What is Reamer

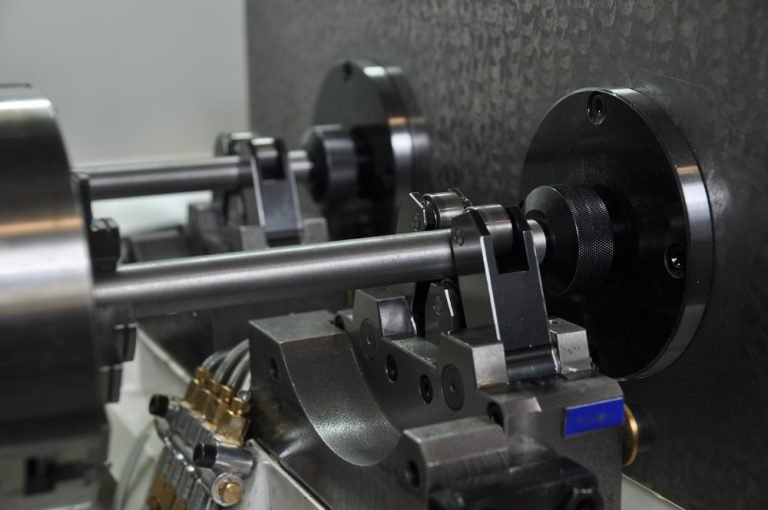

Reaming is a basic machining process used by machinists to achieve accurate dimensions and finishes for drilled or bored holes. A reamer is a tool used to enlarge or finish pre-drilled or bored holes to provide a good finish and precise dimensions that are difficult to achieve by drilling alone.

Reamers are multi-toothed tools with complex geometries that allow them to effectively remove material while providing a smooth surface finish. This makes reaming an indispensable process for achieving high quality results in industries such as aerospace, automotive and medical manufacturing, where precision and accuracy are critical.

Elements of Reamer

Reamers create highly accurate and uniform holes by removing a small amount of material from the inside walls of the hole. Reamers are complex in design and include multiple components that play a critical role in the accuracy of the holes they produce.

Axis:

like milling cutters, reamers are axisymmetric. The central axis is an important geometric feature because it can be used to define tool offset and characterize motion errors.

- Body: the part of the reamer starting from its entry end to the shank.

- Shank: the part of the tool used to hold and drive it.

- Flute diameter: the maximum cutting diameter of the reamer bit, which defines the final hole size.

- Flute length: the length of the part with the cutting edge. It defines the cutting load and distribution of the tool.

- Overall length: the total length of the tool, which limits the depth of the hole in which the reamer will be used.

- Back taper: the reduction in diameter per unit length from the entrance end to the other end. This taper makes chip evacuation and load concentration on the front side of the tool easier.

Types of Reamer

Carbide Reamer

Cemented carbide materials, such as tungsten carbide, titanium carbide and tantalum carbide, are one of the hardest materials that can be manufactured on a large scale. Unfortunately, carbide reamers are very brittle, so they must be mounted and used with great care to avoid cracking and chipping. Carbide tips can be mounted on reamers made from cermet or high speed steel (HSS), or the entire tool can be made from a single piece of carbide. However, this design depends on the size of the reamer, for example, small machines are ground from an entire carbide shaft.

Taper Pin Reamer

With tapered flutes (cutting surfaces) for precise fitting of taper pins. These cutters have straight grooves, slightly twisted ( spiral ) grooves, or heavily twisted ( helical ) grooves. They are categorized according to their tip diameter, root diameter and length instead of nominal diameter and angle. Taper pin reamers are equipped with a series of parallel and machine taper shanks to fit various collets, chucks and taper locks. They also usually have a square tip on the shank, allowing them to be fitted with a manual tapping wrench and used manually. Taper pin reamers are usually made from high speed steel (HSS), but carbide tips are also available.

Hand Reamer

A precision grinding tool for hand reaming, used to expand pre-drilled holes to precise diameters by hand instead of using a machine tool. It is typically designed with a helical flute to facilitate chip evacuation and distribution of cutting forces. It also has a slight taper to help the user insert it accurately into the hole.

Because reamers are made of hardened and brittle materials, they are relatively easy to break, so it is important to be careful to keep the reamer aligned with the axis of the hole. When manually reaming a hole, the operator can only remove a small amount of material at once. If the tool bites into too much material, it is more likely to roll off the correct axis, resulting in a loss of accuracy and risk of tool breakage.

Because of human error, manual reaming is usually a little less accurate than machine reaming. Despite this, manual reaming is common in manufacturing shops and is one of the most important tools in a machinist’s toolbox.

