Precision parts machining involves the process of removing material from a workpiece to create intricate and accurate components. To achieve the necessary level of precision, there are several key requirements that machining processes must meet:

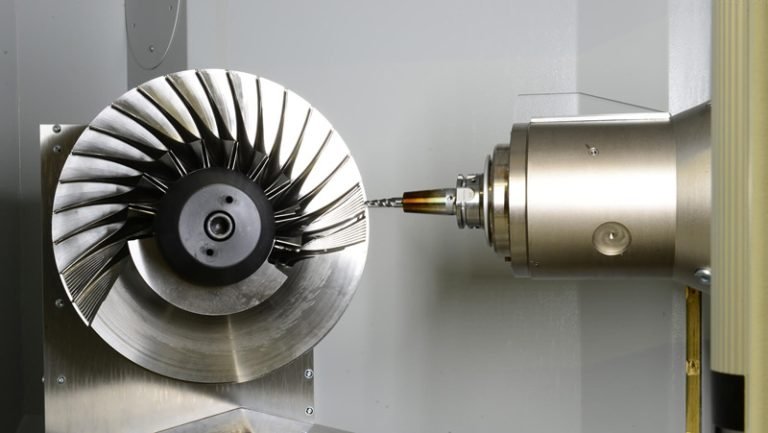

1. High-Quality Machinery: Precision machining requires the use of advanced machinery, such as CNC machines with high rigidity and precision capabilities. These machines can achieve tight tolerances and deliver consistent results.

2. Skilled Machinists: Trained and experienced machinists are essential for precision parts machining. They should have a deep understanding of machining principles, tool selection, and process optimization.

3. Dimensional Accuracy: The machining process must achieve the desired dimensional accuracy specified in the engineering drawings. This involves precise control of tool movements and compensation for any machine or tool inaccuracies.

4. Surface Finish: Precision parts often require a specific surface finish to meet functional and aesthetic requirements. The machining process should be capable of achieving the required surface roughness and eliminating any imperfections.

5. Material Selection: The choice of material is crucial for precision machining. Different materials have varying machinability and mechanical properties, so selecting the appropriate material is vital for achieving the desired results.

6. Tool Selection and Maintenance: High-quality cutting tools, such as end mills, drills, and reamers, are essential for precision machining. Regular maintenance and proper tool selection based on the material and cutting requirements are necessary to ensure consistent performance.

7. Rigorous Quality Control: Quality control is critical throughout the machining process. Inspection techniques, such as in-process measurements and final inspections using tools like CMMs, help verify that the parts meet the required specifications.

8. Stability and Vibration Control: To achieve precision, machines must be stable and well-maintained. Proper alignment, calibration, and vibration control are essential to prevent deviations in the machined part.

9. Toolpath Optimization: Optimizing the toolpath is crucial for efficient and accurate machining. Minimizing tool movements, reducing air cuts, and avoiding sharp changes in direction can enhance precision and reduce machining time.

10. Coolant and Lubrication: The use of appropriate coolants and lubricants is vital for precision machining. They help dissipate heat, prolong tool life, and improve surface finishes.

11. Chip Control: Effective chip control is necessary to prevent chip buildup, which can affect tool performance and part accuracy. Proper chip evacuation strategies should be employed.

12. Documentation and Traceability: Detailed documentation of machining parameters, tooling used, and any adjustments made during the process is essential for consistency and traceability.

13. Continuous Improvement: Continuous improvement efforts should be implemented to optimize processes, reduce waste, and enhance overall machining efficiency and precision.

By meeting these requirements, precision parts machining can produce components with exceptional accuracy and surface finish, meeting the demands of various industries, including aerospace, medical, electronics, and more.