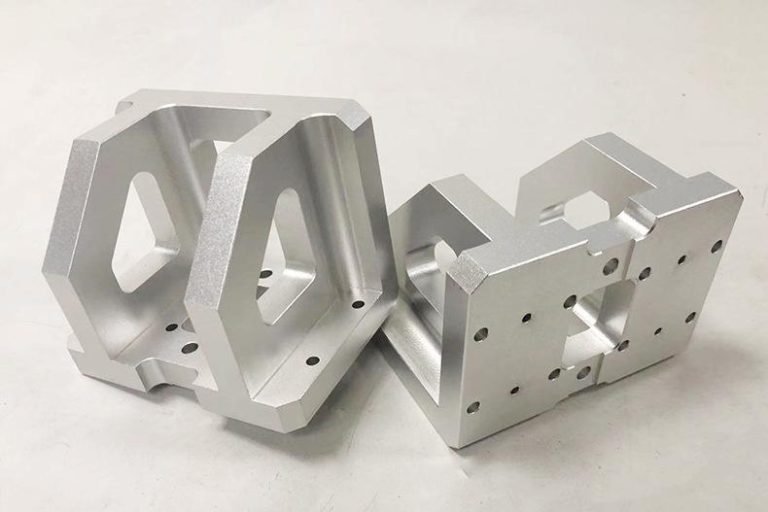

In CNC machining, precision is the primary prerequisite. This is because in the machining process, precision not only affects the productivity of the product and the process, high-precision CNC machining can also effectively reduce the production of unqualified products and reduce production costs.

With over twenty years of experience in precision CNC machining, CYCO is a trustworthy partner. We have advanced technology and equipment and professional staff to provide a variety of CNC machining services.

In order to avoid wasting your valuable time, you can choose CYCO as your partner without any hesitation!

Contact us for a worry-free experience now!