The diversity of machining processes requires materials that can perform optimally in different conditions. One material that fits the bill is polyetheretherketone (PEEK), which is not only a lightweight polymer, but also has good properties over a wide range of temperatures.

Read more to learn something about PEEK.

What is PEEK?

Polyetheretherketone, known as PEEK for short, is a polymer belonging to the Polyaryletherketone (PAEK) family.PEEK is a colorless organic thermoplastic polymer that is typically manufactured by stepped polymerization.

It has excellent abrasion resistance, so it is popular in several areas of engineering, making it suitable for a wide range of engineering applications.

Compared to other polymers, PEEK is more expensive, but offers excellent performance in a number of areas.

Properties of PEEK

-

High temperature resistance

An advanced thermoplastic material that is resistant to high temperatures.

Thanks to its high heat resistance as well as thermal conductivity, PEEK maintains its high strength even at very high temperatures. It can withstand short-term operating temperatures of up to 300°C and continuous operating temperatures of up to 250°C, which is one of the reasons why PEEK materials can be used in places where heat resistance is a concern. -

Good mechanical properties

The best fatigue resistance of all resins. The combination of its excellent mechanical properties and fatigue resistance is one of the more outstanding of all plastics and is no worse than some alloys.

-

Excellent wear resistance and lubricity

PEEK and its composite materials have excellent wear resistance, some PEEK has a extremely low friction coefficient.

PEEK has excellent sliding characteristics, especially in bearing applications. Its inherent lubricity greatly reduces the friction coefficient, allowing some parts to operate without lubricants, as well as in media such as water, weak acids and alkalis. -

Chemical resistance

Stable chemical resistance. Chemically resistant to acids, alkalis, organic solvents and other chemicals as well as various gases.

-

Corrosion resistance

Usually refers to the ability of a metal to resist corrosion and damage from surrounding media.

The material composition, chemical properties, organization and morphology of PEEK determine its corrosion resistance, which is similar to that of nickel steel. -

Flame retardant

A linear aromatic semi-crystalline polymer with its own flame retardant properties. UL94 testing has demonstrated that its burning rate in samples without any additives is V-0, which is the highest level of flame retardancy, so PEEK can be used in building materials, vehicles and appliances where high flame retardancy is required.

-

Peel resistance

PEEK has good peel resistance. It can be used to make thinly wrapped wire and cable insulation, allowing them to be used in harsh environments and conditions.

-

Radiation resistance

PEEK material maintains its original properties under gamma radiation, which is better than polystyrene (PS).

-

Hydrolysis resistance

PEEK and its composites are not subject to the chemical effects of water and high-pressure water vapor. Products made of this material maintain excellent performance when used continuously in high-temperature and high-pressure water.

Types of PEEK machining

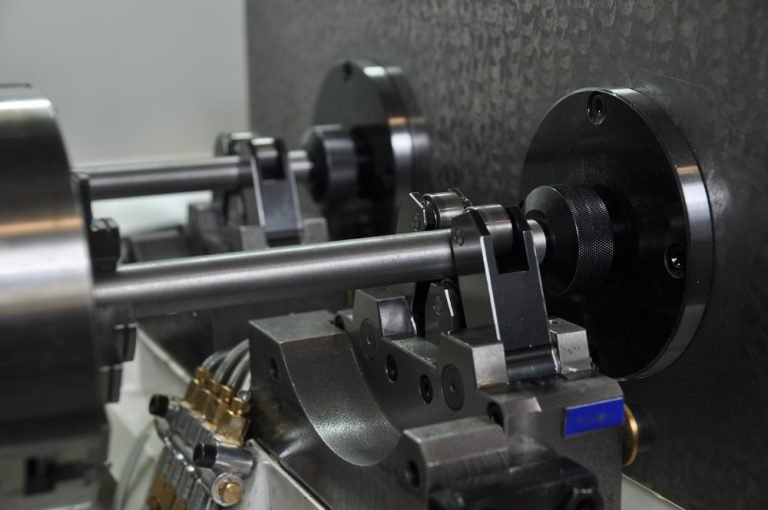

CNC machining of PEEK

CNC machining consists of different variants of multi-axis milling, turning and electric discharge machining (EDM) to obtain the desired geometric profile. The main advantage of these machines is the ability to control the machine through computer-generated codes.

CNC machining offers the opportunity to create complex geometries in a variety of materials, from plastics to metals, while meeting the limits of geometric tolerances.

However, there are still some issues to be aware of in PEEK CNC machining.

