Surface Treatment Services

CYCOSPRAY provides high quality surface treatment services to enhance the adaptability of parts to the environment and add aesthetic value to their appearance. Our first-class technology and specialized staff ensure that surface treatments are available to meet different needs.

Overview and Benefits of Surface Treatment

Surface treatment is the process of artificially forming a surface layer on the surface of a substrate material with mechanical, physical and chemical properties different from those of the substrate.

The purpose of surface treatment is to meet the corrosion resistance, wear resistance, decoration or other special functional requirements of the product.

Improved Look

Surface treatments can enhance the aesthetics of a product by customizing the appearance of the product with different colors, glosses and textures

Corrosion Resistance

Treated surfaces are more resistant to environmental aggressions such as humidity, acids and alkalis, which can greatly increase the durability and longevity of the product.

Increased Hardness

The hardness of a material can be increased by surface treatment, making it more resistant to wear. This is particularly important for items that are subject to constant friction and wear, such as machine parts and tools.

Improved Lubrication

Some surface treatments can improve the lubricating properties of materials, reduce friction, and improve the surface smoothness of workpieces, which reduces energy consumption and wear.

Enhanced Adhesion

Surface treatment improves the adhesion of substances such as coatings, paints or adhesives to the surface of the material and enhances their bonding to the substrate.

Anti Oxidization

For metal materials, surface treatment prevents oxidation, extends their life and maintains their properties.

Types Of Surface Treatment Offered By CYCOSPRAY

Additive Surface Treatment

Improving the surface properties of a workpiece by adding material. Typically used to repair and enhance the surface properties of components such as wear resistance, corrosion resistance and fatigue strength.

- Painting

- Powder Coating

- Anode Coating

- Electroplating

- Galvanizing

- Vacuum Metalizing

- Anodic Oxidation

- In Mold Decoration (IMD)

Subtractive Surface Treatment

Changing the surface characteristics of a workpiece by removing material. Typically used to improve the appearance, dimensional accuracy and surface quality of workpieces and to improve their wear, corrosion and fatigue resistance.

- Grinding

- Metal Wire Drawing

- Electropolishing

- Sand Blasting

- Photo Etching

- CNC Machining

Printing Surface Treatment

Post-processing of substrates such as paper, plastics, metals, and other materials after printing or imprinting to improve their appearance and functional properties.

- Screen Printing

- Pad Printing

- Hydro Transfer Printing

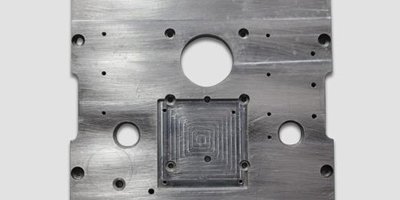

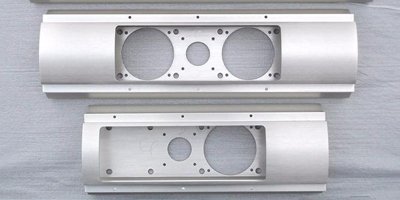

CYCOSPRAY Machining Surface Finishes Services

Surface Finishes can not only improve the appearance of CNC machined parts, but also increase the functionality of the internal parts, wear resistance and corrosion resistance, and extend the service life of the parts.

This finishing option has the shortest turnaround time. Parts have visible tool marks as well as potentially sharp edges and burrs that can be removed upon request.

Smooth machining is similar to last "As machined" finish, but machine marks are less obvious. Parts are machined at a lower feed speed without manual polishing.

The method of applying the grinding brush to the surface, it produces a uniform surface, but visible lines is its feature.

Materials: ABS,Aluminum,Brass,Stainless Steel,Steel

Parts are bead blasted with glass beads to produce a uniform grainy texture and reduce processing marks.

Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

The vibrating medium rolls over the machined part to remove sharp edges and burrs, and the roll can be used to remove machine marks on the outer surface. Materials: Aluminum, Stainless Steel, Steel, Brass, Copper

Bead blasting followed by anodizing (type II) matte surface finishing to create a uniform matte finish, the colors are naturally matte. It is ideal for improving corrosion resistance and aesthetics.

The material is brushed to form uniform oriented particles and then anodized to make it shiny. It forms a hard, wear-resistant oxide layer on the surface of the part to enhance its durability and corrosion resistance.

By anodizing the surface of a machined part for CNC milling, CNC turning, or 2-axis, 3-axis, or 5-axis CNC machining, a thick and durable oxide layer can be formed.

Through a chemical conversion process, metals such as aluminum and magnesium are coated with a thin protective film that gives excellent corrosion resistance and enhances the adhesion of subsequent coatings on CNC machined parts.

CYCOSPRAY Surface Treatment Technology (Take Galvanizing as an Example)

Cleaning: Use alkali or organic solvents to remove oil, grease and other impurities from the surface of the workpiece.

Acid washing: Remove surface rust and oxidized layers with an acid solution (e.g. sulfuric acid).

Neutralization: Remove residual acid with a neutralizing solution and flush well.

Water Rinsing: Multiple water rinses to ensure that the surface of the workpiece is clean and free of residue.

The workpiece is placed as a cathode in a tank containing a zinc salt solution.

A pure zinc plate is added at the anode while a direct current is applied.

Zinc ions migrate from the anode to the cathode under the action of the electric field and are reduced to metal zinc on the surface of the workpiece, forming a uniform zinc coating.

Passivation: It increases the corrosion resistance of the zinc coating.

Inspection: The thickness, appearance and performance of the coating are checked.

Why Choose CYCO as Your Partner

Quality Assurance

We strictly comply with industry standards and norms to ensure that the surface finish of each product meets the highest quality requirements. We have a well-established quality management system with strict quality control measures in every step of the process, from raw material procurement to final delivery.

Customized Services

Depending on your specific needs and application environment, we can provide personalized surface treatment solutions. Our technical team will work closely with you to ensure that all your needs and expectations are met.

Wide Range of Services

We offer a wide range of surface treatment techniques such as electroplating, painting, anodizing, and more. Whether you need a basic anti-corrosion treatment or an advanced decorative effect, we are able to fulfill it.

Fast Delivery

With our efficient production line and professional logistics system, we can ensure that your orders are completed in time and delivered on time. We understand that time is important to you, so we will do our best to shorten the delivery cycle to meet your urgent needs.

Expertise and Experience

With many years of experience and expertise in surface treatment, we are able to provide the best surface solutions for your products. Our team consists of industry experts who constantly keep track of the latest technological developments to ensure that our services remain at the forefront of the industry.

Honest Customer Service

We emphasize communication and service with our customers and provide 24/7 customer service support. We will follow up your feedback and suggestions on a regular basis to continuously improve our service quality and efficiency.