Composite machining is one of the most popular machining techniques in the field of mechanical machining in the world. It is an advanced manufacturing technology. Composite machining is to realize several different machining technologies on one machine tool. Composite machining is the most widely used and most difficult, that is, turning and milling composite machining. The turning and milling compound machining center is equivalent to a combination of a CNC lathe and a machining center. The emergence of the turning-milling compound machining center provides an effective solution for improving the machining accuracy and efficiency of aviation parts, and has a decisive influence on a country’s aerospace, military, scientific research, precision instruments and high-precision medical equipment industries.

Turning and milling compound machine tool is the fastest growing and most widely used CNC equipment among compound machining machine tools. The compounding of machine tools is one of the important directions in the development of machine tools. Compound machine tools also include various forms such as turning and milling combination, turning and milling combination, milling and grinding combination, cutting and 3D printing combination, cutting and ultrasonic vibration combination, laser and stamping combination, etc. The purpose of compounding is to make a machine tool have multiple Functional, can complete multiple tasks in one clamping, improve machining efficiency and machining accuracy.

Composite machining advantages

Compared with the conventional CNC machining process, the outstanding advantages of composite machining are mainly manifested in the following aspects.

(1) Shorten the product manufacturing process chain and improve production efficiency. Turn-milling combined machining can realize all or most of the machining procedures in one clamping, thus greatly shortening the product manufacturing process chain. In this way, on the one hand, the production auxiliary time caused by the change of clamping is reduced, and at the same time, the manufacturing cycle and waiting time of the fixture are reduced, and the production efficiency can be significantly improved. The main feature of mill-turn machining is the ability to machine all five sides in one setup. Avoid machining corners. If it is a linked machine tool, the C axis can rotate without limit, and the A axis can rotate about 130 degrees. The characteristics of these devices avoid disturbances during machining. The advantage of this is that the machining can be completed in one clamping, avoiding repeated positioning errors caused by multiple clamping. At the same time, it saves a lot of time and improves work efficiency. It can reduce the time from product to delivery and reduce the number of stocks.

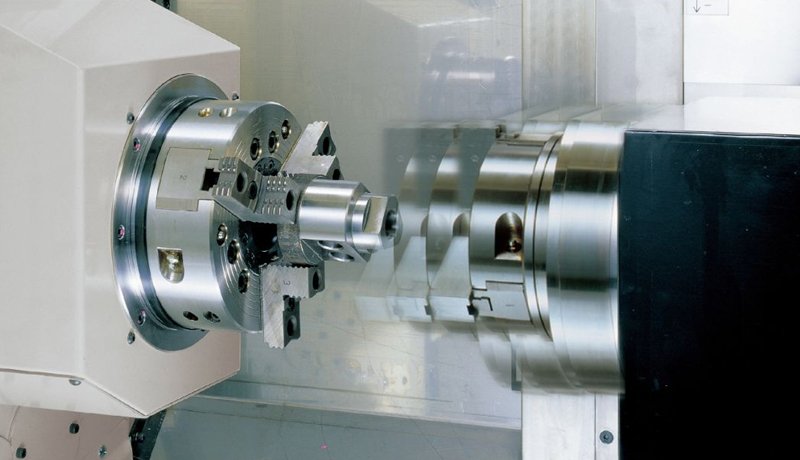

(2) Reduce the number of clamping and improve the machining accuracy. The reduction in the number of loading times avoids the accumulation of errors due to the transformation of the positioning datum. At the same time, most of the turning-milling compound machining equipment has the function of online detection, which can realize the on-site detection and precision control of key data in the manufacturing process, thereby improving the machining accuracy of products. Regular workpieces can be clamped directly with a three-jaw and four-jaw chuck, and irregular workpieces can be clamped with two pins on one side. At the same time, the turning and milling compound machining center can realize factory automation and reduce personnel.

