Overview of Forging

An important form of metal forming process, commonly used in the manufacture of important mechanical parts with high loads and severe working conditions, such as automotive parts, aircraft structural parts and engine components.

It is a processing method that utilizes forging machinery to apply pressure to a metal billet, causing it to undergo plastic deformation in order to obtain certain mechanical properties, shape and size of the part.

The forging process can be broadly categorized into free forging, die forging, hot forging, warm forging and cold forging for different types of metals, different scales of production and different processing requirements.

Forging has many advantages such as increasing the strength and improving the toughness of the material. Nonetheless, there are some challenges in the machining process that can lead to the appearance of forging defects, which can affect the quality of the final product.

Keep reading to explore more about forging defects with us.

Forging Defects Classification

According to the manifestation

- External defects: the size and shape do not meet the requirements, it is relatively easy to observe, such as surface cracks or shape and size errors.

- Internal defects: exist in the interior of the forgings and are not easily recognized, such as internal cracks, coarse crystals and segregation.

- Performance defects: reacting on the performance, which can only be known exactly after conducting experiments.

According to the process

- Raw material: such as non-metallic inclusions and scars.

- Unloading: for example, beveling and end cracks.

- Heating: e.g. decarburization and overheating.

- Forging: such as uneven grains and cracks.

- Cooling: cooling cracks and cooling deformation.

- Cleaning: e.g. excessive pickling and corrosion cracks.

Different causes usually produce different defects, but the same defect can also come from different processes. When analyzing the cause of a defect, it is important to analyze it as a whole, in addition to identifying the form and characteristics.

The following are some common forging defects:

Surface cracks

Usually occurs on bars in a straight line and in the same direction as the main deformation.

Causes:

- Uneven heating: If the heating process before forging is not uniform enough, it will lead to a big temperature difference between the inside and outside of the metal, resulting in thermal stresses and thus causing cracks.

- Excessive cooling rate: The material needs to be cooled after forging, but if the cooling rate is too fast, especially in certain areas, it may lead to cracks. This is usually associated with residual stresses and uneven cooling.

- Raw material: The presence of subcutaneous bubbles or inclusions within the material, these defects are exposed to the surface during the forging process and form cracks.

In addition, if there are scratches, pits and other damage on the surface of the material, the stress is concentrated during compression and cracks can easily be initiated.

- Over forging: If the material is over forged, it may lead to distortion and abnormal organization, which increases the risk of cracking.

- Dies: Improperly shaped and sized dies or badly worn dies may cause the metal to be impeded in its flow and to form cracks.

In addition, incorrect stock release or uneven die surfaces may lead to stress concentrations, which may also lead to forging cracks.

Solution:

To prevent forging cracks, parameters such as temperature and cooling rate need to be carefully controlled and optimized. Material selection, die design and quality control are also key factors in crack prevention.

It is also necessary to perform regular non-destructive testing (e.g., ultrasonic, magnetic particle and penetration testing) on forgings so that potential problems can be detected and repaired in a timely manner.

Coarse grain

During the forging process, the grain size of the material increases, resulting in a phenomenon of excessive or uneven grain size within the metal. This condition may lead to a decrease in the mechanical properties of the material.

Causes:

- Excessive heating temperature: If the heating temperature before forging is too high, it will cause the grains to grow, resulting in the formation of coarse crystals.

In addition, too high a heating temperature will also reduce the plasticity of the metal, affecting the forging effect.

- Deformation: If the deformation during forging is not large enough, it cannot effectively refine the grains and is easy to form coarse grains.

However, if excessive deformation is applied to the material, the grains may be elongated or deformed, which can also result in the formation of a coarse grain structure.

- Raw material: The presence of large intrinsic grain size or severe segregation in the raw material itself can affect the size and distribution of the grains after forging.

Also, incorrect alloy composition may lead to abnormal grain growth.

- Excessive holding time: Prolonged holding time at elevated temperatures will result in continued growth of metal grains and the production of coarse crystals.

Solution:

In order to reduce the occurrence of forging coarse crystals, it is necessary to carry out strict quality control of raw materials, optimize the parameters of the forging process as well as the use of appropriate heat treatment methods. Appropriate temperature and time during heat treatment can help adjust the grain structure and improve the material properties.

Moreover, the selection of suitable alloy compositions is also important, and appropriate alloying elements can be added to refine the grain and improve the mechanical properties of forged products.

Segregation

Uneven distribution of the alloying elements in the material occurs in the organizational structure, resulting in differences in the alloy composition in different regions, which may affect the mechanical properties and chemical properties of the final product.

Causes:

- Raw material: Compositional segregation may exist in the raw material itself, such as dendritic segregation and band segregation in castings. If these primitive segregations are not improved or eliminated during the forging process, they can lead to segregation problems in the final product.

