CNC Turning Service

CYCOSPRAY is a leading manufacturer of CNC-turned parts delivering excellent quality flexibly. Our highly skilled engineers, designers, and procurement teams ensure our services are provided on time and within budget.

- One-off rapid prototype part can be created as fast as in one day

- Long-term run high volume CNC turning production

- ISO 9001:2015 Certified

- PPAP and FMEA for automotive clients

- Automatic machinery, experienced engineers, and 100% QC assurance

Our CNC Machining Capabilities

Count on our on-demand CNC machining services for your parts on time, every time. Achieve outstanding results with our CNC milling and turning capabilities in as fast as five days.

CNC Precision Machining

40 sets of CNC, more than 200 lathes and other machining equipment, 24-hour shifts, two physical factories

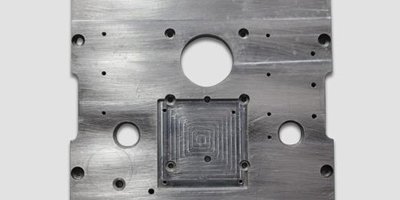

CNC Milling Service

3 Axis, 4 Axis and 5 Axis CNC Machining Service for simple and complex geometries parts.

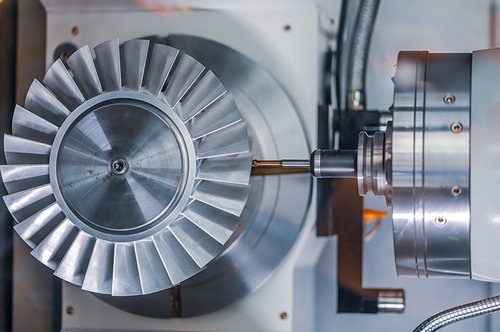

CNC Turning Service

CNC turning with live tools combines lathe and milling capabilities to machine parts with cylindrical features.

Turning-Milling Compound Machining Service

Combination of CNC lathe and machining center.

Why Choose Our CNC Turning Services

We’re committed to reducing friction at every stage, so you can be as delighted with the speed of your CNC Turned parts’ arrival as you are with their exceptional quality. Order now to receive your parts in as little as 5 days!

Our standard CNC tolerance is +/- 0.127mm, and when you use our tolerance configurator, you can expect precision machining to be +/- 0.005mm.

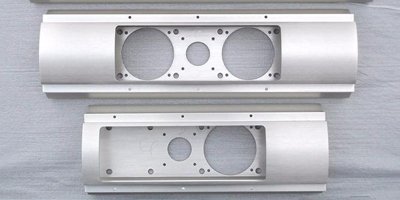

We offer over 60 production-grade materials including metal, plastic, and ceramic, and take great care to ensure the right material is used for every part.

We offer high-quality finishing processes for most CNC Turned parts; including anodizing, polishing and plating, heat treatment, powder coating, and more.

CYCOSPRAY Machining Surface Finishes Services

Surface Finishes can not only improve the appearance of CNC machined parts, but also increase the functionality of the internal parts, wear resistance and corrosion resistance, and extend the service life of the parts.

This finishing option has the shortest turnaround time. Parts have visible tool marks as well as potentially sharp edges and burrs that can be removed upon request.

Smooth machining is similar to last "As machined" finish, but machine marks are less obvious. Parts are machined at a lower feed speed without manual polishing.

The method of applying the grinding brush to the surface, it produces a uniform surface, but visible lines is its feature.

Materials: ABS,Aluminum,Brass,Stainless Steel,Steel

Parts are bead blasted with glass beads to produce a uniform grainy texture and reduce processing marks.

Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

The vibrating medium rolls over the machined part to remove sharp edges and burrs, and the roll can be used to remove machine marks on the outer surface. Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

Bead blasting followed by anodizing (type II) matte surface finishing to create a uniform matte finish, the colors are naturally matte. It is ideal for improving corrosion resistance and aesthetics.

The material is brushed to form uniform oriented particles and then anodized to make it shiny. It forms a hard, wear-resistant oxide layer on the surface of the part to enhance its durability and corrosion resistance.

By anodizing the surface of a machined part for CNC milling, CNC turning, or 2-axis, 3-axis, or 5-axis CNC machining, a thick and durable oxide layer can be formed.

Through a chemical conversion process, metals such as aluminum and magnesium are coated with a thin protective film that gives excellent corrosion resistance and enhances the adhesion of subsequent coatings on CNC machined parts.

CYCOSPRAY CNC Turning - Precision Machining Services

At CYCOSPRAY, we specialize in providing high-quality CNC turning services to meet the diverse needs of our clients. Our state-of-the-art CNC turning centers are equipped with advanced technology and skilled operators, ensuring that we deliver precise, accurate, and efficient machining solutions. With our commitment to excellence and customer satisfaction, we strive to exceed your expectations in every project we undertake.

Features of CYCOSPRAY CNC Turning:

- Advanced CNC Turning Centers: Our CNC turning centers are equipped with the latest technology, ensuring high precision and accuracy in every project.

- Skilled Operators: Our team of experienced and skilled operators are dedicated to providing the best CNC turning services, ensuring that your project is completed to the highest standards.

- Wide Range of Materials: We work with a variety of materials, including metals, plastics, and composites, to meet the specific requirements of your project.

- Customized Solutions: We offer customized CNC turning solutions to cater to your unique project requirements, ensuring that you receive the best possible results.

- Fast Turnaround Time: Our efficient processes and dedicated team ensure that your project is completed within the shortest possible time, without compromising on quality.

- Quality Assurance: We adhere to strict quality control measures, ensuring that every component we produce meets the highest standards of quality and precision.

Benefits of CYCOSPRAY CNC Turning:

- Precision and Accuracy: Our advanced CNC turning centers and skilled operators ensure that your components are machined with the highest level of precision and accuracy.

- Cost-Effective Solutions: Our efficient processes and competitive pricing make our CNC turning services a cost-effective solution for your machining needs.

- Reduced Lead Time: With our fast turnaround time, you can expect your project to be completed quickly, helping you meet your deadlines and reduce lead time.

- Consistent Quality: Our strict quality control measures ensure that every component we produce is consistent in quality, ensuring that your project meets the highest standards.

- Scalability: Our CNC turning services can easily accommodate both small and large production runs, making it a scalable solution for your machining needs.

- Expert Support: Our team of experts is always available to provide support and guidance throughout the entire process, ensuring that your project runs smoothly from start to finish.

If you are looking for a CNC turning service that offers precision, speed, flexibility, quality, and expertise, then CYCOSPRAY CNC Turning is the perfect choice for you. Contact us today to learn more about our services and how we can help you with your next project.

- We offer a wide range of materials to choose from, including steel, aluminum, brass, and plastic.

- We can produce parts with a wide range of tolerances, from +/-0.001" to +/-0.0001".

- We can produce parts with a wide range of finishes, including machined, polished, and anodized.

- We offer a variety of customization options, including custom features, custom finishes, and custom packaging.

We are confident that we can meet your CNC turning needs. Contact us today to learn more about our services and how we can help you with your project.