Stainless steel, one of many types of steel, is one of the metals used for CNC machining because of its incredible versatility. It is known for its strength and durability even in wet or corrosive environments, which makes it a very popular metal.

It can be used in various industries, including automotive, medical, and aerospace. However, not all types of stainless steel are easy to machine, and CNC machining stainless steel may come with some challenges.

This article explains many benefits of using stainless steel in your products, as well as the challenges of using it. We will also outline some of the best stainless steel alloys for CNC machined parts.

Types of Stainless Steel

Austenitic Stainless Steels

Contains at least 16% chromium and 6% nickel (base grade 304 is 18% chromium, 8% nickel). It is widely used in chemical plants and food processing equipment because it will not easily corrode, rust or stain after contact with water.

Ferritic Stainless Steels

Contains chromium (usually between 11% and 27%) and little or no nickel. They are not as corrosion resistant as the austenitic grades, but are more iron-like and exhibit better mechanical properties at high temperatures.

Martensitic Stainless Steels

Contains chromium (14% to 18%) and a moderate amount of carbon (usually between 0.2% and 1.2%). They can be hardened and tempered like carbon steels.

Duplex Stainless Steels

Contains chromium (18% to 28%) and nickel (3.5% to 5.5%). They have better corrosion resistance than austenitic grades and are less likely to embrittle than martensitic grades due to their lower carbon content.

Precipitation Hardening Stainless Steels

Contains chromium (12-16%) and nickel (3-9%) as well as aluminum, copper and titanium to form precipitates. They can be heat treated, are very strong and highly ductile.

Benefits of CNC Machining Stainless Steel

Stainless steel is an excellent CNC machining material choice for creating rugged and durable items. Here are some of the benefits of choosing stainless steel for CNC machining projects.

High Tensile Strength

The tension required to stretch a material to its breaking point is called tensile strength.

Stainless steel has a higher tensile strength than mild steel, brass and different types of aluminum alloys. This is an important quality for the lifetime of a product, especially for parts that are subjected to a lot of bending and rolling.

Low Temperature Resistance

Some grades of stainless steel maintain their stability at a wide range of temperatures. For example, austenitic steels exhibit excellent toughness and higher tensile strength even below 0 ℃. But it should be noted that not all stainless steel grades have this property.

Corrosion Resistance

Stainless steel is highly resistant to corrosion and can withstand water damage and rust, including extreme temperatures and pressures. This corrosion resistance makes stainless steel ideal for a wide range of outdoor and indoor applications. This property of stainless steel is due to its chromium content, which forms a thin layer to protect the steel when in contact with oxygen.

Challenges of CNC Machining Stainless Steel

Overheating

Unlike many other types of metals, stainless steel is a poor conductor of heat. But using stainless steel can cause it to heat up quickly, which can damage the stainless steel itself as well as the tools and CNC machines used in the process.

Difficulty with Surface Finish

Choosing the right surface finish for stainless steel CNC machined parts can be quite difficult. This is because unlike other metals, surface finish of stainless steel not only affects its aesthetics, but also other qualities such as corrosion resistance, electrical properties, impact resistance and weldability.

Easily Hardened

Austenitic stainless steels are particularly easy to harden during machining, which can make them harder and increase tool wear. If the machinist is unfamiliar with stainless steel machining, this may negatively affect the quality of the finished product.

Tips For CNC Machining Stainless Steel

While there are some challenges when CNC machining stainless steel, there are ways to prevent this problem and ensure a smooth process.

Here are some tips for CNC machining stainless steel:

Choose End Mills and Drills with High-quality

It’s best to use tools made from high-quality materials, such as molybdenum or tungsten high-speed steel, which can withstand the stresses created when cutting stainless steel and minimize wear at the same time. The tools also improve surface finish. In addition, avoid using tools that are easily worn out, as this can reduce machining speeds while increasing production costs.

Control of Generated Heat

It is one of the reasons why stainless steel CNC machining fails. So it is best to keep the cutting speed low and use coolant to control the heat. Furthermore, it is generally recommended to stop machining when the material is overheated.

Make Sure the Workpiece is Not Deformed

There are many factors that can distort a workpiece, including speed, feed rate and cutting tools. Using worn cutting tools can increase tool deflection, which can lead to out-of-tolerance and distorted parts. That’s why it’s important to use the recommended speeds and feed rates when machining stainless steel.

