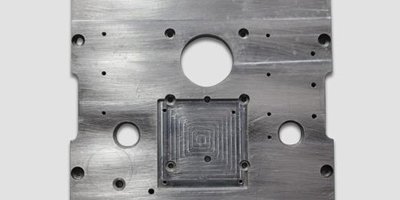

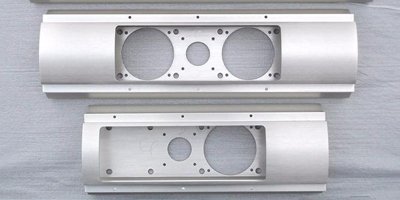

Aluminum parts CNC machining

Specialize in CNC machining, CYCOSPRAY will accompany your aluminum machining project from prototype design to final aluminum parts manufacturing with our complete CNC aluminum machining services.

- High Precision: Standard dimensional tolerance of ±0.005mm(0.0002in)

- Various CNC machines: 3-axis, 4-axis, and 5-axis CNC machines

- Various Work Techniques: CNC milling, CNC turning, wire EDM, etc.

- Get your products and parts ready in as fast as 24 hours

- Certifications: ISO9001:2015, IATF 16949:2016

Introduction to aluminum CNC machining

CNC machining is one of the most versatile manufacturing processes available today, and this process is compatible with a wide range of materials. Aluminum is one of the most popular materials for CNC machining applications, and very few substances can match its amazing versatility. Aluminum is highly machinable and relatively cheap, making it ideal for CNC machining. Manufacturers can machine aluminum three or even four times faster than other commonly materials such as steel and titanium. CNC machining of aluminum alloys provides manufacturers huge flexibility for manufacturing their products.

Benefits of aluminum CNC machining

Aluminum has several benefits of CNC machining making the process easier. The main benefits of CNC machining of aluminum are as follows:

- Good machinability

- High strength-to-weight ratio: both strong and lightweight

- High corrosion resistance

- Recyclable

- Lower production costs

- Greater electrical conductivity

- Resistant to low temperatures

- Versatility

- Heat tolerance

Our tips for avoiding distortion in CNC aluminum machining

Eliminate the inherent stress within the aluminum material

2 common ways used to eliminate the internal stress are natural or artificial aging and vibration treatment.

Choose a proper fixture for the aluminum workpiece

For thin-walled aluminum parts with poor rigidity, the methods below can help to improve machining accuracy:

Fill the inside of the workpiece with a medium to improve rigidity.

Use suction cups to make clamping force well distributed along with the thin plate.

Choose a pneumatic or mechanical vise for smaller or odd-shaped parts.

Use a vacuum table for large sheet material.

Improve the ability of the cutting tool

The short tool is the first choice cause a longer tool may induce the tool deflection on your finished parts. The material and geometric parameters of the tool have an important influence on the cutting force and cutting heat.

Select a suitable machining process

The aluminum CNC machining processes generally take four steps: rough machining – semi-finish machining – clear corner machining – finishing. When it comes to high accuracy, it can be taken into consideration that the number of semi-finishing operations should be increased and a uniform machining allowance should be sustained.

Use appropriate methods of operation

select the appropriate feed, spindle speed rates, and depth of cut; Symmetrical machining for the front and back of the workpiece; Machine all cavities of the workpiece with multi-layer; Use drilling and then milling when machining parts with a cavity.

Our technologies for aluminum machining

Generally, aluminum CNC machining is not a standalone production process. CYCOSPRAY has combined CNC milling, CNC turning and other manufacturing processes to expand the manufacturing capabilities of the aluminum alloy prototypes, save time and cost.

CYCOSPRAY offers advanced 5-axis CNC milling aluminum, which significantly increases the range of possibilities for machining various types of aluminum parts. Our advanced 5-axis CNC machines make it possible to complete all styles of aluminum milling tasks, no matter how many parts your assembly is composed of, we can handle all kinds of aluminum milling projects that require high precision and complex shape machined parts, and provide extremely tight tolerances and excellent surface finish.

Extrusion is the process of forcing molten material through an aperture in in a die, producing an elongated component with a continuous profile. It is an effective method for producing parts with superior surface finishes and complex cross sections,these cross sections must be consistent throughout the part, so modifications are required after extrusion. Combining aluminum extrusion and CNC machining is a great way to produce resilient parts with complex cross-sections and irregular geometries.

Investment casting produces parts with good surface finish and high dimensional accuracy. This process also has a unique advantage: it can be used to make more complex parts than die casting, without parting lines on thesurface.

A manufacturing process in which molten metal is pressed into a mold, and die cast aluminum parts typically have excellent surface finish and dimensional consistency. Because it is expensive to manufacture the steel molds, they are generally used for mass-produced parts. If cost reduction is more important than ensuring high accuracy, gravity casting may be used to instead of pressure casting.

Many machinable aluminum alloys are also adaptable to the time-honored forging process. Forged aluminum parts can be post-machined on CNC machining centers, which is an advantage over pure machining. Forged parts are usually stronger than their counterparts.

How to choose right materials for aluminum CNC machining?

Aluminum is a material with a large number of advantageous properties, it is available in many series and grades, with more than two decades of experience, CYCO will help you select the perfect material that will meet your expectations.

Our main considerations are as follows:

Hardness: directly related to the chemical composition of aluminum alloys, and different states also have an effect on it. From series 7 to series 1, the hardness has gradually decreased.

Strength: an important factor to be considered when designing products, especially when aluminum alloy components are used as structural parts, suitable aluminum alloys should be selected according to the pressure they are subjected to. Pure aluminum has the lowest strength, while heat-treated aluminum alloys of series 2 and series 7 have the highest strength. There is a positive correlation between hardness and strength.

Corrosion resistance: series 1 has the best corrosion resistance, series 5 performs well, followed by Series 3 and 6, with series 2 and 7 being poorer.

Weldability: most aluminum alloys can be welded, especially some series 5 aluminum alloys, which are designed for welding. However, some aluminum alloysof the series 2 and series aredifficult to weld.

CYCOSPRAY Machining Surface Finishes Services

Surface Finishes can not only improve the appearance of CNC machined parts, but also increase the functionality of the internal parts, wear resistance and corrosion resistance, and extend the service life of the parts.

This finishing option has the shortest turnaround time. Parts have visible tool marks as well as potentially sharp edges and burrs that can be removed upon request.

Smooth machining is similar to last "As machined" finish, but machine marks are less obvious. Parts are machined at a lower feed speed without manual polishing.

The method of applying the grinding brush to the surface, it produces a uniform surface, but visible lines is its feature.

Materials: ABS,Aluminum,Brass,Stainless Steel,Steel

Parts are bead blasted with glass beads to produce a uniform grainy texture and reduce processing marks.

Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

The vibrating medium rolls over the machined part to remove sharp edges and burrs, and the roll can be used to remove machine marks on the outer surface. Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

Bead blasting followed by anodizing (type II) matte surface finishing to create a uniform matte finish, the colors are naturally matte. It is ideal for improving corrosion resistance and aesthetics.

The material is brushed to form uniform oriented particles and then anodized to make it shiny. It forms a hard, wear-resistant oxide layer on the surface of the part to enhance its durability and corrosion resistance.

By anodizing the surface of a machined part for CNC milling, CNC turning, or 2-axis, 3-axis, or 5-axis CNC machining, a thick and durable oxide layer can be formed.

Through a chemical conversion process, metals such as aluminum and magnesium are coated with a thin protective film that gives excellent corrosion resistance and enhances the adhesion of subsequent coatings on CNC machined parts.