Introduction

A highly machinable metal with excellent strength and hardness, superior thermal conductivity and corrosion resistance. It is a popular material and can also be made into alloys to improve its mechanical properties.

Copper alloys are categorized into three types based on their machinability

Machinability rating of 70 – 150%

Extremely high machinability, optimal for copper CNC machining that requires high tolerances. Including bronze, brass and copper.

Machinability rating of 30 – 60%

Good machinability, but the choice was based on some other properties. Including unleaded brass.

Machinability rating of 30 – 60%

Poor machinability, it takes longer to machine and can increase machining costs. Including copper alloys formed with aluminum.

Properties

1. Excellent electrical conductivity — only second to silver (Ag)

2. Low friction coefficient

3. Good ductility

4. No magnetism.

5. Favorable corrosion resistance

…

Various copper for CNC machining

Different copper has different compositions and properties, so copper for CNC machining needs to be selected based on different reasons.

Pure copper

One of the purest forms with no more than 0.7% impurities. Soft and malleable, with higher mechanical properties when diluted by adding some alloying elements.

Oxygen-free copper

Highest purity, almost oxygen free, contains at least 99.99% copper. Depending on the content of added elements and impurities, their UNS designations are C10100 to C13000. It has very high electrical and thermal conductivity and is assigned the numbers C10100 and C10200.

Electrolytic copper

With a purity of 99.95%, and formed by electrolytic machining. The conductivity is 100% and the most common electrolytic copper material is C11000.

Copper nickel alloy

Use nickel as an alloying agent with a nickel content of 1.5% to 45%. The addition of nickel improves mechanical properties such as strength and hardness, but reduces ductility and machinability. The UNS assigned to this grade of copper numbers C70000 to C73499.

Free-machining copper

Usually containing telluride or sulfur as alloying agents, with great potential for machining. For sulfur, the number is C14700 and C14500 for telluride.

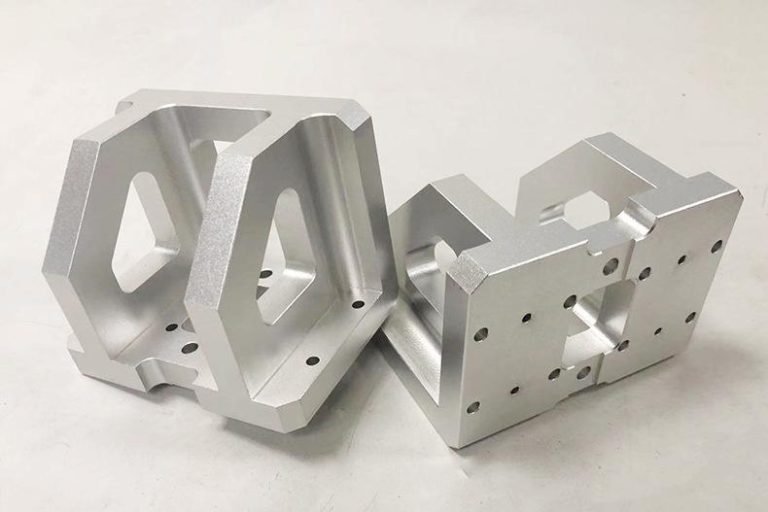

Pros and cons of copper in CNC machining

Like other metal materials, copper and its alloys have their specific advantages and disadvantages in CNC machining,including:

Pros

1. Copper exhibits good moldability in both cold and hot processes.

2. Good ductility gives copper the ability to present itself in any shape.

3. High recycling value, recycle used copper materials can help save the cost of CNC copper machining.

4. One of the cheapest materials with little or no electrical resistance.

Cons

1. Some copper materials are not compatible with the welding process.

2. Different grades of copper have different properties and some parts made of copper may corrode in certain environments.