Best Stainless Steel Alloys for CNC Machining

Of the 10 steel alloys that are excellent choices for manufacturing machined parts, four are stainless steel:

| Type | Description | Advantages | Disadvantages | Applications | |

| SS 303 | Free Machining Stainless Steel | One of the most readily available and highly machinable of all austenitic grades of stainless steel. | Excellent machinability, good corrosion resistance, moderate cost. | Cannot be hardened by heat treatment. Not suitable for marine applications. | Electronic hardware, nuts and bolts, screws, aircraft fittings, bushings. |

| SS 416 | Free Machining Stainless Steel | Offers superior machinability to any other stainless steel. | Outstanding machinability, moderate corrosion resistance, good strength. | Not suitable for chlorine or marine environments. Poor weldability and limited availability. | Valves, pump shafts, gears, nuts, bolts. |

| SS 304 | Stainless Steel | One of the most common stainless steels alloys available with good weldability. | Good machinability, weldability, and cost. Excellent corrosion resistance. | Susceptible to stress corrosion cracking in some applications above 60°C. Some other stainless steel alloys offer better resistance to pitting and crevice corrosion. | Food handling, utensils, automotive parts, architectural applications, heat exchangers, screws. |

| SS Grade 17-4 | PH Stainless Steel | It is a grade of martensitic precipitation-hardened stainless steel, containing up to 30% chromium. | Very high toughness, strength, and corrosion resistance. | Requires efficient and careful heat treatment. | Nuclear reactors, aircraft turbines, oil and gas applications. |

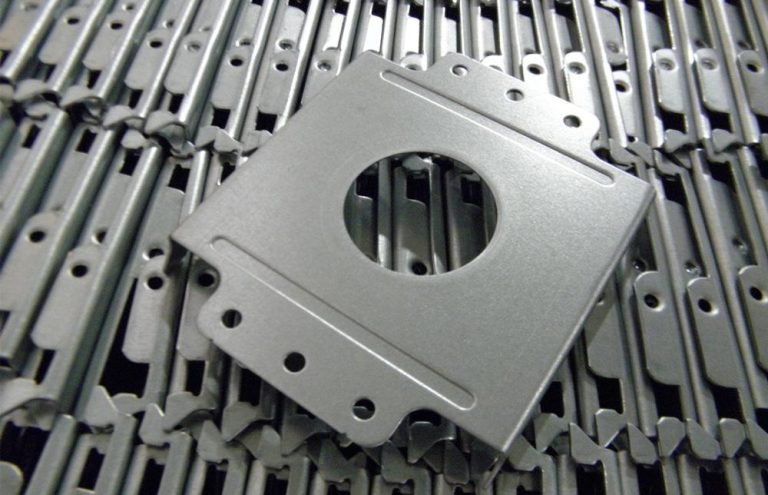

Finish Options for Stainless Steel CNC Machined Parts

Media Blasting

A technique used to clean, strip, etch or smooth stainless steel surfaces. This process removes any contaminants and creates a smoother surface than before. Compared to other cleaning methods, such as grinding, the benefits of media blasting include cost-effectiveness and efficiency.

Grinding

A technique used to smooth the rough surface of stainless steel. It uses an abrasive material (such as sandpaper) to gradually remove small amounts of stainless steel from the surface, resulting in a smoother surface. Polishing can be done by hand or with the use of power tools.

Powder Coating

The process of applying dry powder to a stainless steel surface and then heating it to cure. The uniform powder adheres to the metal surface as it is heated and melted. The process offers many benefits such as improved durability, appearance, corrosion resistance, weathering and abrasion resistance.

Conclusion

In summary, while there are some challenges with the use of stainless steel, the benefits are usually worth it. Stainless steel offers a variety of benefits to manufacturers. Its main benefits are corrosion resistance, the ability to withstand harsh environments, and a longer service life than many metals.

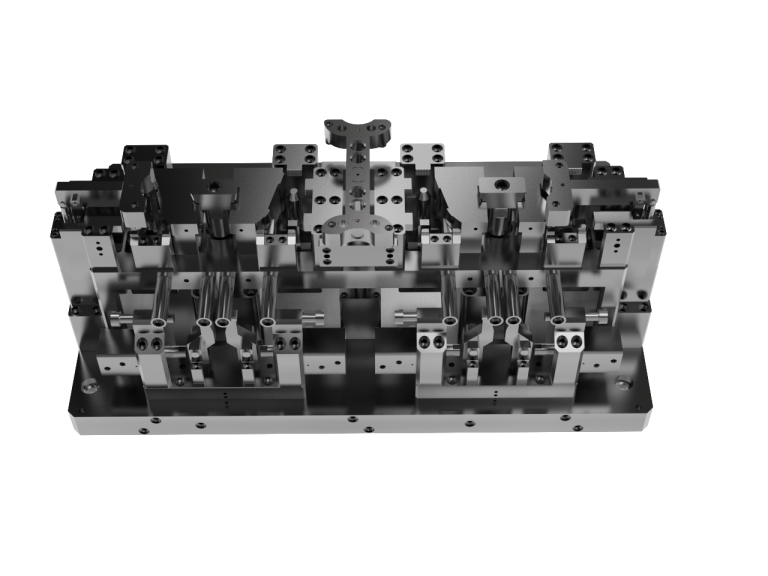

Why CYCO

With our specialized large-scale CNC machine shop and skilled engineers, we can customize stainless steel parts to meet specific needs of our clients.

In addition, we offer a full CNC machining service, which means we can produce parts with the highest levels of precision and accuracy.

If you’re looking for a stainless steel CNC machining service provider, then we’re the right choice for you.

Contact us for an instant quote and work with us for a worry-free experience!