What is 3D printing?

3D printing is a rapid manufacturing technology and a revolutionary manufacturing method, also known as Additive Manufacturing (AM), which allows digital designs to be transformed into physical objects by creating three-dimensional solids made by stacking materials layer by layer.

The process of 3D printing starts with the design of a three-dimensional model through a computer-aided design software such as CAD and then cuts the model into several layers.

During the printing process, a material is selected to be stacked layer by layer such as plastic, metal or biomaterials. With precise control from the computer, each layer builds on the previous one.

This precise layer-by-layer building method allows for the printing of virtually any shape and structure, from prototypes to custom products and even complex engineering parts, without the need for molds or cutting tools used in traditional manufacturing methods.

What materials can 3D printing work with?

- Plastics: such as ABS, PLA, PETG, Nylon, TPU, PVA, HIPS and more.

- Metals: stainless steel, aluminum alloy, titanium alloy, nickel alloy, copper alloy and others.

- Ceramics: alumina, silicon nitride, zirconia, silicon carbide.

- Biomaterials: bioprinting ink, cellular material, bioceramics, biopolymers.

- Composite materials: carbon fiber reinforced plastics, glass fiber reinforced plastics, metal composites.

- Food materials: chocolate, candy, dough.

- Other materials: plaster, paper, wood, wax.

Pros and cons of 3D printing

Pros

- 1. Higher degree of free design which allows for the manufacture of complex products and components.

- 2. Can quickly produce a prototype of the product to reduce the development cycle.

- 3. Suitable for small batch production and can meet the individual needs of customers.

- 4. No need for machining or any molds, it can create any shape of parts directly from computer graphic data, which saves the cost and time of mold manufacturing.

Cons

- 1. Less efficient than traditional manufacturing technologies in mass production.

- 2. Lower surface quality of products manufactured by some 3D printing technologies.

- 3. Different 3D printing materials have different performance characteristics, including strength and heat resistance, and need to be selected according to specific needs.

- 4. The investment cost of 3D printing machines is high, and the high cost of particular 3D printing materials may increase the manufacturing cost of the products.

What are the methods of 3D printing?

There are several different 3D printing methods on the market today, each with their own unique strengths and weaknesses for different applications.

Here are a few of the main 3D printing methods and their characteristics:

Fused Deposition Modeling – FDM

A common 3D printing technique and one of the first additive manufacturing methods.

In the FDM process, a hot nozzle stacks layers of molten thermoplastic material on top of each other to gradually build the desired three-dimensional object.

Here are the pros and cons about FDM:

Pros

-

Low cost

FDM printers are usually relatively inexpensive and suitable for individual users, educational institutions and small businesses, which greatly lowers the barrier to entry into the 3D printing field.

-

Material versatility

FDM supports many different types of molten plastic materials, including PLA, ABS, PETG, TPU and more, which means that the right material can be selected depending on the requirements of the project.

-

Large sizes

FDM printers are also suitable for manufacturing larger objects, as they typically have a larger printing machine bed.

-

Simple to use

FDM technology is easy to use, making it a good choice for beginners. Most FDM printers offer user-friendly interfaces and software.

-

Open source community

FDM technology is very popular in the open source community, which means that there is a large amount of open source software and teams that are constantly improving and developing FDM printers.

Cons

-

Poorer surface quality

Parts printed by FDM usually have visible traces of layering and the surface quality is not as good as some other 3D printing.

-

Lower speed

Especially for large objects, FDM printing takes longer because it is a layer-by-layer stacking process.

-

Require support structure

In FDM, some parts require support structures to prevent sagging or warping. These supports need to be removed at a later stage, which adds extra work.

-

Limited to molten plastics

Compared to some other 3D printing technologies such as SLS or SLA, FDM technology is limited by the materials available and may not be suitable enough for some specific applications.

-

Limited precision

The accuracy of FDM printing is usually low, making it unsuitable for applications that require a high degree of precision.

Stereolithography – SLA

A common high-precision and high-resolution 3D printing technology that uses UV light beams to cure liquid photosensitive resins layer by layer to build complex three-dimensional objects.

