CNC machining is a manufacturing process that involves the use of computer-controlled machines to produce precise and complex parts and components. The term “CNC” stands for Computer Numerical Control, which refers to the use of computer programs to control the movement and operation of the machines.

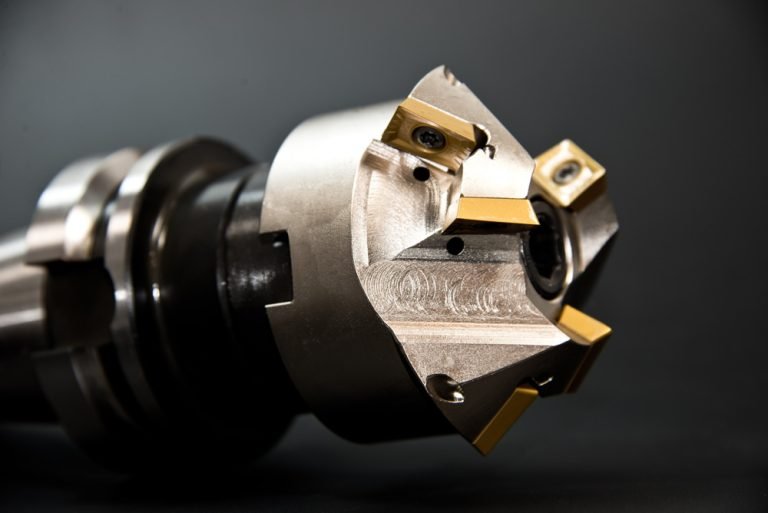

In CNC machining, a computer program is used to control the movement of cutting tools and other machinery, such as lathes, mills, routers, and grinders. The program provides instructions for the machine to follow, including the speed, direction, and depth of the cuts.

CNC machining is widely used in various industries, including aerospace, automotive, medical, and electronics. It is particularly useful for producing parts and components with complex shapes and tight tolerances, as the computer-controlled machines can perform precise and repeatable operations with high accuracy.

One of the key advantages of CNC machining is its ability to automate the manufacturing process, which can lead to increased efficiency, reduced costs, and improved quality control. CNC machines can also be programmed to produce parts in large quantities, making it an ideal solution for mass production.

CNC machining is a versatile and efficient manufacturing process that has revolutionized the way parts and components are produced. Its ability to produce complex shapes and tight tolerances with high accuracy has made it an essential tool in modern manufacturing.