Abrasive waterjet cutting and pure waterjet cutting are two popular methods when it comes to cutting materials. Both techniques use high-pressure water to cut materials, but in different ways.

Abrasive water jet cutting uses a mixture of water and abrasive to cut, while pure water jet cutting uses only the pressurized water.

When deciding whether to choose pure water jet cutting or abrasive water jet cutting, it is important to consider the differences between them.

What is Abrasive Waterjet Cutting?

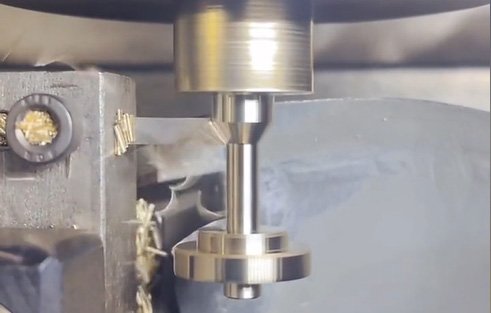

Abrasive water jet cutting is unique to industrial processes where high pressure abrasive mixed with water jet streams are used to cut hard materials such as glass, metal and stone. The mixture of abrasive with water helps to speed up the water, which increases the cutting power of the water jet. This makes it capable of cutting solid materials.

Abrasive waterjets follow the same principle of operation as pure waterjets, however, it is a different process due to the introduction of abrasive particles such as garnet. The garnet mixes with the high-pressure water stream and is able to erode any material in its path precisely and quickly.

What is Abrasive Waterjet Cutting Suitable For?

Abrasive water jet cutting utilizes hard particles mixed with the water stream to produce a cutting action. The abrasive may vary depending on the workpiece material, and it is generally accepted that the hardness of the abrasive should be greater than that of the workpiece material.

Abrasive water jet cutting applies to materials such as:

- Steel: one of the most common materials for abrasive water jet cutting.

- Aluminum: softer than many other metals and alloys, abrasive water jets can cut aluminum easily.

- Copper: used for a variety of applications such as copper piping, ducting, sheet metal, etc.

- Thick plastics: thicker plastics and composites require abrasive waterjet cutting.

- Stone: improved water jet systems can cut up to 100 feet of stone and earth in mining.

- Marble: cutting marble requires the ability to maintain the visual appearance of marble while dealing with its brittleness.

- Ceramics: while ceramics can deal with a lot of heat, other cutting methods often cause them to break due to brittleness.

- …

Pros and Cons of Abrasive Waterjet Cutting

Pros

-

Versatility

The greatest versatility of all cutting methods. It works on metals, non-metals, hard materials, soft materials, and any other type of material you can imagine.

-

Environmental Friendly

A kind of green technology. All the water used in the process is recycled back into the system and even the removed material can be collected and recycled.

-

Material Integrity

The material integrity of the workpiece can be maintained, this is because no heat affected zone is formed during the cutting process.

-

Ease of Use

Easy to set up and more convenient to use. All cutting programs can be executed with the control panel, no need to manually operate the cutting head.

-

High Precision

A high precision method that creates the lowest tolerances of any industrial cutting technology.

-

Sophisticated Design

It is even possible to work in cavities inside the material that cannot be reached by other cutting methods. Machines with higher axes are capable to create complex 3D designs.

Cons

-

Long Cutting Times

Abrasive water jet machining can be a time-consuming process compared to pure water jet. However, cutting times can be reduced by optimization methods.

-

Mechanical Failure

Due to the use of abrasive materials, the wear of parts is higher, which can lead to more frequent mechanical failures.

-

High Initial and Operating Costs

The initial cost of abrasive water jet machining can be high, especially if a higher axis machine is selected. In addition, abrasive materials are very expensive and cannot be reused.

-

Thickness and Accuracy

Accuracy decreases as the thickness of the material increases. However, the accuracy of abrasive water jet cutting is still higher than most other cutting methods.

-

Material Limitations

Not suitable for soft materials as the abrasive may stick to the workpiece.

What is Pure Waterjet Cutting?

Pure water jet cutting uses only pure water in the cutting process, without the addition of abrasive materials such as garnet or other types of abrasives. Pure water jet cutting generates less heat and can be used on heat sensitive materials without damaging them.

What is Pure Waterjet Cutting Suitable For?

Pure water jet cutting is suitable for a wide range of materials such as:

- Felt: the best way to cut felt. This is because thermal cutting processes such as laser cutting can cause the felt to melt and form beads that can ruin its appearance.