- Uneven heating: The uneven distribution of alloying elements in the material can result from uneven heating during the forging process. This usually occurs with poor temperature control or insufficient heating time.

- Insufficient deformation: If the deformation during forging is not large enough, it will not effectively break up the original dendritic grain structure, allowing segregation to be retained.

- Differences in solubility of alloying elements: The solubility of different alloying elements in the material may be different, which may lead to higher solubility of certain elements during the deformation process, thus causing segregation.

- Multiple forging and repeated heating: If a part has to be forged and heated several times, each operation may aggravate the degree of segregation.

- Die design: Uneven or improperly shaped die surfaces can restrict the flow path of the metal, which can lead to localized areas of stress concentration, thus creating segregation.

Solution:

Forging segregation can lead to a reduction in material properties in certain areas, such as reduced strength and toughness. To mitigate the effects of forging segregation, measures such as optimization of forging process parameters and proper temperature control can be taken. In addition, the risk of segregation can be reduced by adding appropriate alloying elements to improve the fluidity of the metal.

Non-metallic inclusions

The presence of non-metallic substances such as oxides, sulfides and silicates within a metal, but also particles, bubbles and slag of different materials.

Causes:

- Raw material contamination: If impurities or non-metallic substances are present in the raw material and these inclusions are not eliminated during the forging process, they may be entrained in the final product during the forging process.

- Uncleaned tools and equipment: If forging tools and equipment are not adequately cleaned, they may contain dust and grease residues, which may be carried over into the forging process.

In addition, if the surface of the mold is not clean or flat, it may lead to some non-metallic substances entrapped in the forging process.

- Oxidization: Metals react with oxygen during the forging process to produce oxides, which may form inclusions.

- Porosity: There may be porosity in the raw material, which may deform or break during the forging process and form inclusions.

Solution:

To minimize non-metallic inclusions in forging, select high quality and clean raw materials to reduce the amount of impurities and inclusions. Ensuring that forging equipment and die surfaces are clean will also prevent residual contaminants. In addition, subsequent heat treatment processes may help to minimize the effects of inclusions and improve material properties.

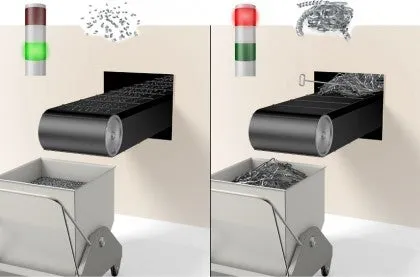

Decarburization

The loss of carbon from the surface of a metal by oxidation due to high temperatures and other factors, resulting a reduction in the carbon content of the material.

Causes:

- Heating at high temperatures: Forging usually involves heating the metal to high temperatures to make it moldable. However, the metal surface may react with the surrounding oxygen at high temperatures, resulting in the oxidation of the carbon on the surface to carbon monoxide or carbon dioxide.

- Mold material selection: some mold materials may have chemical reaction with the metal surface, resulting in decarburization.

- Cooling rate: The cooling rate after forging may also have an effect on decarburization. Rapid cooling may reduce the degree of decarburization.

- Influence of lubricants: Some lubricants contain oxidizing substances, which can accelerate oxidation and decarburization of the metal surface during the forging process.

- Inappropriate furnace gas composition: If the furnace gases contain large amounts of oxygen or water vapor, they can react with the carbon on the metal surface and lead to decarburization.

Solution:

In order to control and mitigate forging decarburization, mold materials with high oxidation resistance can be used to reduce the oxidation of the metal on the mold surface. Excessive decarburization can also be avoided by controlling the temperature and time of the heating process. In addition, the inert atmosphere used during the heating process, such as nitrogen or argon, can reduce the contact with oxygen and reduce the possibility of decarburization.

Banded structure

A special grain pattern that usually forms when a metallic material experiences an uneven strain or temperature gradient. This type of organization is characterized by grains that are distinctly elongated and aligned in one direction.

Causes:

- Uneven cooling: During the cooling of metallic materials, if the temperature distribution is not uniform, it may lead to differences in grain growth and tissue formation in different regions, resulting in the formation of a banded organization.

- Strain gradients: During forging or other deformation processes, if the strain is not uniformly distributed in the material, this may lead to non-uniformity in the organization and the formation of banded structures.

- Insufficient deformation: If the deformation during forging is not large enough, it cannot effectively break up the original grain structure, allowing the banded organization to be retained.

- Temperature gradient: In the process of high temperature heating and deformation, the temperature gradient may lead to differences in the direction of grain growth, the formation of banded organization.