Here are more details about SLA technology, including its benefits and limitations:

Benefits

-

High precision

SLA printers typically have very high resolution, allowing for very fine details and complex geometries. This makes SLA suitable for applications that require high precision, such as jewelry, model making, and the medical field.

-

Smooth surfaces

Due to the light-curing process, SLA prints usually have a very smooth surface, often requiring no additional surface preparation or sandpaper sanding.

-

Support a wide range of materials

SLA can use many different types of photosensitive resin materials, including transparent, soft, heat-resistant and other resins with different properties, allowing it to meet the needs of different projects.

-

Fast printing speed

Compared to other 3D printing technologies, SLA typically has a faster print speed because it can cure multiple parts in one layer at the same time.

-

Suitable for small and precision parts

SLA is suitable for manufacturing small and precision parts such as micro devices, prototypes, molds and micro tools.

Limitations

-

Limited material options

Although SLA offers a wide range of photosensitive resin materials, its material options are still relatively limited compared to technologies such as FDM.

-

UV sensitivity

SLA uses a UV light beam to cure the resin, which means that safety precautions need to be taken during the work process to avoid skin and eye damage.

-

Post-processing

While SLA printing typically has a smooth surface quality, some post-processing may still be required, such as cleaning to remove residual resin and support structures.

-

Build volume limitations

SLA printers typically have a small build volume, which limits the size of objects that can be printed.

Overall, SLA is a 3D printing technology that is well suited for applications that require high precision and high surface quality. It has a wide range of applications in many fields such as medical, jewelry design, prototyping, and engineering.

Selective Laser Sintering – SLS

An advanced 3D printing technology that uses a laser beam to sinter powdered materials layer by layer to build three-dimensional objects.SLS also has some significant merits and restrictions:

Merits

-

Material versatility

SLS can work with many different types of powder materials, including plastics (e.g., nylon, polyamide), metals (e.g., aluminum, titanium), ceramics, and more. This multi-material support makes SLS suitable for a wide range of applications.

-

No support required

SLS does not require support structures because prints are cured in a bed of powder, which means there is no need to manually add or remove support structures, which reduces post-processing work.

-

High strength and heat resistance

Parts printed by SLS typically have high strength and heat resistance, making them suitable for applications that need to withstand high loads or high-temperature environments.

-

Suitable for complex geometries

SLS technology can create complex geometries and internal structures, which is great for creating customized parts and functional prototypes.

-

High accuracy

SLS printing is often highly accurate, especially for small parts and details.

Restrictions

-

High equipment and material costs

SLS printers and powder materials are usually quite expensive.

-

Handling and recycling of powder materials

Special equipment is required to handle SLS powder materials, while recycling and reusing powder materials is relatively complex and may require additional labor and costs.

-

Surface quality is not as good as SLA

Despite its high precision, the surface quality of SLS is usually not as good as that of SLA, so some surface preparation work is required.

-

Dust and safety issues

SLS uses powdered materials and requires special safety measures to deal with dust and lasers to ensure operator safety.

Overall, SLS is a very powerful 3D printing technology that is particularly suited to applications requiring high strength, high precision and complex geometries, such as aerospace, medical devices, automotive manufacturing and engineering.

However, its cost and operational complexity may limit its widespread use in certain applications.

The choice of 3D printing technology requires careful consideration based on the needs, budget and material selection of a specific project.

Digital Light Processing – DLP

A high-precision 3D printing technology that uses digital projectors and UV photosensitive resins to build three-dimensional objects, DLP technology has a wide range of applications in several fields.

Below are detailed information about DLP, including its advantages and disadvantages:

Advantages

-

High speed printing

DLP printing is often very fast because entire layers can be cured at one time without the need for point-by-point or line-by-line builds, making it suitable for mass production and projects with tight production cycles.

-

High accuracy

DLP technology is typically characterized by high precision, allowing for the creation of detailed parts and objects with smooth surfaces. Because there are no moving beams or movable printheads, vibration deviations are small and there are no material blockage problems.

-

Good surface quality

Because the entire layer is cured at once, DLP-printed objects usually have smooth surfaces, eliminating the need for additional surface treatments.

-

Suitable for large objects

DLP printers are suitable for creating larger print objects.

