Although a burr may be small, its impact should not be underestimated, keep reading and explore with us to learn more about burrs.

What is a Burr?

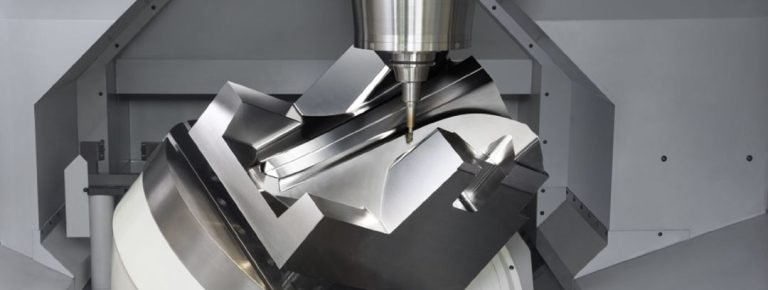

In the field of metal fabrication, a burr is excess material that is created on the edge or inside of a workpiece during machining processes such as cutting, stamping, drilling, milling, etc. The burr will still be attached to the workpiece after the machining is completed.It is a natural result of removing material from a workpiece during metal fabrication due to localized plastic deformation, fracture and splash effects caused by the relative motion between the tool and the workpiece during metal cutting. It is a localized plastic deformation, fracture and splash effect due to the relative motion between the tool and the workpiece during metal cutting. These excess materials exist in various shapes and sizes, such as sharp spikes, raised bits or irregular pieces. Their presence is usually undesirable as they can affect the quality and functionality of the final product.

For this reason, deburring is an important post-processing step, and manufacturers often employ additional processes to remove these unwanted edges and ensure that the final product meets quality standards. Deburring techniques include manual methods, abrasive tools, or specialized deburring machines, and the choice depends on factors such as the specific workpiece material, construction, burr size, and productivity requirements.

Why do burrs occur?

Burrs are a natural result of various material removal techniques during metal fabrication. Factors such as tool geometry, cutting speed and the type of material being machined all affect the size and shape of the burr. The formation of a burr is influenced by a combination of factors, and understanding these factors can minimize or prevent burr generation.

The following are some of the main causes of burr formation:

Cutting tools

The design and condition of the tool has a significant impact on burr formation. Cutting tools can become dull or worn after a long period of time, which can lead to poor cutting results and burrs. In addition, the rake angle, clearance angle and sharpness of the cutting edge all affect the quality of the cut and the presence of burrs. What’s more, the material of the tool can also have an effect; for example, tools with coatings can reduce burr generation.

Material to be machined

The type of material being machined can affect the formation of burrs, some materials are more prone to burr formation than others. For example, brittle materials such as cast iron may produce more pronounced burrs than softer materials. Burrs may also be more likely to form if there is a large difference in hardness between the workpiece material and the tool. In addition, thicker materials may be more susceptible to burr formation, especially if the tool is not able to effectively handle a particular thickness of material.

Improper machining

The parameters and sequence of machining can also have a significant impact on burr formation. The speed at which the cutting tool moves through the material can affect burr formation, and high cutting speeds may increase the potential for burr formation, especially if the cutting tool is not properly designed or maintained. Also, the speed at which the workpiece is fed into the cutting tool can have an effect. High feed rates can lead to burr formation, especially if the cutting tool is unable to adequately handle material removal. In some cases, the choice of machining sequence can have a significant impact on the final burr formation.

Therefore, it is critical to select the correct cutting speed, feed rate and machining sequence.

Equipment

Accuracy errors present in the machine itself can also affect the quality of machining and lead to burr generation. The condition of the machining equipment, including the rigidity and accuracy of the machine tool, can affect burr formation. Vibrations and deviations in the machine can lead to irregular cuts and burr formation.

Understanding and controlling these factors is an important part of producing a high quality product. Burr formation can be effectively reduced by optimizing processes, selecting appropriate tools and materials, and improving operator skills.

Why deburring?

The presence of burrs not only affects the quality of the appearance of the workpiece, but can also have an adverse effect on the assembly performance, safety in use and service life of the product. For example, in the case of precision equipment, burrs can affect its function and accuracy.

