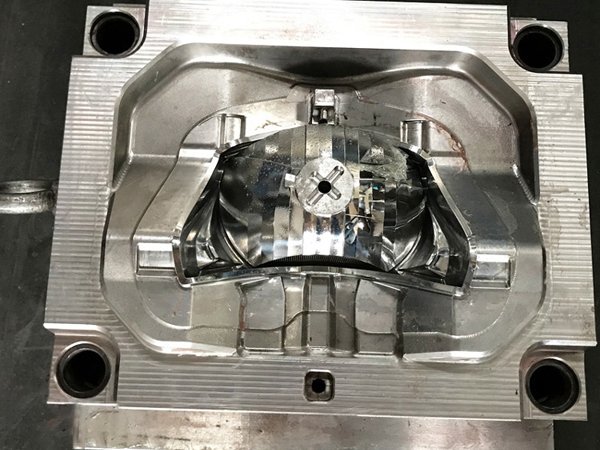

Injection Molded Plastic Parts

Custom plastic molded prototypes and production parts injection molding services for your. Get injection molded parts with impeccable quality, excellent finishes, and high dimensional stability at competitive prices.

- Rapid Tooling Production as fast as 2 weeks

- ISO 9001:2015 certified

- 24/7 engineering support

Our Injection Molding Capabilities

From plastic prototyping to production molding, CYCO’s custom injection molding service is ideal for the manufacturing of competitive pricing, high-quality molded parts in a fast lead time. Strong manufacturing facilities with powerful, precise machines ensure the same mold tool for creating consistent parts. Besides this, we offer a free consultation service on every order. Our expert will guide you on mold design, surface finishes selection, and convenient shipping methods.

Our designing and manufacturing experts manufacture top-notch economical custom injection molds using advanced equipment. We can manage different tolerances as per your demand.

To produce a standard quality thermoplastic part, our plastic injection molding process features precise machinery and operations to transform molten plastic resin into a tailored plastic part.

Our overmolding technique involves bonding plastics, metals, and rubber over each other with a resistant and durable chemical bond. With improved strength, we provided the fastest assembly time.

It is a custom injection molding process where thermoplastic is molded around the pre-built part, to produce a high-strength final product consists of multiple materials.

Advantages of Injection Molding

Injection molding is plastic manufacturing process that can produce high quality parts at scale. It’s typically used for low- to high-volume production but our aluminum tooling can also make prototyping runs economical.

- Low cost at higher volumes

- Exceptional part cosmetics and surface finish

- Repeatable

- Complex parts

- Low scrap rate

- Large selection of thermoplastic and thermoset materials

Injection Molding Applications

Injection molding is widely used for plastic part production in medical, consumer, and automotive industries. Typical parts include:

- Automotive

- Aerospace

- Consumer Goods

- Medical Devices

- Robotics

Injection material selection

Injection molding uses a wide variety of plastics and we offer a wide range of materials for our customers to choose from to ensure the best quality and performance of their products.

Impact resistant:

ABS, PMMA, PVC, PE, PC

Wear-resistant:

POM, PEEK, UHMW

Dimensional stability:

PBT, ABS, HIPS, PPS

Chemical resistance:

PEEK, PP, PBT, PA, PE, LDPE

Rubber like:

TPU, TPE, Silicone

Cost-efficient:

PP, HDPE, LDPE

Cosmetic:

ABS, PC, HIPS

Injection Molded Plastic Parts Gallery