Casting surface finish is an important part of improving the casting quality to ensure its functionality and durability. It covers a range of processes from removing surface defects to enhancing surface properties.

Importance of Casting Surface Finish

Castings surface finish plays a vital role in the entire manufacturing process. It is important in several ways:

- Appearance enhancement: Surface finish is a critical step in determining the appearance of a product. Through the appropriate surface finish, porosity, inclusions and oxidized layers generated during the casting process can be removed. This makes the casting surface smoother and more uniform, which improves the overall appearance quality of the product.

- Corrosion resistance improvement: Castings may suffer from various environmental erosions during use, such as humid climate and chemical corrosion. Suitable surface finish, such as anti-rust coating or anodizing, can effectively improve the corrosion resistance of casting and extend its service life.

- Improvement of mechanical properties: Surface finish can adjust the casting surface finish, strength, toughness and other mechanical properties. Different treatment methods can realize targeted enhancement of casting performance.

- Enhancement of coating adhesion: Casting surface finish can improve the adhesion between the coating and the substrate. For products that need painting or coating, it ensures that the coating adheres firmly to the casting surface.

- Reduction of friction and wear: Surface finish reduces the roughness of the casting surface. This reduces the friction coefficient, improves the smoothness of the surface and slows down wear. This is particularly important in applications where high wear resistance is required.

- Conformity to design requirements: By carefully selecting and controlling the surface finish process, it is possible to adjust the size, shape and properties of specific areas of the casting.

Common Casting Surface Finish Methods

Common methods of casting surface finish have their unique principles, advantages…

Sandblasting / Shotblasting Cleaning

Principle: Through high-speed sand blasting or shot blasting equipment, impact particles to the casting surface.

Function: Remove oxidized layer, dirt and improve surface roughness.

Advantage: Remove casting defects, such as porosity, inclusions. Increase surface roughness and favor coating adhesion.

Suitable scope: Steel, cast iron, aluminum alloy and other types of metal. Applications that require high surface roughness.

Optimization: Control particle size and speed to ensure uniform surface coverage. Avoid over-treatment to create additional damage.

Anodizing

Principle: Place the casting in an electrolytic bath to form an oxide layer in an oxidizing solution.

Function: Improve the corrosion resistance and hardness of the castings.

Advantage: Increase corrosion resistance and hardness. Improve the appearance of castings and form a protective oxide film.

Suitable scope: Mainly used for aluminum alloys.

Optimization: Control electrolyzer parameters such as temperature and current density to adjust the thickness and uniformity of the oxide layer.

Electroplating

Principle: Through electrolytic chemical reaction, deposit metal on the surface of casting, such as nickel, chromium.

Function: Improve the surface hardness and brightness.

Advantage: Enhance surface brightness and improve appearance. Increase hardness and improve wear resistance.

Suitable scope: Steel, iron, copper and other metals.

Optimization: Control current density and plating solution composition to ensure uniform plating layer.

Grinding and Polishing

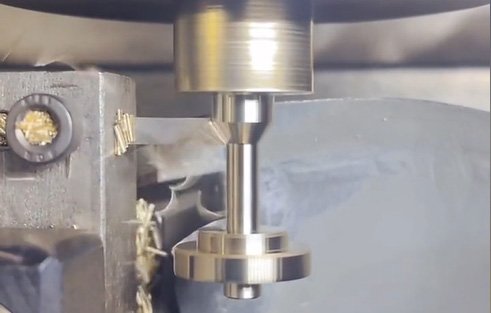

Principle: Use a grinding or polishing tool to remove surface imperfections.

Function: Improve surface finish.

Advantages: Better appearance and improved finish. Reduced friction and improved mechanical properties.

Suitable scope: Various metal materials.

Optimization: Selection of suitable abrasives and control of grinding parameters.

Chemical Treatment

Principle: Use acid, alkali and other chemical solutions to clean the surface of castings.

Function: Remove oxides and impurities.

Advantage: Eliminate corrosion and oxidation products to improve surface quality. Enhance the corrosion resistance of castings.

Suitable scope: Different metals and alloys.

Optimization: Control treatment time and concentration to prevent excessive corrosion.

Coating/Spraying

Principle: Form a coating on the surface of castings.

Function: Improve corrosion resistance and aesthetics.

Advantage: Enhance corrosion resistance. Beautify the appearance and improve the appearance quality.

Suitable scope: Widely applied to all kinds of metals.

Optimization: Select appropriate coating materials, control coating thickness and ensure uniform coverage.

Quality Testing of Casting Surface Finish

Quality testing of casting surface finish is an important part to ensure product quality and performance.

