What is electroplating?

In industrial design, we often use electroplating techniques. Electroplating is the process of plating a thin layer of other metals or alloys on the surface of certain metals using the principle of electrolysis. It uses electrolysis to make the surface of metal or other materials attached to a layer of metal film, which can play a role in preventing metal oxidation (such as rust), improve wear resistance, electrical conductivity, reflectivity, corrosion resistance (such as copper sulfate) and enhance the role of aesthetics.

Electroplating is subdivided into copper plating, gold plating, silver plating, chromium plating, nickel plating, zinc plating and more. Zinc, nickel and chrome plating are most widely used in industrial design.

So what’s the difference between these three technologies?

Basics of the three types of plating

Zinc plating

Definition: Zinc plating refers to the surface treatment technology of plating a layer of zinc on the surface of metals, alloys, or other materials to provide aesthetic and anti-rust functions.

Trait: The color is silver-white, low cost but poor corrosion resistance.

Application: Screws, circuit breakers, industrial supplies, etc.

Nickel plating

Definition: A layer of nickel plated on a metal or some non-metal by electrolysis or chemical methods.

Trait: Silver white with a yellowish tint, beautiful and can be used for decoration, but the price is high because of the complexity of the process.

Application: Energy saving lamp heads, coins, hardware and more.

Chrome plating

Definition: Chromium is a bright white metal with a slight bluish tinge. The method of plating a layer of chromium on a metal or some non-metal by electrolysis or chemical methods is called chrome plating.

Trait: There are two purposes for chrome plating. One is used for decoration, bright appearance, better abrasion resistance, but rust resistance is not as good as zinc plating, it is easy to be oxidized. The other is to increase the hardness and wear resistance of metal parts.

Application: Bright decorative parts for home appliances, electronics and other products, faucets, etc.

Characteristics of the three types of plating

Zinc plating

Zinc is an active metal that reacts with acids, so it has poor corrosion resistance and is the cheapest of the three.

Nickel plating

Nice abrasion resistance, corrosion and rust resistance with thin thickness, the processing technology is divided into two categories: electroplating and chemical processing.

Chrome plating

Chrome plating has good chemical stability and does not act in bases, sulfides, nitric acid and most organic acids, but is soluble in hydrohalic acids (such as hydrochloric acid) and hot sulfuric acid. Chrome does not tarnish and can last for a long time. The process is generally electroplating.

Differences between the three types of plating

In terms of cost: chrome is the most expensive and zinc is the cheapest. It is also important to distinguish rack plating and barrel plating, rack plating is more expensive than barrel plating.

From the perspective of color: generally, chrome plating is bright white, nickel plating has a bit of yellowish tint, and zinc plating is silvery white.

Just for reference

1. If the purpose is to prevent rust, choose zinc or chrome plating; if the focus is to prevent wear and tear, nickel or chrome plating is the best choice.

2. In China’s electroplating process, zinc plating accounts for 50%, chrome plating and nickel plating accounts for 30%.

3. Wastewater and heavy metals in the effluent from electroplating production are harmful to the environment.

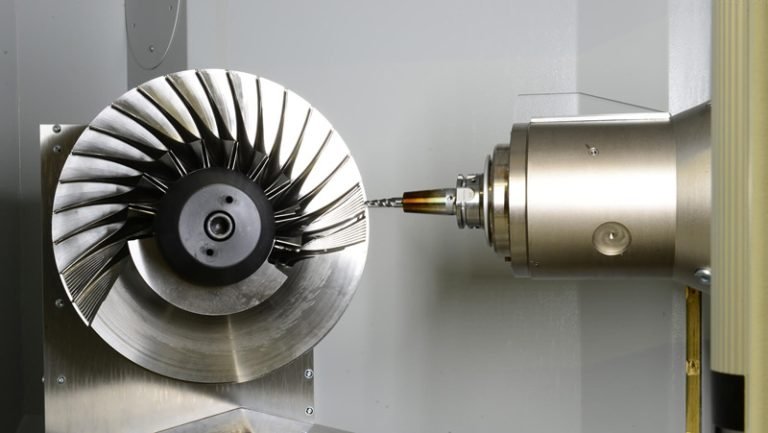

Choosing the right plating machining process can be challenging, which is why you need to outsource to a specialized CNC service provider like us. CYCO offers a wide range of CNC machining services and can help you choose the most appropriate plating method according to your needs, which can greatly help you save costs and time.

We specialize in CNC machining processes for all types of materials.CYCO can select the most appropriate machining method for your needs and materials, and our dedicated team can provide expert advice on the selection of technologies.

Upload your design to get a instant quote now and feel free to contact us for more information.