With the development of industry and the wide application of industrial equipment, the use of bearings has become more and more extensive.

So, do you know what is bearing clearance? Do you know how to measure and adjust it before using a bearing?

Keep reading to explore more.

Definition of bearing clearance

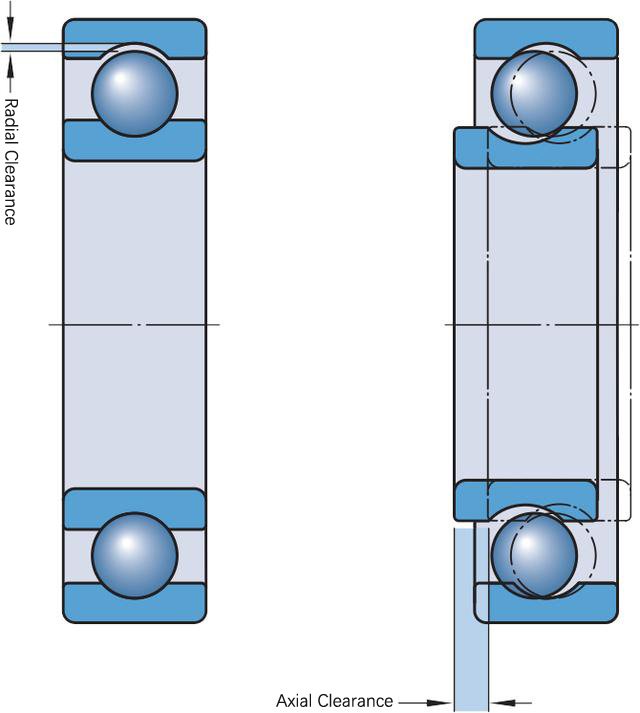

Bearing clearance is the intentional gap or space between the components of the bearing system, especially between the inner and outer rings of rolling element bearings. The clearance allows relative displacement between the inner and outer rings of the bearing. This clearance is necessary to accommodate thermal expansion, manufacturing tolerances and operating conditions of the bearing. Based on the direction of movement, they can be categorized as radial clearance and axial clearance.

Classification of bearing clearance

According to the direction of movement

- Radial clearance: without external load, the angle at which the inner ring of the bearing can rotate freely, or the maximum relative displacement of the two rings along the radial direction.

- Axial clearance: when there is no load, a ring is fixed, another ring moves along the axial direction from one extreme position to another extreme position.

By operating status

- Original clearance: refers to the radial and axial clearance in a free state before it is mounted on the shaft or bearing housing, generally determined by machining and assembly at the manufacturing plant. In this state, the inner and outer rings are not affected by any external loads.

- Assembly clearance: formed after a bearing is mounted on a shaft or in a bore. The assembly clearance is usually smaller than the original clearance because the actual clearance is reduced by the interference fit and preload during assembly.

- Working clearance: the actual running clearance in the working condition, which is influenced by load, temperature change and elastic deformation. An increase in the temperature of the inner ring during operation causes thermal expansion which reduces the bearing clearance. The action of the load produces elastic deformation in place of the rolling elements in contact with the raceways, which increases the bearing clearance. The structural characteristics of some bearings allow the operating clearance to be readjusted.

Factors affecting bearing clearance

The appropriate amount of clearance depends on the type of bearing, the intended application, and operating conditions.

Factors influencing the determination of bearing clearance include:

- Bearing type: different types of bearings have different designs and structures, so their radial and axial clearance ranges are also different.

- Material and hardness: the material of inner and outer rings and rolling elements as well as the hardness has a direct impact on the thermal expansion and elastic deformation of the bearing, which in turn affects the size of the clearance.

- Temperature changes: working temperature changes will lead to thermal expansion or contraction of bearings and mating parts, which will affect the size of the clearance.

- Speed and load conditions: high-speed or heavy-load applications may require specific clearance values to ensure proper lubrication, reduce friction, and prevent overheating.

