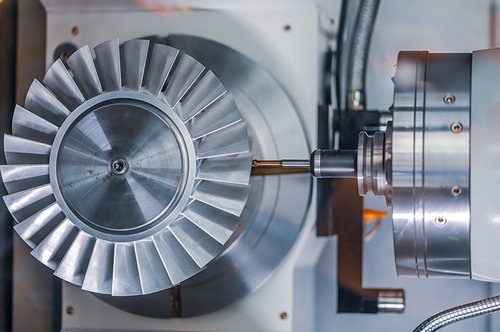

5-Axis CNC Machining Service

CYCOSPRAY’s CNC 5-axis machining service can create high-precision, complex-shaped components. We offer competitive prices and quality assurance.

- High Precision: Standard dimensional tolerance of ±0.005mm(0.0002in)

- Various CNC machines: 3-axis, 4-axis, and 5-axis CNC machines

- Various Work Techniques: CNC milling, CNC turning, wire EDM, etc.

- Get your products and parts ready in as fast as 24 hours

- Certifications: ISO9001:2015, IATF 16949:2016

What is 5-axis machining

5-axis machining is an advanced CNC (Computer Numerical Control) machining technique that involves moving a cutting tool along five different axes simultaneously. Traditional machining methods, such as 3-axis machining, involve cutting material using tools that move along three primary axes: X, Y, and Z. In contrast, 5-axis machining adds two more axes of rotation, typically denoted as A and B.

- X-Axis: Horizontal movement from left to right.

- Y-Axis: Horizontal movement from front to back.

- Z-Axis: Vertical movement up and down.

- A-Axis: Rotation around the X-axis.

- B-Axis: Rotation around the Y-axis.

The simultaneous movement along these five axes allows the cutting tool to approach the workpiece from multiple angles and orientations. This capability is particularly beneficial when machining complex and intricate parts, as it enables the tool to reach areas that would be challenging or impossible with fewer axes.

Our CNC Precision Machining Capabilities

Count on our on-demand CNC precision machining services for your parts on time, every time. Achieve outstanding results with our CNC milling and turning capabilities in as fast as five days.

CNC Milling Service

3 Axis, 4 Axis and 5 Axis CNC Machining Service for simple and complex geometries parts.

CNC Turning Service

CNC turning with live tools combines lathe and milling capabilities to machine parts with cylindrical features.

Turning-Milling Compound Machining Service

Combination of CNC lathe and machining center.

CNC Precision Machining

40 sets of CNC, more than 200 lathes and other machining equipment, 24-hour shifts, two physical factories

Advantages of 5-Axis Machining

Complex Geometries

5-axis machining allows for simultaneous movement along multiple axes, enabling the machining of complex and intricate shapes and geometries with a single setup.

Enhanced Precision

Continuous toolpath optimization in 5-axis machining results in higher precision and surface finish. This is particularly crucial for industries where tight tolerances are essential.

Increased Efficiency

5-axis machining enables more efficient machining of complex parts in a single setup, reducing overall production time and improving workflow efficiency.

Reduced Scrap Rates

Minimized material waste due to optimized toolpaths and reduced the need for additional setups, leading to lower scrap rates.

Adaptability to Industry Demands

5-axis machining meets the demands of industries such as aerospace, automotive, and medical, where complex and precise components are frequently required.

Higher Productivity

The combination of reduced setup times, increased efficiency, and improved tool life contributes to higher overall productivity in manufacturing processes.

3-Axis, 4-Axis, And 5-Axis CNC Machining Features comparison

| Feature | 3-Axis CNC Machining | 4-Axis CNC Machining | 5-Axis CNC Machining |

| Axes of Movement | X, Y, and Z axes for linear movement. | In addition to X, Y, and Z, it includes a rotary axis (either A or B). | Movement along both A and B axes simultaneously. |

| Complexity | Suitable for simple and moderately complex parts with flat or slightly contoured surfaces. | Suitable for parts that require rotary features, such as holes around a cylinder. | Ideal for highly complex parts with intricate shapes and multi-sided machining. |

| Setups | Multiple setups may be required for machining complex geometries. | Fewer setups compared to 3-axis for parts with rotational features. | Minimal setups required due to the ability to approach the workpiece from various angles. |

| Precision | Good precision for basic shapes and components. | Improved precision for components requiring rotation. | Highest precision, enabling tight tolerances and superior surface finish. |

| Applications | Commonly used for general machining, milling, and drilling operations. | Used in applications where rotational features are critical, such as aerospace and automotive components. | Widely used in aerospace, medical, and other industries for intricate and precise components. |