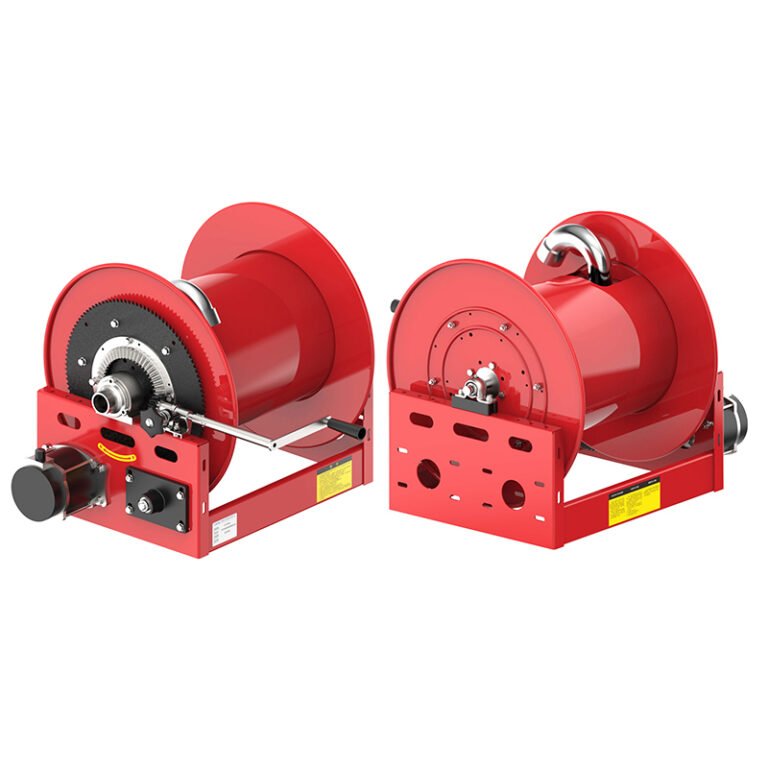

Industrial Hose Reels Machining

We specialize in the design and manufacturing of industrial hose reels, offering multiple configurations, materials, and performance grades for factories, chemical plants, cleaning industries, automotive workshops, fire stations, and more.

- Heavy-Duty, Long-Life, Fully Customized Solutions

- Made of stainless steel, carbon steel and other materials

- Various Work Techniques: CNC milling, CNC turning, wire EDM, etc.

- Stamping, spinning, welding, and machining processes

- Certifications: ISO9001:2015, IATF 16949:2016

Manufacturing Capabilities

Our complete production system ensures high quality and consistency.

Metal Fabrication

- Laser cutting

- CNC bending

- Automated welding

- CNC machining

- Powder coating / painting / polishing

Assembly & Testing

- Rotary joint sealing test

- Hose pressure test

- Retraction durability test

- Corrosion and wear-resistance inspection

Engineering & Design

- Structural design

- Hose routing optimization

- Pressure & strength calculations

- Custom CAD drawings

- We provide end-to-end engineering solutions.

Applications

Industrial equipment manufacturing

Chemical & energy industries

Shipbuilding

Food and pharmaceutical plants

Automotive workshops and spray booths

Agriculture and irrigation

High-pressure cleaning

Firefighting systems

From gas and liquid transfer to high-pressure cleaning, we offer proven solutions across industries.

Machining of Industrial Hose Reel Components

Industrial stainless steel component machining requires a high level of precision, material expertise, and strict quality control to meet the demands of modern manufacturing. Stainless steel parts are widely used across industries such as automotive, energy, chemical processing, food equipment, medical devices, aerospace, and industrial machinery due to their excellent corrosion resistance, mechanical strength, and long service life.

Our stainless steel machining services cover a full range of components, including shafts, housings, brackets, flanges, fittings, valves, fasteners, and complex structural parts. We specialize in processing common grades such as SUS304, SUS316, 316L, 303, 410, and 420, ensuring optimal performance under high temperature, high pressure, and corrosive environments. Advanced CNC milling, turning, drilling, tapping, and multi-axis machining enable us to achieve tight tolerances, smooth surface finishes, and consistent dimensional accuracy.

various surface treatments, including polishing, passivation, sandblasting, and electro-polishing, to enhance appearance, cleanliness, and corrosion resistance according to application requirements.

Whether for prototype development or high-volume production, our stainless steel component machining solutions are designed to deliver reliability, durability, and cost efficiency. By combining experienced engineers, modern equipment, and a robust quality management system, we help customers transform designs into high-performance industrial parts that meet international standards and demanding operational conditions.

Finished products from industrial hose reel