Why cutters are “passivated” purposely

Isn’t the faster the better for tools used in CNC machining centers? Why is passivation necessary? Actually, passivation is not a literal understanding of the

Home > CNC Machining > Page 4

Isn’t the faster the better for tools used in CNC machining centers? Why is passivation necessary? Actually, passivation is not a literal understanding of the

Metal inert-gas welding (MIG) welding — Also known as semiautomatic welding 1. Maintain 1/4-3/8-inch welding wire rod extension (length of wire extending from the welding

Basic performance of cutter materials The choice of cutter material has a great influence on cutter life, machining efficiency, machining quality and machining cost. Cutters

What is a milling cutter? A milling cutter is a rotary tool with one or more bits used in milling operations, each of its bits

There are many different types of plastics with different forms, colors and properties. The use of machinable plastics depends on their properties, some plastics have

Characteristics of aluminum machining Second only to steel in terms of importance to industry, aluminum and aluminum alloys are the most widely used non-ferrous metals.

CNC machining is widely used in the application of stainless steel material due to its corrosion resistance, high strength, and aesthetic properties, making it suitable

Aluminum is a widely used material in CNC machining due to its favorable properties and versatility. Its lightweight, good machinability, corrosion resistance, and thermal conductivity

Auto parts machining mainly refers to cylinder blocks, cylinder heads, crankshafts, camshafts, connecting rods, etc. Most of the machine tools required to process these parts

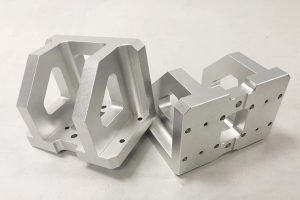

CNC machining is the manufacture and machining of parts and products under computer control. Numerical control machining involves the use of computer numerical control (CNC)

Talk To Our Engineers