CNC Milling Service

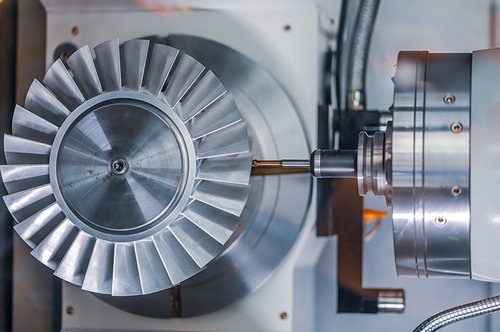

CYCOSPRAY cutting-edge CNC milling technologies include multi-axis milling, high-speed milling, automated tool changes, adaptive machining, and multi-tasking milling to reduce downtime and improve overall efficiency. Our equipment uses sensors and real-time data to adjust cutting parameters in real-time to improve precision and surface finish quality.

CYCOSPRAY is the high-quality precision CNC milling services you can trust. Competitive pricing and fast lead times.

Our CNC Machining Service Capabilities

Count on our on-demand CNC machining services for your parts on time, every time. Achieve outstanding results with our CNC milling and turning capabilities in as fast as five days.

CNC Precision Machining

40 sets of CNC, more than 200 lathes and other machining equipment, 24-hour shifts, two physical factories

CNC Milling Service

3 Axis, 4 Axis and 5 Axis CNC Machining Service for simple and complex geometries parts.

CNC Turning Service

CNC turning with live tools combines lathe and milling capabilities to machine parts with cylindrical features.

Turning-Milling Compound Machining Service

Combination of CNC lathe and machining center.

Our CNC Milling Services

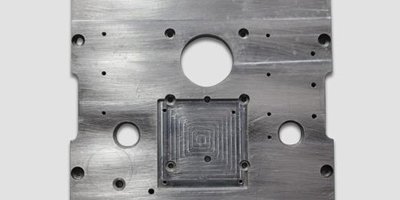

CNC milling service widely used to create parts and mold components with complex structure. It has high processing efficiency. Special details such as holes, threads, sealing grooves, irregular angles and deep holes can meet strict precision tolerance requirements.

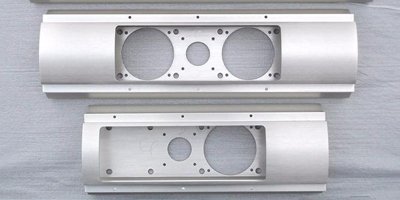

CNC Milling is suitable for small-batch prototype manufacturing of 1-100 pieces, and can also meet the manufacturing of tens of thousands of large-volume parts, and has good accuracy, consistency and other advantages.

CNC Milling Material

Metals are the most common material for CNC milling, including stainless steel, titanium, brass/copper, bronze, zinc, magnesium, aluminum, etc. Besides the various metal materials, CYCOSPRAY precision CNC milling service can also handle several plastics such as PVC, nylon, and PEEK. Other mediums like woods and foams are used with CNC milling as well.

CNC Milling Surface Treatments

CYCOSPRAY has been providing customers one-stop CNC machining service with 30+ surface treatments for a long time. Common surface treatments include: powder coating, painting, sandblasting, electroplating, electrophoresis, blackening, laser engraving, silk screen printing , CD pattern, etching, highlighting, polishing, anodize, thick film oxidation, micro-arc oxidation and so on.

CYCOSPRAY Machining Surface Finishes Services

Surface Finishes can not only improve the appearance of CNC machined parts, but also increase the functionality of the internal parts, wear resistance and corrosion resistance, and extend the service life of the parts.

This finishing option has the shortest turnaround time. Parts have visible tool marks as well as potentially sharp edges and burrs that can be removed upon request.

Smooth machining is similar to last "As machined" finish, but machine marks are less obvious. Parts are machined at a lower feed speed without manual polishing.

The method of applying the grinding brush to the surface, it produces a uniform surface, but visible lines is its feature.

Materials: ABS,Aluminum,Brass,Stainless Steel,Steel

Parts are bead blasted with glass beads to produce a uniform grainy texture and reduce processing marks.

Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

The vibrating medium rolls over the machined part to remove sharp edges and burrs, and the roll can be used to remove machine marks on the outer surface. Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

Bead blasting followed by anodizing (type II) matte surface finishing to create a uniform matte finish, the colors are naturally matte. It is ideal for improving corrosion resistance and aesthetics.

The material is brushed to form uniform oriented particles and then anodized to make it shiny. It forms a hard, wear-resistant oxide layer on the surface of the part to enhance its durability and corrosion resistance.

By anodizing the surface of a machined part for CNC milling, CNC turning, or 2-axis, 3-axis, or 5-axis CNC machining, a thick and durable oxide layer can be formed.

Through a chemical conversion process, metals such as aluminum and magnesium are coated with a thin protective film that gives excellent corrosion resistance and enhances the adhesion of subsequent coatings on CNC machined parts.

CYCOSPRAY CNC Milling Service

CNC milling is a process of using computer numerical control (CNC) to create three-dimensional objects from a solid block of material. CNC milling machines use a rotating cutter to remove material from the block until the desired shape is achieved.

At CYCOSPRAY, we offer high-quality CNC milling services that are designed to meet the needs of our clients. Our state-of-the-art CNC milling machines are capable of producing complex parts with precision and accuracy.

Our CNC milling services offer a number of advantages, including:

- Precision: Our CNC milling machines are capable of producing parts with high precision and accuracy. This ensures that the parts we produce meet the exact specifications of our clients.

- Efficiency: Our CNC milling machines are highly efficient, which means that we can produce parts quickly and at a lower cost than traditional machining methods.

- Versatility: Our CNC milling machines are capable of producing parts in a wide range of materials, including metals, plastics, and composites.

- Customization: Our CNC milling services are highly customizable, which means that we can produce parts that meet the unique needs of our clients.

CYCOSPRAY CNC Milling offers a number of advantages and features that make us the premier CNC milling service provider. These include:

- State-of-the-art equipment: Our CNC milling machines are equipped with the latest technology, which ensures that we can produce parts with high precision and accuracy.

- Experienced team: Our team of experienced machinists has the knowledge and expertise to produce parts that meet the exact specifications of our clients.

- Quality control: We have a rigorous quality control process in place to ensure that every part we produce meets our high standards.

- Competitive pricing: We offer competitive pricing for our CNC milling services, which means that our clients can get high-quality parts at a lower cost.

If you are looking for a CNC milling service that offers precision, speed, flexibility, quality, and expertise, then CYCOSPRAY CNC Milling is the perfect choice for you. Contact us today to learn more about our services and how we can help you with your next project.