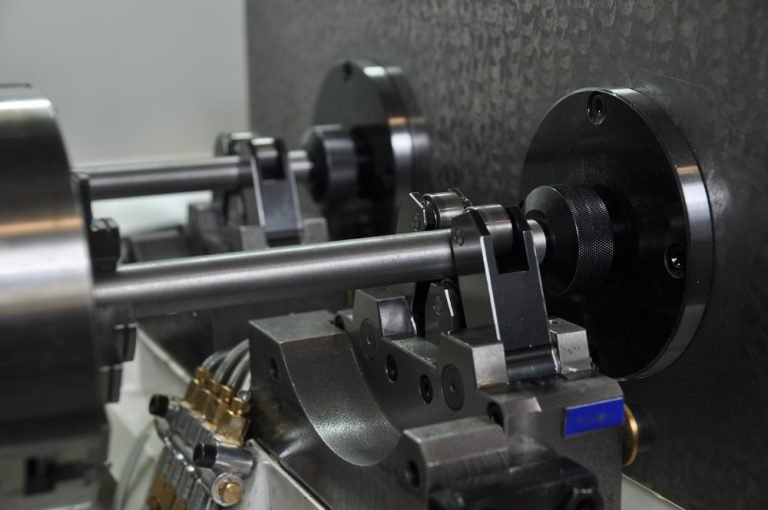

Main Errors in CNC Machine Tool Machining:

1. Dimensional Errors: These errors occur when the machined part does not meet the specified dimensions. They can be caused by factors such as tool wear, thermal expansion, and machine calibration issues.

Improvement methods:

– Regularly inspect and replace worn tools to ensure accurate machining.

– Implement temperature control measures, such as temperature compensation or thermal stabilization of the machine, to minimize thermal effects.

– Conduct regular calibration and maintenance of the machine to ensure accurate positioning and motion control.

2. Surface Finish Errors: These errors manifest as rough or uneven surface finishes on the machined part. They can result from factors such as improper tool selection, incorrect cutting parameters, or vibration in the machine.

Improvement methods:

– Use appropriate cutting tools and optimize their geometry for the specific machining task.

– Adjust cutting parameters such as feed rate, spindle speed, and depth of cut to achieve the desired surface finish.

– Reduce or eliminate machine vibration through proper machine setup, damping techniques, or dynamic balancing of rotating parts.

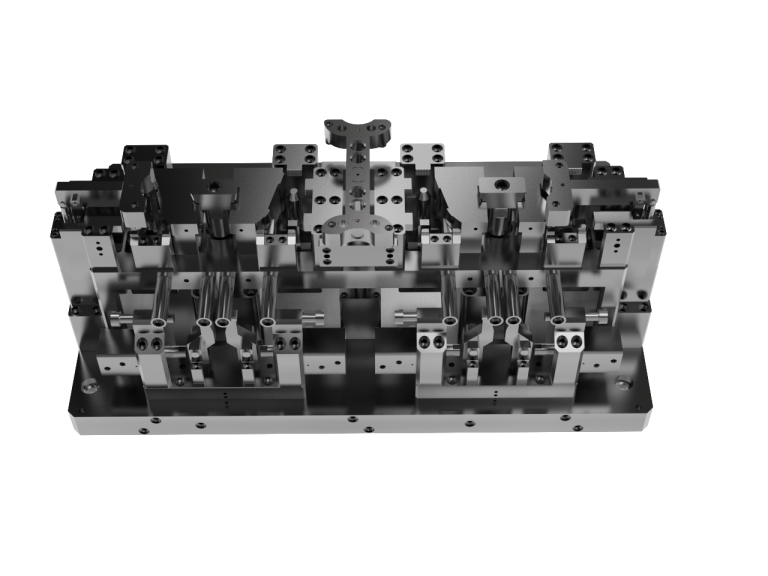

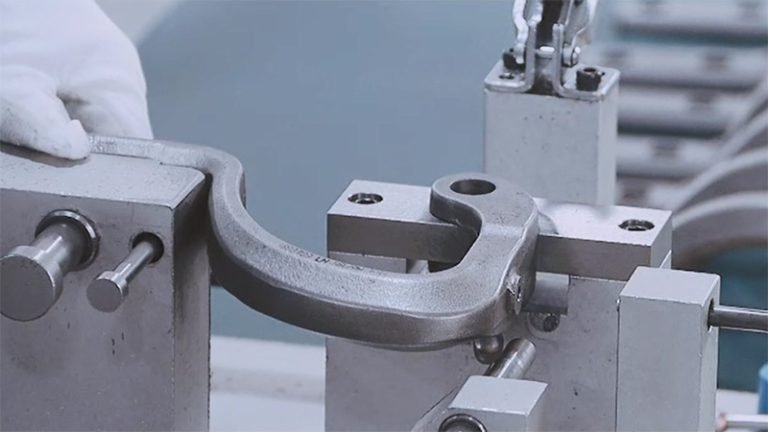

3. Geometric Errors: Geometric errors refer to deviations from the desired geometric shape or form of the machined part. They can be caused by factors such as machine backlash, geometric inaccuracies in the machine structure, or misalignment of the workpiece.

Improvement methods:

– Implement compensation techniques, such as backlash compensation, to minimize the impact of machine errors on part geometry.

– Conduct regular checks and adjustments to ensure proper alignment of the machine components.

– Use precision fixtures and workholding techniques to minimize workpiece misalignment.

4. Tool Path Errors: These errors occur when the actual tool path deviates from the programmed tool path. They can result from issues such as machine positioning errors, incorrect tool offsets, or programming errors.

Improvement methods:

– Verify and validate tool paths using simulation or verification software before machining.

– Regularly calibrate machine positioning systems to ensure accurate tool path execution.

– Double-check tool offsets and make necessary adjustments to match the intended tool path.

By addressing these common errors and implementing the suggested improvement methods, CNC machine tool machining can achieve higher precision, better surface finish, and improved overall part quality.