The importance of deburring is mainly reflected in:

- Improve safety: Burrs can be sharp and pose a safety hazard to workers. In addition, oversized burrs can cause interference during assembly or even lead to injuries to the user in severe cases. Removing burrs reduces the risk of cuts and injuries.

- Increase accuracy: Burrs can affect the positioning, clamping and dimensional control of workpieces during subsequent machining, thus affecting the accuracy of the final product. Removing burrs ensures that the product meets specific quality standards and specifications.

- Better appearance: A burr-free product has a better visual appearance, allowing for better paint adhesion and a more uniform coating. For industries where appearance is important, burrs can make a product look unprofessional, and removing them can result in a more aesthetically pleasing product with a better quality appearance.

- Reduce friction: Burrs increase friction between parts, long-term wear and tear will reduce the overall performance of the machine. Removing burrs not only improves the life and efficiency of mechanical components, it also ensures that parts fit together as intended.

- Lower costs: Although deburring requires additional machining, burr-free products need less maintenance in the long run, which helps reduce overall operating costs.

- …

How to deburr?

There are many ways to deburr, and the choice depends on factors such as the material of the workpiece, the geometry and size of the part, and the required accuracy.

The following are a few common deburring methods:

Manual deburring

The use of files, sandpaper, polishing wheels and other tools for manual grinding and cleaning, files are divided into hand files and pneumatic files. This method is not very efficient and is suitable for small-scale production, but can be used with any other method to achieve better results.

Chemical deburring

Selective dissolution of burrs on metal surfaces through chemical reactions, such as electrolytic deburring or acid washing. It does not affect the entire part and is suitable for complex parts that are difficult to handle by mechanical methods.

Mechanical deburring

Utilize a variety of mechanical equipment to remove burrs, such as vibratory grinders, drum deburring machines, rotating brush discs, etc.

- Grinding: a commonly used mechanical deburring method, using grinding tools with particles on the surface of the workpiece for friction and impact, with the aim of removing burrs. This type of deburring method has more applications and is suitable for small parts in large batches.

- Tumbling: parts can be placed in a tumbler with the abrasive media. The tumbling action helps in removing burrs and smoothing the edges. This method is suitable for the batch production of small parts.

- Brushing: the surface of the workpiece is rubbed and impacted using a high speed rotating brush disk to remove burrs. This method is suitable for deburring various metals, plastics and other materials.

- Sandblasting: use compressed air to push abrasive particles into the workpiece. This process effectively removes burrs and provides a consistent surface finish. It is commonly used for metal parts.

Freeze deburring

The surface of the workpiece is rapidly cooled by refrigeration technology to form a brittle layer, and then impacted to dislodge it.

Thermal deburring

The use of high temperature to vaporize the burr instantly, for instance, electrochemical deburring and laser deburring.

- Electrochemical: utilizes an electric current to selectively deburr metal parts. It is very effective on precision parts.

- Laser: removes burrs by melting or vaporizing excess material.

High pressure water jet deburring

High pressure water is used as a medium and its instantaneous impact is utilized to remove burrs and flying edges generated after machining, while cleaning can be achieved at the same time. This method is suitable for heat-sensitive materials.

Ultrasonic deburring

The use of ultrasonic vibration makes the surface of the workpiece to produce tiny bubbles rupture in order to break the burr. Mainly for some microscopic burrs, if the burrs need to be observed with a microscope, you can try to remove them with ultrasonic methods. This method is suitable for complex small parts.

Magnetic deburring

Use the force of magnetic field to attract and repel metal chips to achieve the purpose of deburring.

The choice of deburring method depends on factors such as material, part complexity, throughput and desired finish. In many cases, a combination of methods can be used to achieve optimum results. In addition, the specific requirements of the end product must be considered to ensure that the deburring process does not affect the function or appearance of the part.

Summary

Burrs are a natural result, but understanding the causes of burrs can greatly help us to avoid them. For higher part requirements, there are many ways to remove burrs. Deburring is an important part of improving the accuracy of a part, and it also enhances the performance of the part.

CYCO, with more than 20 years of experience in precision machining, has a solution for every cause of burr. We have advanced technology, precision equipment and specialized staff to ensure that we produce high quality products with no or very few burrs, which can greatly improve the quality of your parts and save you time and cost.

If you need to deburr your products or need to produce high quality products without burrs, we will provide you with the most effective and cost-efficient solutions, feel free to contact us.