A compressor is a mechanical device designed to compress gases to higher pressure levels and is widely used in industrial, manufacturing and other applications where high pressure gases are required.

Introduction to Compressors

A mechanical device that lifts low pressure gases into high pressure gases and is the heart of a refrigeration system. It inhales low temperature and low pressure refrigerant gas from the suction pipe, compresses it through the piston driven by the motor operation, and then discharges the high temperature and high pressure refrigerant gas to the discharge pipe, providing power for the refrigeration cycle.

Main Uses of Compressor

Refrigeration and A/C

The key component of the refrigeration cycle, it compresses the refrigerant from a low-pressure gas to a high-pressure gas, and then releases heat through the condenser. This application is widely found in air conditioning systems, refrigeration equipment, refrigerators and cold stores.

Pneumatic Tools and Equipment

Pneumatic tools (like drills and sanders) and equipment (such as actuators on automated production lines) often rely on compressed air as a power source.

Oil and Gas

Gas compressors are used to compress natural gas during extraction and processing, to compress gases and liquids in refining processes, and to increase pipeline delivery pressure.

Industrial Gas Production

Used for the production of high purity gases such as oxygen, nitrogen and hydrogen for a variety of industrial and laboratory needs.

Medical

In medical equipment, such as ventilators and anesthesia machines, compressors are used to supply purified, medical-grade compressed air.

Mining

To provide ventilation for underground workings and at the same time to power some mining machinery.

Environmental Protection

Air pollution control equipment, such as exhaust gas treatment facilities, may use compressors to drive certain processes.

Food and Beverage

Used for gas injection, packaging, preservation, and more.

…

With such a wide range of uses, how do you choose the right compressor for your needs? In the next section, we’ll introduce some commonly used compressors, including how they work, their advantages and disadvantages.

Main Types of Compressors

Reciprocating Compressors

Operating Principle

One or more pistons are used to make reciprocating movements in the cylinder. When the piston moves towards the bottom of the cylinder, the gas is drawn in, and when the piston moves towards the top of the cylinder, the gas is compressed.

Working Process

- Suction: The piston moves downward, negative pressure is formed inside the cylinder, and external air is sucked in through the inlet valve.

- Compression: The piston moves upward and the gas is compressed, generating high pressure.

- Exhaust: After the compression is completed, the piston moves downward again and the compressed gas is pushed out through the exhaust valve.

Advantages

- Relatively simple construction, easy to manufacture and maintain. Particularly suitable for small to medium sized applications.

- Can provide high efficiency, but efficiency is also affected by compression ratio, operating conditions and design.

- Sensitive to load fluctuations and suitable for applications with large load fluctuations.

- Reciprocating compressors can be single or multi-stage, depending on the desired final compression ratio. Multi-stage reciprocating compressors are typically used in applications requiring high pressures.

Disadvantages

- Due to the reciprocating motion of the piston, reciprocating compressors generate relatively high vibration and noise levels, which may require additional vibration isolation and noise reduction.

- Long running times and frequent starts or stops can lead to wear and tear of reciprocating compressor components, requiring more frequent maintenance.

- At high flow rates and pressures, reciprocating compressors may have a relatively low energy efficiency.

- Reciprocating compressors may have a limited flow range compared to some other types of compressors.

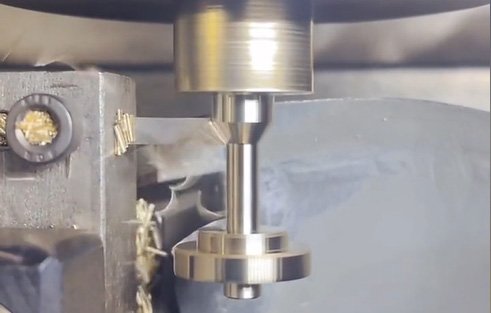

Screw Compressors

Operating Principle

Consisting of two or more screws, their rotary motion causes the gas to be gradually compressed between the screws. Unlike reciprocating compressors, screw compressors achieve continuous compression and provide a relatively constant output stream.

Working Process

- Suction: The gas enters the screw cavity of the screw compressor through the suction port.

- Screw Movement: The two screws rotate in a helical pattern, gradually reducing the volume of the gas to achieve gas compression.

- Exhaust: The compressed gas is discharged through the exhaust port and supplied to the system or equipment.

Advantages

- Generally have a high compression efficiency, especially in applications with high flow rates and pressures.

- Due to their continuous compression characteristics, screw compressors can be operated continuously and are suitable for applications requiring a constant gas supply.

- It is suitable for widely varying working conditions and has a good adaptability to flow and pressure fluctuations.

- Compared with some other types of compressors, screw compressors usually have a more compact design.

- Generally produce lower vibration and noise, providing a smoother and quieter operating environment.

Disadvantages

- High manufacturing accuracy is required and the initial investment is high.

- Efficiency may be compromised in the event of large load fluctuations.

- Screw compressors may have higher maintenance costs compared to other types of compressors. Regular maintenance and overhaul is essential to keep them running efficiently.

- Not well suited for handling high temperature gases as the high temperatures may cause damage to the screws and sealing materials. In addition, screw compressors require clean air to operate properly, so additional air handling equipment may be required to remove dust and other contaminants.

- Since screw compressors require lubricating oil for their operation, regular replacement and maintenance of the lubrication system is necessary.