- Application requirements: different applications may require specific amounts of bearing clearance. For example, precision machinery may require smaller clearances for accuracy, while heavy-duty applications may require larger clearances to cope with thermal expansion.

Proper clearance is important to ensure optimum performance of the bearing system and operation under a wide range of conditions. In many cases, bearing manufacturers will provide guidance or recommendations for clearance based on the specific type of bearing and intended use.

Effects of improper bearing clearance

Working clearance is an important quality indicator for rolling bearings and an important parameter in bearing applications. Improper bearing clearance has a significant impact on the operation and life of the equipment.

Excessive clearance

- Increase vibration and noise.

- Reduce rotational accuracy and affect the working performance of the machine.

- Exacerbate the impact between the rolling body and the inner or outer ring, which may lead to early fatigue damage.

- In high-speed operation, the rolling body may slip or fall off due to centrifugal force.

Insufficient clearance

- Increased frictional resistance can lead to higher temperatures and compromise lubrication.

- The increased contact stress between the rolling element and the inner or outer ring accelerates wear and fatigue.

- For some precision equipment, too small a clearance will reduce its working accuracy.

Uneven clearance

- Affect the equalization of load distribution and may lead to premature localized damage.

- Cause additional vibration and noise.

- Result in degradation of equipment performance and shortened service life.

Unstable clearance

- Cause abnormal wear of the internal parts of the bearing.

- Increase maintenance costs and downtime.

- Shorten the service life of the equipment.

Ensuring that bearing clearances are within proper limits is one of the key factors in keeping equipment running efficiently and safely. Regularly checking and adjusting bearing clearances can help minimize the occurrence of failures and improve equipment reliability.

Adjustment method of bearing clearance

Adjusting bearing clearance involves modifying the internal geometry or positioning of the bearing components to achieve the desired level of clearance. It’s important to note that not all types of bearings allow for adjustment of clearance, and certain bearings come with fixed clearances designed for specific applications. The adjustment process also depends on the type of bearing, such as ball bearings, roller bearings, or plain bearings.

Below are general methods for adjusting bearing clearance:

- Shim adjustment: radial clearance is changed by increasing or decreasing the thickness of shims between the shaft and the bearing housing. The thickness of the shims should be selected based on calculations or actual measurements.

- Adjusting screw: increase or decrease the clearance by rotating the adjusting screw, suitable for special design bearings with adjusting screw, such as some large thrust bearings.

- Preload adjustment: refers to the application of a certain axial force to the bearing under no-load conditions in order to reduce the actual clearance during operation. There are two ways of preload, one is internal preload, realized by using springs and rollers inside the bearing. The other is external preload, realized by axial positioning components such as shims, adjusting nuts and so on.

- Replacing bearings: in some cases, bearings with different clearance ratings can be replaced to achieve the desired clearance.

- Adjusting journal size: radial clearance can be adjusted by appropriately increasing or decreasing the journal diameter.

- Lubricant selection: the viscosity of the lubricant will also affect the working clearance of the bearing, and appropriate lubricant or grease can also be used to adjust the clearance indirectly.

- Thermal expansion adjustment: the clearance of a bearing can change due to temperature changes. In some applications, the initial assembly may need to account for thermal expansion to set the clearance.

- Hydraulic adjustment: some advanced systems use hydraulic methods to adjust bearing clearance. Hydraulics can be used to control the axial movement of the bearing assembly.

Summary

Bearing clearance has a significant impact on the operational performance and service life of equipment. It is very important to choose the right bearing clearance with regular checking and adjustment. This not only ensures optimal operating performance of the equipment, but also extends its service life and reduces failure rates and maintenance costs.

CYCO is a manufacturing specialist with over twenty years of experience in mechanical engineering and precision CNC machining. Our team has extensive experience in design, fabrication and assembly, which ensures that the bearing clearance of your product is as required.

At the same time, we provide professional technical support and customization services, you can get your expected products by working with us.

Contact us now for more information.