Shell Reamer

Designed for larger holes – usually 3/4″ and above. They are individually fluted tips designed to fit onto existing shanks. This feature reduces their cost because they use less material and require fewer manufacturing steps. Shell reamers can be used with any standard groove type such as straight, twisted and spiral grooves. Counterclockwise vent slots are used for blind holes, and clockwise slots are more common.

Straight Flute Reamer

As the name implies, straight flute reamers have a chipformer groove parallel to the center axis of the reamer bit, which is suitable for materials that do not produce a lot of chips, such as brass and cast iron.

Chip evacuation can be a problem because the chipformer slots do not have an angle. It is best to use them with a through hole so that chips can fall through the bottom opening. In addition, they are not suitable as a manual reamer due to chip evacuation issues.

Floating Reamer

A normal reamer mounted on a floating reamer frame which is a device that carries a collet or chuck on a separate bearing system. The collet allows it to “float” on the drive shaft and follow the path defined by the existing hole. This innovative design eliminates a source of machine error in the reaming process. The drive can deviate from the hole and still obtain accurate results based on the centerline of the hole.

Other Types

- Jobbers Reamer

- Helical (Spiral)—Flute Reamer

- Structural Reamer

- Stub Screw-Machine Reamer

- Helically Fluted Chucking Reamer

- Chucking Straight Fluted Reamer

- Expandable Reamer

- …

How To Use Reamer

Reaming is a specialized operation that requires skill and practice, the user should follow the proper procedure depending on the reamer size and type.

The following is a general guide on how to use a reamer:

Setup Preparation

The first step is to set everything up. The workpiece should be mounted in a vise or fixture, which will prevent the workpiece from moving under the cutting forces. A moving workpiece will reduce reaming accuracy and may even destroy the reamer.

Marking the Pilot Hole

Once the workpiece is securely fastened in place, the next step is to drill the holes. First, the operator marks the center of the hole by using an appropriate marking device. Then, the hole is positioned with a spot drill or a countersunk hole. This process helps guide the drill to the center of the hole in the next step.

Drilling the Pilot Hole

During this step, it is important to select the correct drill size. A general tip is to use a drill bit that is 2-4% smaller than the final hole size. For example, if the final hole size is 10 mm, a 9.8 mm drill bit would be perfect.

Reaming

The hole and reamer are both lubricated to minimize friction. The reamers are mounted in their respective holders and aligned with the center of the hole, then the reamer is gently guided into the hole. A slight chamfer at the entrance end is useful in this process. Once inside the hole, the operator reamed the hole with the selected feed and speed parameters.

Cleaning

Periodically retract from the hole for additional lubrication and chip removal until the reaming process is complete. The hole should be thoroughly cleaned when finished, taking care not to damage the inside of the hole.

Difference Between Reamer, Drill Bit and Boring Tool

Reamer and Drill Bit

A drill bit is a cutting tool that has a helical cutting edge on its side and front. Their design allows them to have a large material removal rate. When drilling, you need the drill to make a hole in a completely solid material. The workpiece has no holes before drilling.

Like a drill, a metal reamer also has a cutting edge (usually helical), but only on the sides. Reamers finish the surface that has been drilled, and their main purpose is to remove a very small amount of material to produce a very smooth surface finish.

Reamer and Boring Tool

They are both cutting tools used for finishing holes and correspond to two types of hole machining, reaming and boring.

Boring is a hole enlarging operation whose main purpose is to remove material instead of producing a fine surface, and its material removal rate is also much higher than that of reaming. In addition, boring tools have a very unique geometry where the cutting edge is only near its entry face and not along its entire axis.

General Applications of Reamer

- Automotive: shaped holes in engine bores, valve covers and shafts.

- Aerospace: precision holes in fuselage, airframe, landing gear and other components.

- Manufacturing: precision machining and tapping of holes for special fastener sizes.

- Assembly: sizing holes for screws, nuts, rivets, and more.

Conclusion

The reamer, a tool used to extend or finish pre-drilled or bored holes to provide a good finish and precise dimensions, plays a core role in efficient and accurate hole machining. There are different reamers for different reaming operations, hoping that this article has cleared up some of your concerns.

Why CYCO

CYCO, the leading CNC machining service provider in the industry, has over two decades of experience in CNC machining.

Our state-of-the-art CNC machines and professional staff are ideally suited for providing you with the highest quality hole machining services.

If you still have questions about hole machining, please feel free to contact us for a no-cost consultation!