Centrifugal Compressors

Operating Principle

A rotating impeller is utilized to apply kinetic energy to the gas entering the machine, causing the gas velocity to increase, and then the kinetic energy of the gas is converted into pressure energy by a diffuser. Usually, the centrifugal element in a compressor is a rotating drum or disk.

Working Process

- Suction: The gas enters the centrifugal compressor through the suction port and enters the center area of the centrifugal element.

- Centrifugal Movement: The rotating movement of the centrifugal element pushes the gas towards the outer edge of the element, creating a high speed centrifugal movement.

- Compression: The high speed rotation of the centrifugal element pushes the gas towards the outer edge of the centrifugal element, generating high pressure.

- Exhaust: The compressed gas is discharged through the exhaust port and supplied to the system or equipment.

Advantages

- Centrifugal compressors are relatively more efficient when handling large gas flows.

- Compared to some other types of compressors, centrifugal compressors usually have a high adiabatic efficiency.

- Due to the relatively low pulsations generated, centrifugal compressors are suitable for applications requiring continuous operation.

- For their design, centrifugal compressors typically produce low vibration and noise.

Disadvantages

- They may suffer when handling gases with liquid components. This can lead to liquid entering the compressor, causing damage or reduced performance.

- Sensitive to the temperature of the medium, especially for high-temperature gases. High temperatures may lead to degradation of the performance of the lubricant as well as thermal stress on the components.

- Efficiency may be low under partial load conditions. The operating efficiency of the compressor may be reduced at low loads.

- Because of the relatively complex design of centrifugal compressors, their manufacture and maintenance require a high degree of precision and expertise.

Turbocompressors

Operating Principle

Gas is compressed using the rotation of a turbine, which consists of one or more rotating turbines, usually with static and dynamic parts. The gas is compressed by the rotation of these turbines.

Working Process

- Suction: The gas enters the turbocompressor through the suction port and enters the space between the turbine and the static turbine.

- Turbine Movement: The turbine of the turbocompressor starts to rotate and the gas is pushed towards the outer edges of the turbine by the centrifugal force of the turbine, creating a high speed turbine movement.

- Compression: The high speed turbine rotation compresses the gas, increasing the pressure and temperature of the gas.

- Exhaust: The compressed gas is discharged through the exhaust port and supplied to the system or equipment.

Advantages

- Often have high adiabatic efficiency, especially for applications requiring high pressure and high flow rates.

- Suitable for large-scale systems, capable of handling large quantities of gas.

- Due to the nature of the turbine motion, the output of a turbo compressor is relatively non-pulsating, making it suitable for applications where smoothness of gas flow is important.

- Adaptable to widely varying load conditions and able to cope with load fluctuations to a certain extent.

Disadvantages

- Sensitive to the temperature of the gas, especially in the case of high temperature gases. High temperatures may cause damage to the turbine and other components.

- High requirements on the quality and humidity of the inlet gas, which may lead to problems with the compressor if the gas contains impurities or if the humidity is too high.

- Due to the relatively complex design of turbo compressors, their manufacture and maintenance require a high degree of precision and expertise.

Rolling Compressors

Operating Principle

Contains two or more rolling elements, often called rotating rollers and fixed rollers. These elements roll against each other in a rotary motion to achieve gas compression.

Working Process

- Suction: The gas enters the rolling compressor through the suction port and enters the space between the rotating and stationary rollers.

- Rolling Movement: The rotating rollers and fixed rollers roll against each other in a rotating manner, gradually compressing the gas.

- Exhaust: The compressed gas is discharged through the exhaust port and supplied to the system or equipment.

Advantages

- Due to the rolling motion, it usually produces lower vibration and noise, providing a smoother and quieter operating environment.

- High insulation efficiency enables effective gas compression at relatively low power levels.

- Due to the simplicity of the rolling mechanism, rolling compressors tend to be highly reliable and require less maintenance.

- Low power start-up, which helps minimize the shock to the electrical system during start-up.

Disadvantages

- Suitable for lower power applications and may be less suitable for industrial grade applications with high power requirements.

- Due to their design characteristics, rolling compressors are generally not suitable for high flow applications where large volumes of gas need to be handled.

Tips for Selecting a Compressor

Evaluating Gas Demand

Determine the required gas volume (air output per unit of time) and pressure requirements.

Consider future growth requirements to ensure that the selected compressor will be able to meet the needs of production expansion.

Match the Electrical System

Select compressors based on voltage and power requirements to ensure compatibility with existing electrical infrastructure.

Think about the impact of starting currents on the grid, especially for large compressors.

Consider Energy Savings and Efficiency

Select compressors with high Energy Efficiency Ratio (EER) or Integrated Part Load Value (IPLV) to reduce running costs.

Consider using variable frequency drive (VFD) technology, which can maintain efficient operation at varying loads.

Installation and Maintenance

Choose a compressor that is easy to install and maintain, which reduces the total cost of ownership over the life cycle.

Ensure that there is enough space for repairs and service, and consider the availability of spare parts and consumables.

Environmental Compliance

Check that the compressor complies with local environmental regulations, such as noise limits and emission standards.

Summary

In summary, compressors play a vital role in many industries. The proper selection and use of compressors is important for increasing productivity and reducing costs. We hope that the information provided in this article will help you to better understand compressors and provide a valuable reference for your selection.

If you still have questions about compressors, feel free to consult a specialized machining manufacturer like CYCO. With more than twenty years of experience in machining and manufacturing, we can suggest effective solutions to your problems.