(3) Reduce floor space and reduce production costs. Although the unit price of turning-milling compound machining equipment is relatively high, due to the shortening of the manufacturing process chain and the reduction of equipment required for the product, as well as the reduction of the number of fixtures, workshop floor space and equipment maintenance costs, the overall fixed assets can be effectively reduced The cost of investment, production operation and management. The left and right compound machining tools of turn milling combined machining usually have T (turning) function, which can be used from lathes to milling machines to vertical grinding machines. Current vertical grinder equipment is very expensive. By calculating the cost and machining rhythm, it can be found that the five-axis machine tool is more cost-effective. In the past, everyone’s production and machining may be based on engineering subdivision. The problem with this method of production is that there is a lot of waiting time that cannot be eliminated. The pre-commissioning of turning-milling compound machining equipment only needs to wait for time, but with the popularization of various machine simulation software, programming can be completed even by importing blank data, which greatly reduces the preparation work. Therefore, at present, auto parts and manufacturing are mainly based on five-axis.

Features of turning and milling compound machining

1. The turning-milling compound machining center uses a high-precision built-in spindle;

2. Freely movable operation panel improves working efficiency;

3. The model is mainly used for mass production of various small parts and complex parts for high-speed machining and diversified machining;

4. Especially the slender and complex process can be processed and formed at one time, and the automatic feeding device can be configured to improve efficiency;

5. Material details: cutting, copper, iron, aluminum alloy, stainless steel, Teflon and other materials.

The difference between turning milling machine and machining center

1. The turning-milling compound machining center is a machine tool with B-axis linkage and C-axis linkage that can be used for turning and milling. It can be said that all or most of a part can be processed on the turn-milling compound machine tool, so it is also called Small production line. It can not only improve the precision of products and the efficiency of machining products, but also greatly save the floor area of machine tools for enterprises. In the past, it was necessary to complete the machining of a part on several machine tools, but now only one machine can complete all the tasks. machining. This type of machine tool can also be divided into vertical milling and turning compound and horizontal turning and milling compound machine tool.

2. For the five-axis machining center, it can only do milling but not turning. Therefore, there are many limitations in machining. The turning-milling compound can cover the machining of the five-axis machining center, but the five-axis cannot do the turning-milling compound machining.

Application of turning and milling combined machining

Turn-milling composite machining has a wide range of applications in modern manufacturing. The wide application and development of turn-milling composite machining technology has made modern manufacturing more refined and highly standardized.

1. Manufacturing of aircraft aviation parts: Aircraft is one of the most complex mechanical devices in the world. Its manufacturing requires many parts, and these parts need to be guaranteed by high-precision turning and milling composite machining.

2. Mold machining: Mold manufacturing requires accurate positioning and high-precision machining technology. Turning and milling composite machining can realize the machining of complex shapes of parts, as well as some high-precision machining.

3. Sheet metal machining: Some complex sheet metal parts can be processed by using the turning-milling composite machining technology, such as car shells, computer shells, etc.

4. Gantry planer machining: The gantry planer is a large-scale machine tool, and its machining range is larger than that of turning and milling composite machining. It can process some super-large workpieces, such as high-speed train tracks, high bridges, etc.

5. Tool machining: Turn-milling compound machining with strong technological capabilities is more suitable for the machining of wearing parts such as tools, which can improve machining quality and reduce displacement errors.

Development status of turning and milling combined machining

Most of the turning-milling compound machining is completed on the turning center, and the general turning center just replaces the ordinary turret tool holder of the CNC lathe with a turret tool holder with a power tool, and the main shaft increases the C-axis function. Due to the limitation of the turret tool holder structure and external dimensions, the power of the power head is small, the speed is not high, and larger tools cannot be installed. Such a turning center is mainly used for turning, and the functions of milling and drilling are only for auxiliary machining. Driven tool holders are expensive, causing the cost of turning centers to remain high. Most of the economical turning and milling compound are XZC axis, that is, a rotating C axis is added to the chuck to realize the basic milling function.

Why Choose CYCO Machining

Professional Team Support: We have a team of professional engineers and technicians to provide professional support 24/7 to help you solve your problems.

Strictly Quality Control: We’re following strict quality control system to ensure quality prototypes and production parts.

Advanced Equipment: We have the same manufacturing and testing equipment. Your parts will be manufactured and tested using our state-of-the-art equipment.

Fast Turnaround: We follow a strict quality control system to ensure the manufacture of quality prototypes and production parts.