-

High temperatures and stress

To prevent surface cracks and internal stresses due to heat generated during the cutting process, PEEK rods need to be annealed before machining. This process is used to release tension and reduce the possibility of distortion. Depending on the time required for machining, multiple annealing programs may be required, such as an initial annealing before rough machining and a subsequent annealing before finishing to avoid cracking.

-

Tool wear

Medical grade PEEK typically contains stiffer carbon fibers, so softening the PEEK material prior to machining is required to avoid tool wear.

-

Tool material

When working with natural PEEK, cutting tools are usually recommended to consist of silicon carbide. If carbon fiber reinforcement is present or very tight tolerances are required, diamond tools are the best choice. In addition, the use of pure water as a coolant during machining is essential to eliminate the cutting heat generated.

-

Drilling holes

The low elongation of PEEK compared to other polymers can lead to cracking when drilling deep holes.

-

Coolant

Since PEEK does not dissipate heat, it tends to deform or break during machining, so it needs to be cooled.

PEEK 3D Printing

3D printing, also known as additive manufacturing, is a technology that uses a digital model file as the basis for constructing an object by printing layer by layer using a bondable material such as powdered metal or plastic.

Fused deposition modeling (FDM) is the most widely used method of 3D printing with PEEK materials.

3D printed PEEK products have good wear resistance. Fibers from different manufacturers can offer different properties, such as producing customized implants to meet individual patient needs or for use in different space systems.

However, to print PEEK materials, besides a high-temperature nozzle with an operating temperature of more than 300°C, a heated bed is required to continuously keep the material heated. Some printers also use heated chambers for this purpose, which allow for better control of the room temperature and provide continuous heat.

PEEK Injection Molding

Thermoplastic parts are manufactured by injecting molten material into an existing mold for high volume manufacturing of parts.

Pelleted PEEK materials are used for injection and compression molding. Pelleted PEEK from different manufacturers requires slightly different drying procedures, but typically 3 to 4 hours at 150 °C to 160 °C is sufficient.

However, cooling of the molds requires special attention, as it may lead to structural changes in the PEEK material. For example, the use of cold molds can lead to the creation of amorphous structures in PEEK.

The optimum working temperature for most grades of PEEK is considered to be between 170°C and 200°C to obtain a semi-crystalline structure.

Applications for PEEK machining

There are a variety of uses for this material, such as automotive, electrical and electronics, aerospace, medical and food processing.

Industrial grade PEEK plastics are commonly used in the aerospace, automotive, chemical, electronics and energy industries, while medical grade PEEK plastics are more suitable for healthcare and dental applications.

-

Medical

Due to the biocompatibility of PEEK materials, they are used in a wide range of medical applications, which also include the implantation of components into the human body. Components made from PEEK are also used in different drug delivery systems. Other medical applications include dental healing caps, tip gaskets, trauma immobilization devices and spinal fusion devices.

-

Aerospace

Parts made from PEEK plastic are widely used in aerospace applications due to its compatibility with ultra-high vacuum applications, high tensile strength, thermal conductivity, radiation resistance and chemical resistance.

-

Automotive

bearings and different types of rings are also made from PEEK. Because of its excellent weight-to-strength ratio, PEEK is used to make parts for engine blocks in race cars.

-

Wire and cable insulation/electronic applications

Cable insulation is made of PEEK and is used in manufacturing projects for applications such as aircraft electrical systems.

Conclusion

As a semi-crystalline organic polymer, PEEK has excellent mechanical, chemical and electrical properties, making it the material of choice for several engineering applications.

In addition, PEEK is available in various forms, such as rods, filaments and pellets, and can be machined through CNC machining, 3D printing and injection molding.

PEEK CNC Machining FAQs

What are the causes of deformation in PEEK CNC machining?

- 1. Internal stresses in the material are either not completely removed or the annealing process is not performed.

- 2. The depth of cut has been set too deep.

- 3. Coolant is not used to dissipate the heat generated by the cut.

- 4. The cutting process is irregular and uneven, resulting in more cuts on one side than the other.

- 5. Vibration occurs in weak fixtures that do not hold the workpiece securely.

- 6. Fixtures are too tight.

How to find a reliable CNC machining service provider?

At CYCO, we offer CNC PEEK plastic machining services including milling and turning. Whether you need a prototype component or a high-volume production run, our goal is to provide high-quality PEEK parts with low cost and high efficiency.

Our CNC machining service specialists are available to answer any questions you may have about your PEEK project, and we offer free advice on design and material machining based on our experience.

Please feel free to contact us and work with us without hesitation.