CNC machining and traditional machining are two different methods used in the manufacturing industry to shape and form materials into desired products. While both approaches share the goal of creating precise parts, they differ significantly in terms of the processes, equipment, and level of automation involved. In this response, we will delve into the differences between CNC machining and traditional machining in detail.

Traditional machining, also known as conventional machining or manual machining, refers to the use of manually operated tools and machines to shape materials. It has been the primary method of manufacturing for centuries before the advent of computer numerical control (CNC) technology. Traditional machining encompasses various techniques such as turning, milling, drilling, grinding, and shaping, all performed manually by skilled operators.

One of the fundamental distinctions between CNC machining and traditional machining lies in the level of automation. In traditional machining, the operator guides the cutting tool manually, adjusting the speed, depth, and direction of the cut. This process requires a high degree of skill, experience, and expertise on the part of the machinist. On the other hand, CNC machining involves the use of computer-controlled machines that follow pre-programmed instructions to execute the manufacturing process. The operator’s role in CNC machining is primarily to set up the machine, input the program, and monitor the operation.

The use of computer numerical control in CNC machining offers several advantages over traditional machining. Firstly, CNC machines can operate continuously, 24/7, allowing for higher production rates and increased productivity. Traditional machining often involves manual setup and adjustment for each part, which can be time-consuming and limit the production capacity. In contrast, CNC machines can switch between different operations and tools automatically, reducing downtime and increasing efficiency.

Precision is another key difference between the two methods. CNC machines are highly accurate and capable of producing parts with consistent dimensions and tight tolerances. The computer-controlled nature of CNC machining eliminates the possibility of human error and ensures repeatability. In traditional machining, achieving the same level of precision requires skilled operators and meticulous attention to detail, which can be subject to variations and inconsistencies.

Flexibility is another aspect where CNC machining excels. Once a CNC machine is programmed, it can produce identical parts repeatedly, making it suitable for high-volume production. Moreover, CNC machines can easily switch between different tasks by simply changing the program, allowing for rapid prototyping and shorter lead times. Traditional machining, on the other hand, often requires retooling and reconfiguring the machine for each new part, making it less flexible and more time-consuming for small-batch or custom production.

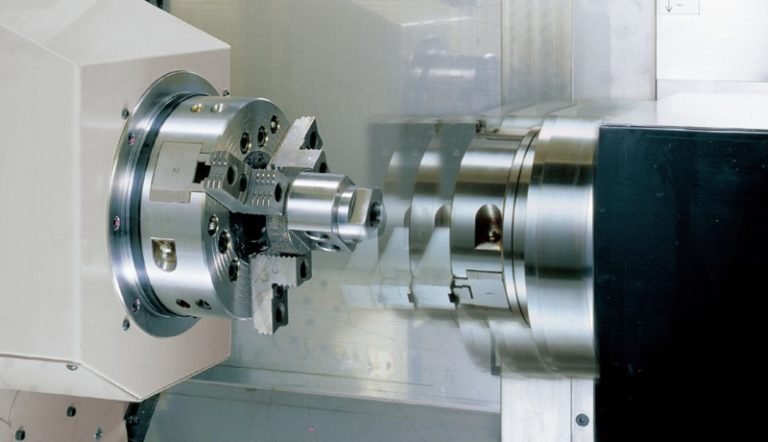

Complexity of part geometries is also a differentiating factor between CNC and traditional machining. CNC machines can handle intricate and complex designs with ease. They can execute three-dimensional operations, interpolate curves, and create intricate shapes that would be challenging or impossible to achieve manually. Traditional machining techniques are limited by the skill and dexterity of the operator, making them less suitable for complex parts.

Cost considerations play a role in the choice between CNC and traditional machining. CNC machines are generally more expensive to acquire and maintain compared to traditional machines. They require skilled programmers to create the machining programs, and any errors in the program could lead to costly mistakes. Traditional machining, although requiring skilled operators, does not have the same level of upfront investment in equipment and training.

Another notable distinction between CNC machining and traditional machining is the level of human involvement. CNC machining reduces the reliance on skilled operators, as the bulk of the work is automated. This can be advantageous in terms of reducing labor costs and minimizing the impact of human error. However, it also means that the demand for traditional machinists may decrease, as the industry shifts towards CNC technology.