Plastic machining, also called plastic molding, is the process of machining plastics or synthetic resins into plastic products. Machining of plastic consists of several steps: batching, molding, machining, joining, finishing, and assembling currently. The last four steps, also known as secondary processing of plastic, are carried out after the plastic has been molded into products or semi-products.

Steps in plastic machining

Step 1 Batching

The first step in plastic machining process. The raw materials needed are not only polymers, but also some stabilizers, plasticizers, colorants and other plastic auxiliaries. The performance of plastic products processed and molded in this way will be greatly improved, and production costs can also be reduced.

Step 2 Molding

The most critical step in plastic machining process, we have to make plastic in various forms into blanks of the desired shape. There are many methods of molding, and the choice is primarily based on the type and initial form of the plastic and the size and shape of the product.

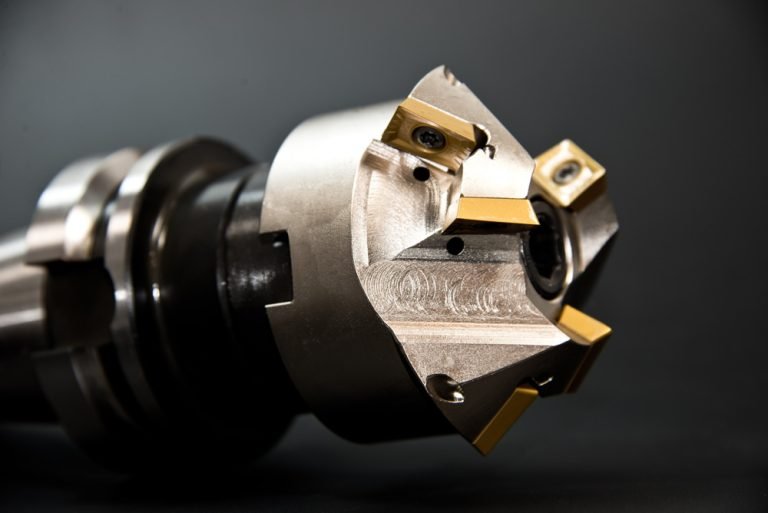

Step 3 Machining

Can be seen as an auxiliary process to molding. It can be used to make some plastic products with precise dimensions or in small quantities. However, compared to metal and wood, plastic has completely different properties. The tools and cutting speeds used in machining should be in accordance with the characteristics of the plastic.

Step 4 Joining

This step is to join the plastic parts together, by welding and bonding. Welding methods mainly include hot-gas welding, fusion welding, high frequency induction welding, friction welding, ultrasonic welding and more. The bonding method uses an adhesive, such as hot-melt adhesive.

Step 5 Finishing

The purpose of this step is to beautify the surface of the plastic product, usually by mechanical grinding or polishing. It can also be painted or electroplated to change the color.

Step 6 Assembling

The final step in plastic machining process, combining individual plastic parts together into a complete plastic product.

Above are the main steps in plastic machining process CYCO uses. How about CYCO’s plastic machining process? Below are some of the plastic machining processes used by CYCO.

Processes for plastic machining

Injection

Products are usually molded by using rubber injection molding and plastic injection molding. Injection can also be divided into compression molding and die casting, it is mainly operated by injection molding machines and molds. Injection molding machines make thermoplastic or thermosetting materials into plastic products of various shapes by using molds.

Extrusion

The material passes through machine barrel and screw, plasticizing by heat and being pushed forward by screw simultaneously, then through the heads into a variety of cross-section products or semi-products.

Rotation

The method is to add a certain amount of plastic material (liquid or powder) into the mold. After the mold is closed, rotate it through the vertical rotation axis while heating it. The raw materials in the mold are evenly distributed on the surface, and the required products can be obtained after cooling and demolding.

Blow molding

A rapidly developing method of plastic machining. The parison obtained by extrusion or injection of thermoplastic resin is put into the mold while it is hot (or heated to a softened state), and compressed air is passed into the parison immediately after the mold is closed. Parison will expand and cling to the inner wall of the mold, then we can get all kinds of plastic products after cooling and demolding.

Adsorption

After the flat plastic sheet is softened by heat, adsorb it on the surface of the mold by vacuum, then it can be molded after cooling.

Compression molding

Plastic in powder, granule or fiber form is placed into a mold at the molding temperature, then the mold is closed and the pressure is increased to form and solidify the plastic. This method can be used for thermosets, thermoplastics and rubber materials.

Calendaring

The molten thermoplastic is extruded and stretched through the gap of two or more antiparallel rotating rollers, and then becomes a continuous sheet product with specific dimensions and quality requirements, and finally molded by natural cooling. It is often used to produce plastic films and sheets.

Expansion molding

Adding the appropriate blowing agent to the foamed material (e.g. PVC, PE and PS) creates a microcellular structure in the plastic. Almost all thermoset and thermoplastic plastics can be made into foam plastic, and expansion molding has become an important area in plastics machining.

Summary

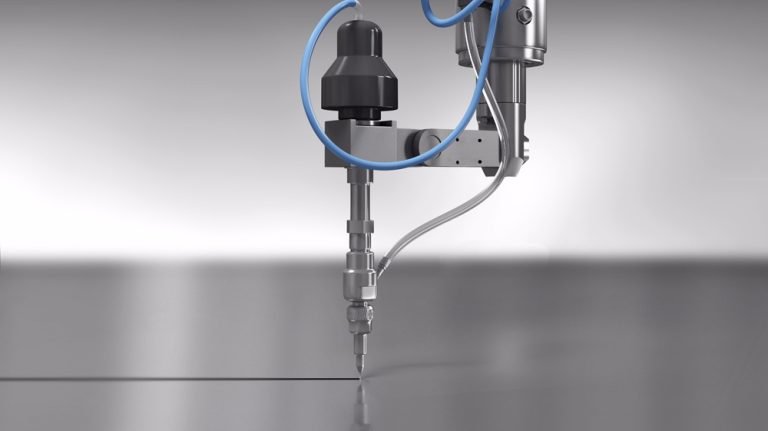

Choosing the right machining technology can be very challenging, so you need to outsource to a plastics CNC service provider. CYCO offers customized CNC machining services for plastics and can help you create or design prototypes based on your needs.

We specialize in CNC machining processes for plastic materials. CYCO can select the most appropriate machining method for your needs and materials, and our team of professionals can provide expert advice on process selection.

Upload your design to get a instant quote now and feel free to contact us for more information.