Machining services in China have become popular due to the country’s manufacturing capabilities, cost advantages, and vast industrial infrastructure. However, like any outsourcing option, using machining services in China comes with its own set of advantages and disadvantages. Let’s explore them:

Advantages of Machining Services in China:

1. Cost-Effective: China’s lower labor costs and economies of scale can often result in significant cost savings compared to machining services in developed countries.

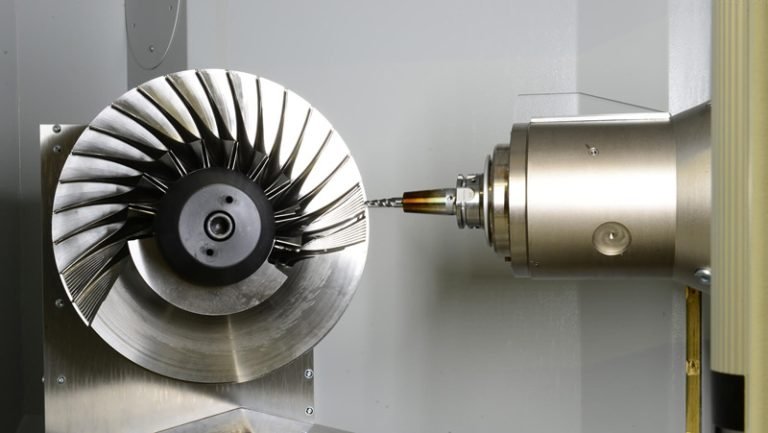

2. Skilled Workforce: China has a large pool of skilled workers and engineers specialized in various machining techniques, allowing for a wide range of machining capabilities.

3. Technological Advancements: China has made considerable advancements in machining technologies and equipment, enabling high-quality and precise machining services.

4. Manufacturing Capacity: The country has a vast manufacturing capacity, which means that even large-volume production runs can be handled efficiently.

5. Wide Range of Materials: Chinese machining services can work with a diverse range of materials, including metals, plastics, and composites, catering to various industry needs.

6. Rapid Turnaround: China’s machining industry is well-known for its ability to deliver projects with short lead times, especially for simple to moderately complex parts.

7. Customization and Prototyping: Chinese machining services are often willing to work on custom projects and prototype development, offering flexibility to clients.

Disadvantages of Machining Services in China:

1. Quality Control: Ensuring consistent quality can be challenging in some cases, as not all Chinese machining providers may adhere to the same rigorous quality standards found in Western countries.

2. Language and Communication: Language barriers can sometimes lead to misunderstandings or miscommunications between clients and suppliers, potentially impacting project timelines and outcomes.

3. Intellectual Property Concerns: There have been instances of intellectual property theft or counterfeiting in China. Companies must take measures to protect their proprietary designs and technologies when outsourcing machining services.

4. Distant Supply Chain: Shipping products from China to other parts of the world can lead to longer transit times, which may affect the overall production timeline and logistics costs.

5. Cultural Differences: Understanding and navigating cultural differences can be challenging, particularly in negotiations and dispute resolution.

6. Compliance and Regulations: Some Chinese machining suppliers may not adhere to the same environmental and labor regulations as in Western countries, potentially raising concerns for companies focused on sustainable practices.

7. Quality Variability: The quality of machining services can vary significantly between different suppliers in China, making it essential to conduct thorough due diligence before selecting a partner.

Utilizing machining services in China can offer cost advantages, access to skilled labor, and a vast manufacturing capacity. However, companies must carefully evaluate potential suppliers, establish clear communication channels, and implement robust quality control measures to maximize the benefits while mitigating potential risks and challenges.