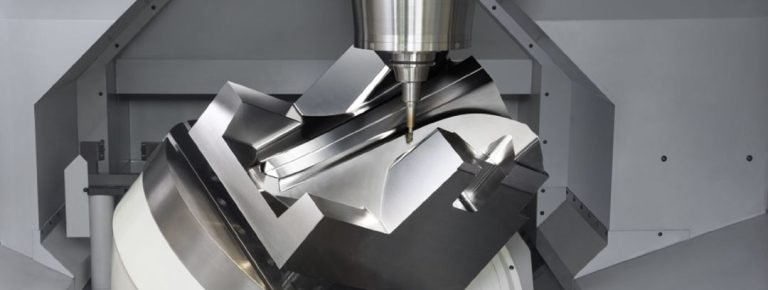

Critical considerations for CNC copper machining

1. Select the right copper grade

It is important to pick the right material before CNC copper machining. For example, it is inappropriate and wasteful to use pure copper for mechanical components.

2. Design for manufacturability

Checking the design requirements and specifications of your copper parts before CNC machining can ensure that the copper parts you manufacture fulfill the desired function.

3. Choose the right cutter material

As different grades of copper have different levels of strength and machinability. It is important to choose the right cutter material for machining copper parts. Carbide or HSS tools with sharp edges are ideal for CNC machining copper parts.

4. Set the appropriate feed rate

The feed rate is the speed at which the tool makes a precise cut on the workpiece and also needs to be set up before CNC machining.

Surface treatment of copper CNC machined parts

Media blasting

Helping to hide machining flaws or imperfections in copper CNC machined parts, and this process provides a more durable finish.

Electroplating

Providing a protective layer on the outer surface of copper machined parts to prevent oxidization, it can effectively extend the service life of copper components.

Electrolytic polishing

The removal of microscopic material layers from the surface of copper components results in a smoother and glossier surface for copper CNC machined parts.

Applications

The properties of copper and copper alloys make them suitable for use in a variety of industries.

Machinery and metallurgical industries

1. Mechanical engineering: copper parts can be found in almost all machines. Bearings or bushings made of wear-reducing copper alloys are used between almost all parts in mechanical relative motion. Elastic components, welding tools, die-casting molds are even more indispensable copper alloys.

2. Metallurgy plant: in the construction of a metallurgical plant, it is usually necessary to have a large transmission and distribution system and power running equipment that relies on copper for its work. Additionally, the key component in pyrometallurgy, the crystallizer, is mostly made of copper alloy.

3. Alloy Additives: copper is an important additive element in alloys such as steel and aluminum, which enhances their corrosion resistance and strength.

Electrical industry

1. Electric power transmission: power transmission requires a large consumption of highly conductive copper, which is mainly used for power, line cables, busbars, transformers, switches, connecting elements and couplings.

2. Electric motor manufacturing: highly conductive and high-strength copper alloys are widely used in the manufacture of electric motors, and the main components made of copper are the stator, rotor and shaft head.

3. Communication cables: converting electrical energy into light energy requires the use of large amounts of copper.

4. Domestic electricity consumption: the improvement of people’s living standards and the rapid popularization of home appliances have greatly increased the application of copper conductors.

Electronics industry

1. Vacuum electron device: mainly high-frequency and ultra-high-frequency transmitter tubes, waveguides, magnetrons, and more, which require high-purity oxygen-free copper and dispersion strengthening oxygen-free copper.

2. Printed wiring boar (PWB): the use of printed wiring is widely used as it saves a great deal of time in wiring and fixing loops, which requires the consumption of large quantities of copper foil. In addition, a variety of inexpensive, low-melting-point, good-flow copper-based brazing materials are used in the connection of circuits.

3. Integrated circuit (IC): s breakthrough has been made in the use of copper as an interconnect instead of aluminum in silicon chips. New microchips with copper can achieve a 30% gain in performance, and the wire size of the circuits can be reduced to 0.12 micrometers, allowing the number of transistors integrated on a single chip to reach 2 million.

4. Lead frame: copper is capable of meeting the requirements of lead frames.

…

Besides the mentioned above, copper can also be used in transportation, energy, light industry, agriculture, as well as newly developing industries and high-tech fields.

CYCO – the best service provider for CNC machining

The copper CNC machining process is carefully discussed in this article and it should be able to help you determine the right copper material for your project. If you still have any questions, we are also able to help you choose the copper material that matches your project best.

With over 20 years of experience as a CNC machining service provider, we have CNC machining experience in handling multiple materials with our state-of-the-art equipment and experienced machinists.

In order to avoid wasting your valuable time, you can choose CYCO as your partner without any hesitation!

Work with us for a worry-free experience now!