Visual Inspection

Principle: Observe the casting surface directly through human eyes to check for cracks, pores, defects, and so on.

Advantage: Simple and intuitive, can quickly find obvious surface defects.

Optical Microscope

Principle: Through the magnifying lens to observe the surface microstructure of the casting, to check the small defects.

Advantage: It can detect the subtle surface problems and improve the detection sensitivity.

Gloss Meter

Principle: Evaluate the surface finish by measuring the reflection and refraction of light.

Advantage: Provide quantitative surface finish data.

Electron Microscope Scanning

Principle: High resolution scanning of casting surfaces using an electron microscope to examine microstructure and defects.

Advantage: Offer more detailed information on the surface structure.

Coating Adhesion Test

Principle: Tensile, shear or tear testing of coatings using appropriate test equipment to assess coating adhesion.

Advantage: It can detect the firmness of the coating.

Chemical Composition Analysis

Principle: Test the composition of the casting surface to check whether the treatment process meets the requirements.

Advantage: Ensure that the surface finish does not affect the chemical composition of the material.

Electrochemical Testing

Principle: Detect the corrosion performance of coatings, anodized layers, and others by electrochemical methods.

Advantage: Assess the corrosion resistance of castings.

Hardness Test

Principle: Use a hardness tester to test the hardness of the casting surface finish to assess the effectiveness of the treatment.

Advantage: Provide information on surface hardness and the effect of treatment on hardness.

FAQs about Casting Surface Finish

- How are porosity and holes formed on the surface of castings?

Possible causes: Usually due to incomplete gas removal.

Solutions: Adopt proper pouring system, improve pouring process and control the quality of melt. - Why do cracks appear on the surface of castings?

Possible causes: It may result from internal stresses in the material, or it may cause by rapid cooling.

Solutions: Adjust the casting and cooling process to avoid rapid cooling, and use suitable annealing treatment. - What about coating flaking?

Possible causes: Incomplete surface preparation, uneven coating or insufficient coating adhesion.

Solutions: Ensure that the surface is clean and moderately rough before coating. Proper coating process and paint can improve the adhesion of the coating. - Why does rust appear on the surface of castings?

Possible causes: Improper surface preparation, lack of corrosion-resistant coating, broken oxide layer.

Solution: Apply corrosion-resistant surface finish, select suitable coating materials, and strengthen anti-corrosion measures. - What to do if the smoothness after surface finish does not meet the requirements?

Possible causes: Improper selection of surface finish, improper operation or wear of equipment.

Solutions: Adjust process parameters, improve operation skills, maintain and replace equipment. - How to solve the color inconsistency after casting surface finish?

Possible causes: Different degree of treatment for different parts or uneven concentration of treatment solution.

Solutions: Optimize the surface treatment process and control the uniformity of the treatment liquid. - What is the reason for the appearance of bubble holes in the coating?

Possible causes: Surface treatment with gas residue, high humidity in the coating environment, unsuitable coating materials.

Solutions: Improve the exhaust effect of surface finish. Ensure that the humidity of the coating environment is appropriate. Select suitable coating materials. - How to solve the uneven thickness of anodized layer?

Possible causes: Uneven flow of electrolyte, complex shape of castings.

Solutions: Optimize the design of electrolytic tank and control the flow of electrolyte. Adopt proper anodizing process. - What about the acidic and alkaline residue on casting surface after chemical treatment?

Possible causes: Chemical treatment is not thoroughly cleaned. Inappropriate pH of solution or incorrect neutralization.

Solutions: Thoroughly clean the surface of the casting to ensure that the residue is removed. Adjust the pH of the solution and ensure that it is properly neutralized.

Summary

Castings surface finish is a key technological step aimed at improving the appearance quality, corrosion resistance and mechanical properties of castings. The key is to select the appropriate method according to different materials and treatments, and to strictly control the treatment parameters. Quality testing ensures that the surface quality of the final product meets the design criteria and enhances reliability and performance. By identifying and solving common problems, manufacturers can optimize their processes, improve product quality and meet customer needs.

CYCO has over twenty years of experience in precision machining and manufacturing. We also specialize in precision casting machining, and we ensure superior casting surface finishes.

We have experienced engineers and technical experts. They are well versed in various surface finish methods and can provide professional advice or solutions according to customers’ needs.

We have established a comprehensive quality control system. We ensure the consistency and stability of casting surface finish through strict quality testing and monitoring.

We provide services covering the whole process of casting surface finish. From the initial cleaning,grinding and polishing of castings to the application of complex corrosion-resistant plating and special coatings. We are able to meet the diverse needs of our customers for casting performance and appearance.

If you have any questions about casting, please feel free to contact us!