Forging machining is a vital manufacturing process that has been utilized for centuries to create strong, durable metal components. This process involves the shaping of metal through the application of compressive forces, resulting in a finished product with enhanced mechanical properties and structural integrity. In this article, we will delve into the various forging techniques, their applications, and the advantages of forging machining over other manufacturing methods.

Forging Techniques

There are several forging techniques, each with its unique characteristics and applications. The most common methods include:

1. Open-die forging: Also known as free forging, this technique involves the shaping of metal between two flat or contoured dies without completely enclosing the workpiece. The metal is heated and then hammered or pressed into the desired shape. Open-die forging is ideal for producing large, simple components such as shafts, bars, and rings.

2. Closed-die forging: In this method, the metal is placed between two dies that have a pre-formed cavity, which closely resembles the final shape of the component. The dies are then closed, and the metal is forced to fill the cavity, taking on the desired shape. Closed-die forging is suitable for producing complex components with tight tolerances and minimal machining requirements.

3. Upset forging: This technique involves increasing the diameter of a metal workpiece by compressing its length. Upset forging is commonly used to create heads on bolts, screws, and other fasteners.

4. Roll forging: In roll forging, the metal workpiece is passed through a series of rollers that progressively shape it into the desired form. This method is particularly useful for producing long, slender components such as axles and leaf springs.

5. Press forging: Press forging uses a hydraulic or mechanical press to apply a slow, continuous force to the metal workpiece, shaping it into the desired form. This technique offers greater control over the forging process and is ideal for producing components with intricate shapes and tight tolerances.

The Forging Process:

The forging process in forging machining typically involves four main stages:

1. Heating: The metal is heated to a specific temperature to enhance its malleability and make it easier to shape.

2. Deformation: The heated metal is subjected to compressive forces through various methods, such as hammering, pressing, or rolling. This process alters the metal’s shape without compromising its integrity.

3. Trimming and Piercing: Excess material is removed, and necessary holes or features are created through secondary machining operations.

4. Heat Treatment: The forged part undergoes heat treatment processes like annealing, quenching, or tempering to optimize its mechanical properties.

Applications of Forging Machining

Forging machining is employed across a wide range of industries due to its ability to produce strong, durable components. Some of the most common applications include:

1. Automotive: Forged components are widely used in the automotive industry, particularly in the production of engine and suspension components, such as connecting rods, crankshafts, and steering knuckles. These parts require high strength and durability to withstand the stresses and strains of daily use.

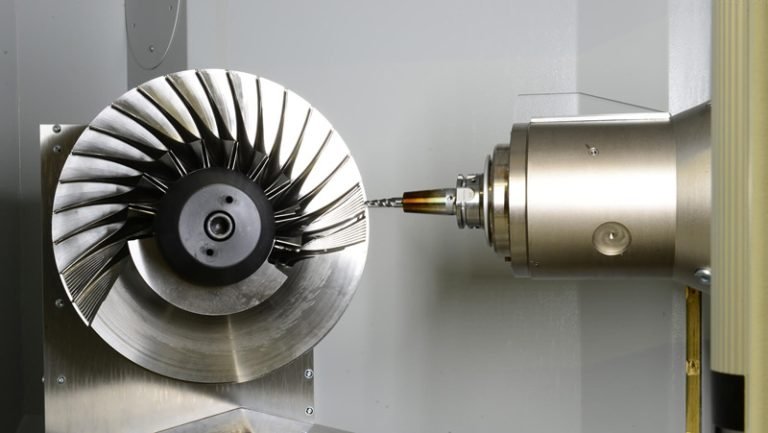

2. Aerospace: The aerospace industry relies on forged components for their exceptional strength-to-weight ratio. Forged parts are used in the production of aircraft engines, landing gear, and structural components.

3. Oil and gas: Forged components are essential in the oil and gas industry, where they are used to create high-pressure valves, fittings, and other equipment that must withstand extreme pressures and temperatures.

4. Construction: Forged parts are used in the construction of heavy machinery and equipment, such as cranes, bulldozers, and excavators. These components must be able to withstand the rigors of heavy-duty use and harsh environments.

5. Agriculture: Forged components are used in the production of agricultural machinery and equipment, such as tractors, plows, and harvesters. These parts must be durable and able to withstand the wear and tear of daily use.

Advantages of Forging Machining

Forging machining offers several advantages over other manufacturing methods, including:

1. Improved mechanical properties: The forging process aligns the grain structure of the metal, resulting in improved strength, ductility, and impact resistance.

2. Enhanced structural integrity: Forged components have fewer internal defects, such as voids and inclusions, which can lead to premature failure.

3. Reduced material waste: Forging can produce near-net-shape components, requiring minimal machining and resulting in less material waste.

4. Greater design flexibility: Forging allows for the production of complex shapes and intricate details, providing greater design flexibility.

5. Cost-effectiveness: Although the initial tooling costs for forging can be high, the process is often more cost-effective in the long run due to reduced material waste and lower machining requirements.

Forging machining is a versatile and essential manufacturing process that has been used for centuries to create strong, durable metal components. With its various techniques and wide range of applications, forging continues to be a vital part of modern manufacturing. By understanding the different forging methods and their advantages, manufacturers can make informed decisions about the most suitable process for their specific needs, ensuring the production of high-quality, reliable components.