Exploration of Metal Penetration

Metal penetration, liquid metal or metal oxides drill into the sand gap on the surface of the cavity through capillary penetration or vapor-phase penetration, and

Home > Blog

Metal penetration, liquid metal or metal oxides drill into the sand gap on the surface of the cavity through capillary penetration or vapor-phase penetration, and

Sand adhering to castings refers to the phenomenon of adhesion between the sand mold and the molten metal during the casting process, which affects the

Casting coating is usually applied to the surface of mold or core sand. It aims to isolate the liquid metal from the casting mold, prolong

Casting inclusions, one of the unavoidable problems in the casting process, negatively affect the quality and performance of castings. Introduction of Casting Inclusions Casting inclusions

Casting surface finish is an important part of improving the casting quality to ensure its functionality and durability. It covers a range of processes from

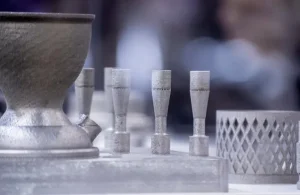

The convergence of 3D printing and casting creates endless possibilities for manufacturing. It achieves the perfect combination of complex structures, customization and efficient production. Basic

Heat treatment uses heating and cooling processes to change the internal microstructure of steel castings. It is a process to optimize the mechanical properties of

Cast iron is a common casting material. Depending on its composition and properties, there are several types of cast iron such as gray cast iron,

Non-ferrous metal melting is the heating of non-ferrous metals and their alloys to a high temperature liquid state. Through alloying and fine control, metal materials

Hot forging involves plastic deformation of metals at high temperatures, while cold forging involves plasticizing metals at lower temperatures. Both are suitable for different industrial

Talk To Our Engineers