- Foam: excellent choice for cutting any type of foam. Foam burns due to the heat generated when traditional cutting methods are used, making pure water jet cutting the preferred choice for foam cutting.

- Food: using pure water jet cutting maintains the sanitation and integrity of food products.

- Paper: one of the earliest applications of pure water jet technology. Water jet cutting can cut paper of any thickness without feathering effects or wetting the paper. Pure waterjets can even cut multiple layers of cardboard with high precision.

- Rubber: the heat generated by conventional cutting methods produces bad odors and toxic fumes. However, cutting rubber with a pure water jet does not cause any of these adverse effects.

- Metal Foil: although metal is hard, metal foil is soft. And the metal dust generated in the process can be collected in the drain after mixing with water.

Pros and Cons of Pure Waterjet Cutting

Pros

-

Costs

Pure water jet cutting does not require the cost of abrasives. By eliminating this cost, pure water jet cutting tends to be cheaper.

-

Speed

There is no need to mix with abrasives, so it is faster.

-

No Heat Affected Zone

Pure water jet cutting does not use physical cutting tools, it is a cold cutting process, even the water itself is a coolant, so there is no heat affected zone formed.

-

Precision

One of the most accurate cutting methods, with tolerances second only to laser cutting.

-

Versatility

Any type of soft, lightweight, thin or delicate material can be cut, including metals, non-metals, fabrics, etc.

-

No Damage to the Workpiece

Pure water jet cutting has a very small kerf width and no damage occurs to the workpiece.

-

Complex Cutting

Pure water jet cutting can work in cavities where other cutting methods cannot operate.

-

Ease of Use

Automatic operation can be performed with a computer. The operator only needs to select the cutting program pre-installed in the software.

Cons

-

Slower Cutting

Pure water jets rely only on the cutting force of the water. As a result, this method cuts slower than abrasive water jet cutting.

-

Material Limitations

Due to the extremely slow cutting speed, pure water jet cutting becomes unfeasible when cutting hard materials. Therefore, this method is limited to soft materials as described above.

Differences Between Abrasive and Pure Waterjet Cutting

Machining Processes

In abrasive water jet cutting, sand or garnet is used as the abrasive material, and the grit inside the nozzle generates high temperatures and pressures. The high velocity water stream and abrasive material create a powerful jet that can cut any material.

On the contrary, pure water jet cutting does not use any abrasive material in its process. It relies on the pressure generated by the high-velocity water stream to cut metal or stone without damaging its surface finish or integrity.

Cutting Materials

Pure waterjets are the perfect solution for machining thin and soft materials such as foam, rubber, plastic and even food. To effectively machine harder and thicker materials, the cutting stream will probably require the addition of abrasive media.

Abrasive waterjets are used to cut all types of metals, including steel, aluminum and titanium, as well as many other hard materials, including stone, composites and glass.

Running Costs

Abrasive waterjets use about 1 pound of garnet per minute on average when cutting, which makes the abrasive the largest contributor to costs that can be completely eliminated by pure water cutting.

Additionally, due to the destructive nature of abrasive water, the nozzles of the machine need to be replaced periodically.

Finally, used abrasives must be disposed of properly, which also costs money.

Applications

Abrasive waterjet cutting is primarily used in industry, while pure waterjet cutting is often used for commercial projects.

Applications for abrasive waterjet cutting include metal and sheet metal fabrication, where holes need to be cut into metal parts to make them stronger or to reduce weight.

Applications for pure waterjet cutting include stone cutting, concrete cutting, and glass etching.

Kerf

The kerf is defined as the width of the cut by the water jet cutting stream. The kerf is determined by the size of the used orifice, as a larger orifice will produce a larger cutting stream. Typically, an abrasive water jet will produce a cutting stream approximately 0.03 – 0.04 inches wide, while a pure water cutting stream can be as fine as 0.003 inches. Because pure water streams produce smaller cuts, they can produce sharper edges while minimizing material waste.

Conclusion

Both abrasive waterjet cutting and pure waterjet cutting have their strengths and weaknesses to consider before deciding which one is the best. Therefore, the right machine should be selected according to your requirements.

Why CYCO

CYCO offers a variety of CNC machining services, including water jet cutting services, to meet your manufacturing needs.

We offer precision waterjet cutting services for prototyping and mass production with optimal results, so there’s no need for extra worry when working with us!