- Material organization variations: Initial organization variations, such as uneven grain size or distribution, may exist in the material, which may also lead to the formation of banded tissue.

Solutions:

In some cases, banding may be unavoidable, but in other cases, banding can be mitigated or eliminated by optimizing process parameters, changing machining methods, or performing subsequent heat treatments. In summary, banding is a microstructural phenomenon that occurs during material processing and cooling and requires careful process control to adjust and optimize material properties.

Cooling deformation

A change in shape or size of a workpiece that occurs during cooling. This deformation may be caused by uneven thermal contraction of the material, which usually produces different cooling shrinkage rates in different parts or sections of the workpiece, resulting in changes in shape or size.

Causes:

- Uneven Temperature Distribution: During the forging process, there may be uneven temperature distribution inside and on the surface of the workpiece. Different cooling rates in different temperature zones lead to differences in shrinkage, thus causing cooling deformation.

- Material properties: Thermal expansion and cooling shrinkage of the material affects the deformation. Different types of metals have different rates of thermal expansion and cooling shrinkage, which may lead to different cooling deformations.

- Quality of raw materials: Compositional segregation and uneven grain size of raw materials may affect the cooling performance of the metal and lead to cooling deformation.

- Cooling medium: The use of different cooling mediums (e.g. air, water, oil) can lead to different cooling rates and affect the cooling deformation of the workpiece.

Solution:

To reduce forging cooling deformation, ensure uniform heating of the workpiece during the forging process to minimize the temperature gradient. At the same time, the crystal structure of the material can be changed by appropriate preheating and subsequent heat treatment to minimize the effect of cooling deformation. In addition, design simpler geometries to minimize the difference in cooling rates in different areas of the workpiece.

Uneven hardness

Uneven distribution of hardness within or on the surface of a metal. It is usually caused by inhomogeneous deformation of the material, or uneven temperature and alloying element distribution. Uneven hardness may lead to inconsistent performance of a part and affect its reliability in service.

Causes:

- Uneven temperature distribution: During the forging process, if the temperature of the metal material is not uniformly distributed, it may lead to uneven grain growth and organizational structure, which in turn affects the hardness.

- Uneven distribution of alloying elements: Uneven distribution of alloying elements in the material may lead to inconsistency in hardness.

- Heat treatment: If the temperature is not properly controlled or the cooling rate is not uniform during heat treatment, it may lead to uneven hardness of the metal.

- Uneven heating: The heating process before forging, if not uniform enough, will lead to a large temperature difference between the inside and outside of the metal, resulting in thermal stresses, thus affecting the hardness distribution of the metal.

Solution:

When selecting materials, ensure that they have a uniform organizational structure and distribution of alloying elements to reduce the possibility of uneven hardness. Then, ensure proper heating and temperature control during machining. Additionally, subsequent heat treatment processes, such as tempering and quenching, can be used to adjust the hardness distribution of the material and improve the uniformity of hardness.

Pickling corrosion

A chemical treatment process used to remove oxidized skin, rust, oxides and other surface impurities. However, too much time spent pickling or too high a concentration of acid can lead to severe corrosion of metal surfaces.

Causes:

- Excessive duration of pickling: If the duration of pickling is too long, it will lead to excessive corrosion of the metal surface, which will affect the quality and performance of the metal.

- High concentration of acid: The concentration of acid used in pickling is too high, which will accelerate the corrosion rate of the metal surface.

- Incomplete cleaning: If the cleaning process after pickling is not thorough enough, acid residue may be left behind, resulting in continued corrosion of the metal surface.

- Quality of raw materials: There may be subcutaneous bubbles, inclusions or other defects in the raw materials that are exposed to the surface during the pickling process and aggravate corrosion.

- Sensitivity of metal materials: Some metals are more sensitive to pickling and may require more careful handling.

Solution:

To minimize corrosion caused by excessive pickling, it is necessary to control the pickling time, acid concentration and temperature, as well as to ensure thorough cleaning. In addition, the appropriate composition and concentration of pickling solution should be selected according to the nature and requirements of the specific metal.

Conclusion

Understanding the different types of forging defects and how to avoid them, manufacturers can ensure that the final product is of high quality and meets the required specifications. For example, proper metal treatment, high-quality raw materials and an efficient cleaning process can prevent inclusions. Adequate lubrication, proper mold design and good metal flow help avoid surface distortion.

By taking the right and appropriate measures, manufacturers can minimize the costs associated with defects, reduce waste and improve the general quality of their products.

Therefore, in order to save time and costs, it is best to choose to work with a machining specialist such as CYCO. We, CYCO, will provide you with the best forging services with the most suitable materials, leading technology, specialized equipment and experienced staff.

Contact us now for more details about forging machining.