-

Multi-material support

DLP can be used with many different types of photosensitive resin materials, including transparent, soft, rigid, and other resins with different properties, thus meeting the needs of different projects.

Disadvantages

-

Limited material options

Although DLP offers a wide range of photosensitive resin materials, its material options are still relatively limited compared to some other 3D printing technologies.

-

Limited life of light source

DLP printers use UV lamps to cure the resin, but these lamps have a lifespan and need to be replaced periodically.

-

Limited to photosensitive resins

DLP technology is limited to photosensitive resin materials, so it is not suitable for all types of projects, such as metal or ceramic printing.

-

Dust and safety issues

DLP technology uses photosensitive resin materials and requires special safety measures for handling materials and equipment to ensure operator safety.

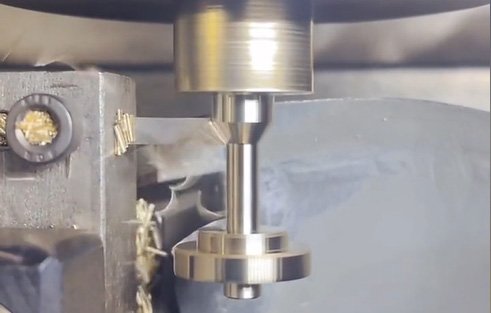

Metal 3D Printing, such as Direct Metal Laser Sintering – DMLS

Metal 3D printing is an advanced additive manufacturing technology that uses high-energy laser beams or electron beams to melt metal materials after stacking metal powders or wires layer by layer to build metal parts.

This technology has a wide range of applications in a variety of fields, including aerospace, automotive manufacturing, medical devices, engineering and manufacturing.

Benefits

-

High strength and durability

Parts made by metal 3D printing are typically high strength, hardness, and heat resistance, making them suitable for applications that need to withstand high loads and high-temperature environments.

-

High precision

Able to create complex metal parts and details.

-

Complex geometry

Metal 3D printing technology can create parts with complex internal structures and geometries that cannot be easily achieved with traditional machining methods.

-

Customized manufacturing

Metal 3D printing allows for the manufacturing of personalized and customized metal parts for medical implants, aerospace components, and more.

Drawbacks

-

High cost of equipment and materials

Metal 3D printers and metal powders or wires are usually very expensive.

-

Slow build speed

Metal 3D printing is usually slow to build compared to other 3D printing technologies because it involves a complex process of melting metal.

-

Limited material options

Despite the wide range of metal materials available, material options are still relatively limited compared to traditional materials such as steel and aluminum alloys.

Conclusion

Overall, 3D printing is a promising technology that is changing the way we produce. With the advancement of the technology and the expansion of its applications, we can expect it to overcome the current challenges and achieve wider applications, driving the progress and development of the manufacturing industry.

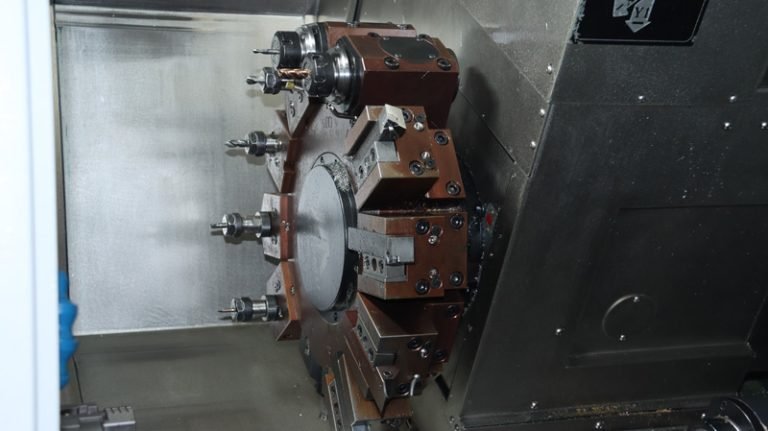

Despite the challenges of cost, speed, and material selection with 3D printing technology, CYCO has over two decades of experience in manufacturing and machining to help solve your problems.

If you need efficient and quality CNC machining manufacturing services, choose CYCO and we will provide you with the best quality service.

Now, contact us for an instant quote and work with us for a worry-free experience.