The Points Of Aluminum CNC Machining Technology

Characteristics of aluminum machining Second only to steel in terms of importance to industry, aluminum and aluminum alloys are the most widely used non-ferrous metals.

Home > Blog

Characteristics of aluminum machining Second only to steel in terms of importance to industry, aluminum and aluminum alloys are the most widely used non-ferrous metals.

Smoothing machining technology is a subset of manufacturing processes aimed at achieving precise and smooth surface finishes on workpieces, typically metals or other materials. Here’s

CNC machining is widely used in the application of stainless steel material due to its corrosion resistance, high strength, and aesthetic properties, making it suitable

The injection molding process refers to the process of creating semi-finished parts of a certain shape by melting raw materials and performing operations such as

As the foundation of the automotive industry, there are a wide variety of automobile components. From a production process perspective, they include casting, forging, stamping,

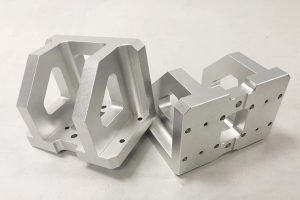

Aluminum is a widely used material in CNC machining due to its favorable properties and versatility. Its lightweight, good machinability, corrosion resistance, and thermal conductivity

Injection molding is a molding method of injection and molding. The advantages of the injection molding method are fast production speed, high efficiency, automatic operation,

Auto parts machining mainly refers to cylinder blocks, cylinder heads, crankshafts, camshafts, connecting rods, etc. Most of the machine tools required to process these parts

CNC machining is the manufacture and machining of parts and products under computer control. Numerical control machining involves the use of computer numerical control (CNC)

The cost of CNC precision machining may be higher than traditional machining methods. However, the benefits offered by the process definitely make it worth the

Talk To Our Engineers